A metal composite plate preparation and rolling integrated production system and preparation method

A metal composite plate and production system technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of high manufacturing cost, difficult production management, and poor logistics, and achieve smooth transportation and logistics. Reduce the difficulty of design and construction, the effect of short distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

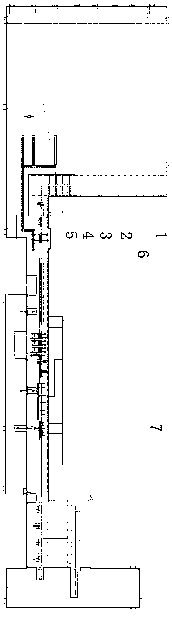

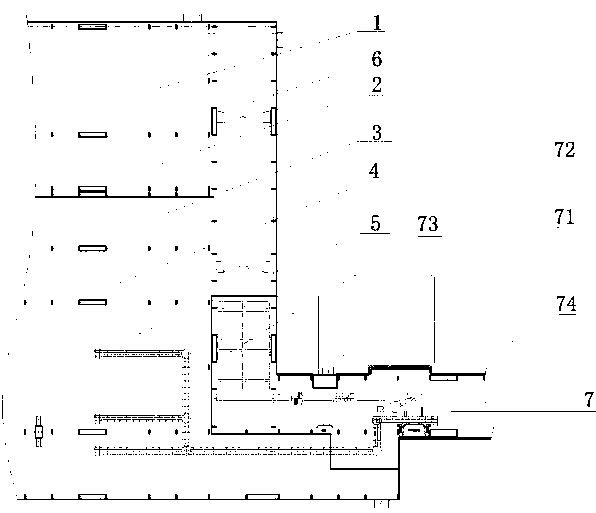

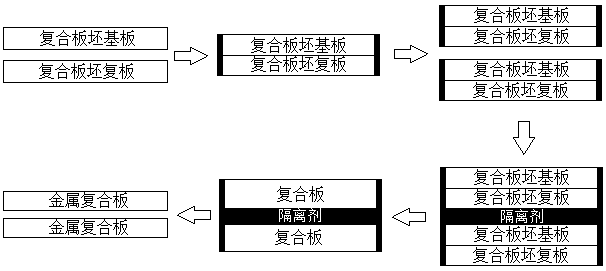

[0025] combine Figure 1-2 , a metal composite plate preparation and rolling integrated production system of the present invention, comprising a composite plate billet production line 1, a composite plate finishing production line 2, a hot-rolled coil production line 7, a leveling and cross-cutting production line 4, a finished composite plate and Composite board substrate warehouse 6, cross-cut steel warehouse 3, steel coil warehouse 5, the composite board billet production line 1, composite board finishing production line 2, cross-cut steel warehouse 3, smooth cross-cut production line 4, steel coil warehouse 5 in sequence Arranged side by side, composite plate billet production line 1, composite plate finishing production line 2, cross-cut steel plate warehouse 3, smooth cross-cut production line 4, steel coil warehouse 5 are all connected with finished composite board and composite board substrate warehouse 6, hot-rolled coil The production line 7 is provided with a slab s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com