A mulching film earth covering device used for a film laying machine

A technology of film spreading machine and mulching film, which is applied in the direction of sowing, application, plant protection cover, etc., can solve the problems of unevenness and small amount of covering soil, and achieve the effect of improving reliability, stabilizing the amount of covering soil, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

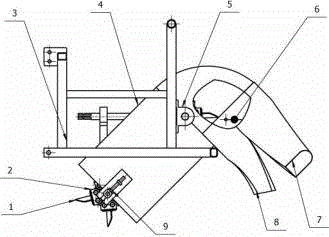

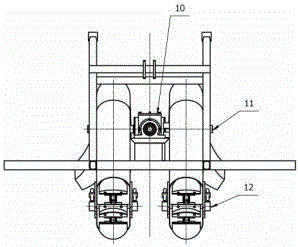

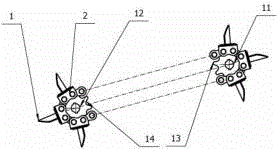

[0019] Such as figure 1 As shown, the film covering device of the film planter is symmetrically provided with two conveyor housings 4 in the transverse direction of the frame 3, and each conveyor housing 4 is obliquely installed on the frame 3, and each conveyor housing 4 is provided with an excavation conveying transmission device inside, and the excavation conveying transmission device is consistent with the inclination direction of the conveyor housing 4, and the tail of each conveyor housing 4 is provided with a side soil distribution port 7 and a normal position soil distribution port 8, A soil-distributing adjustment plate 6 is installed at the junction of the lateral soil distribution port 7 and the frontal soil distribution port 8, as shown in Fig. 4 . As shown in Figure 2 and Figure 3, the excavation conveying transmission device includes a driving shaft 11 and a driven shaft 12, the driven shaft 12 is located at the front end of the conveyor housing 4, and both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com