Head structure of a cable extruder

A technology of cable extrusion and extrusion head, applied in the direction of coating, etc., can solve the problems of easy damage of cable core, influence of plastic plasticization, and uneven unevenness, and achieve good stability, avoid mold dragging, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

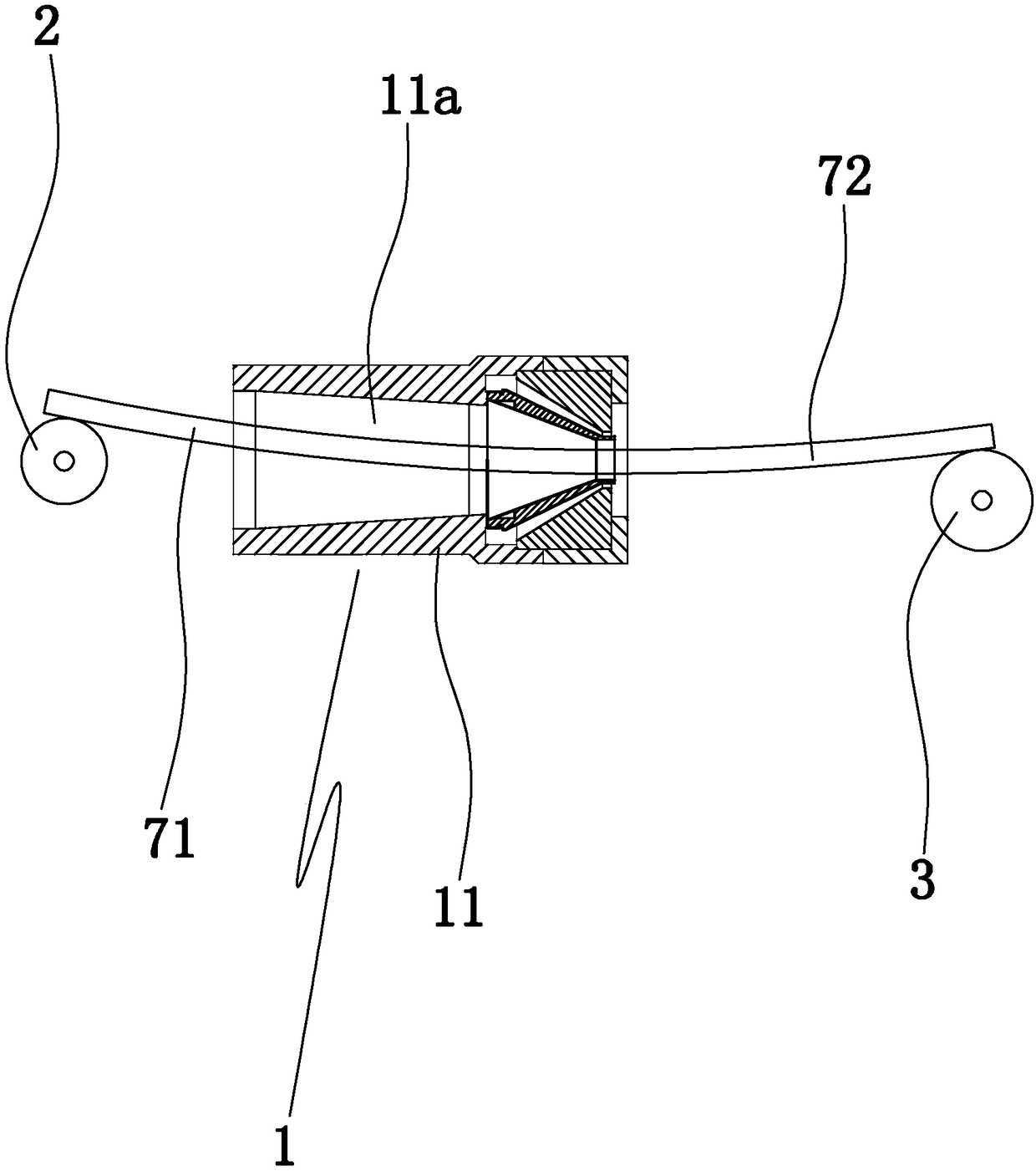

[0025] Embodiment 1: as figure 1 As shown in , a head structure of a cable extruder includes a base frame and an extruder head 1, and also includes a feeding roller 2 for supporting the wire core 71 and a forming roller for supporting the cable 72 3. The feeding support roller and the forming support roller are located on opposite sides of the extrusion head, and the extrusion head includes a head seat 11, which is provided with an extrusion channel 11a. The wire core passes through the extrusion channel. In addition to being pulled tightly by the traction force, the wire core is also supported on the feeding support roller and the forming support roller. The overall stability is high, the sinking range is small, and the dragging phenomenon is not easy to occur. After the wire core passes through the extruder head, it is covered with plastic, and the cable is formed after curing (outer plastic and inner wire core).

Embodiment 2

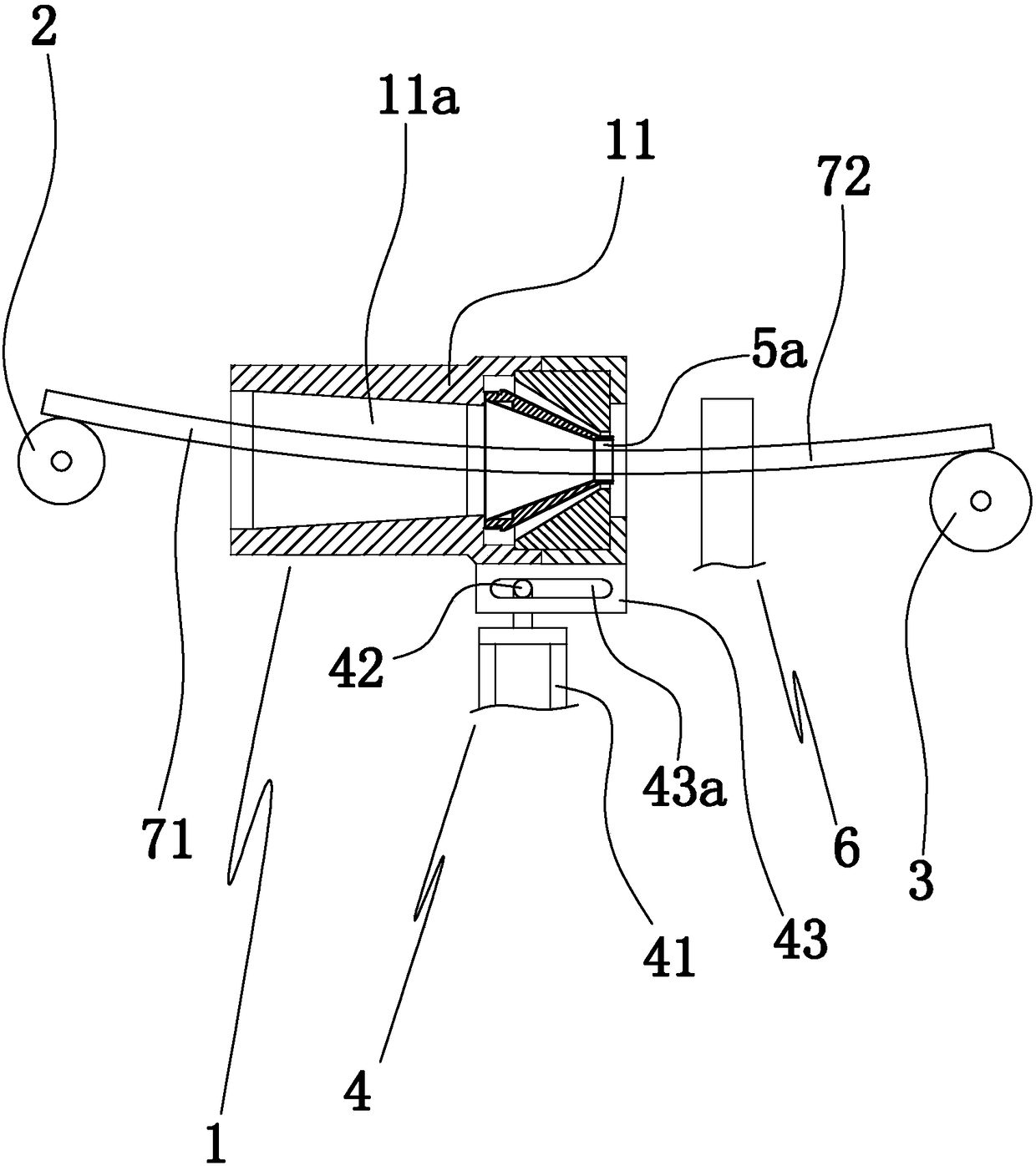

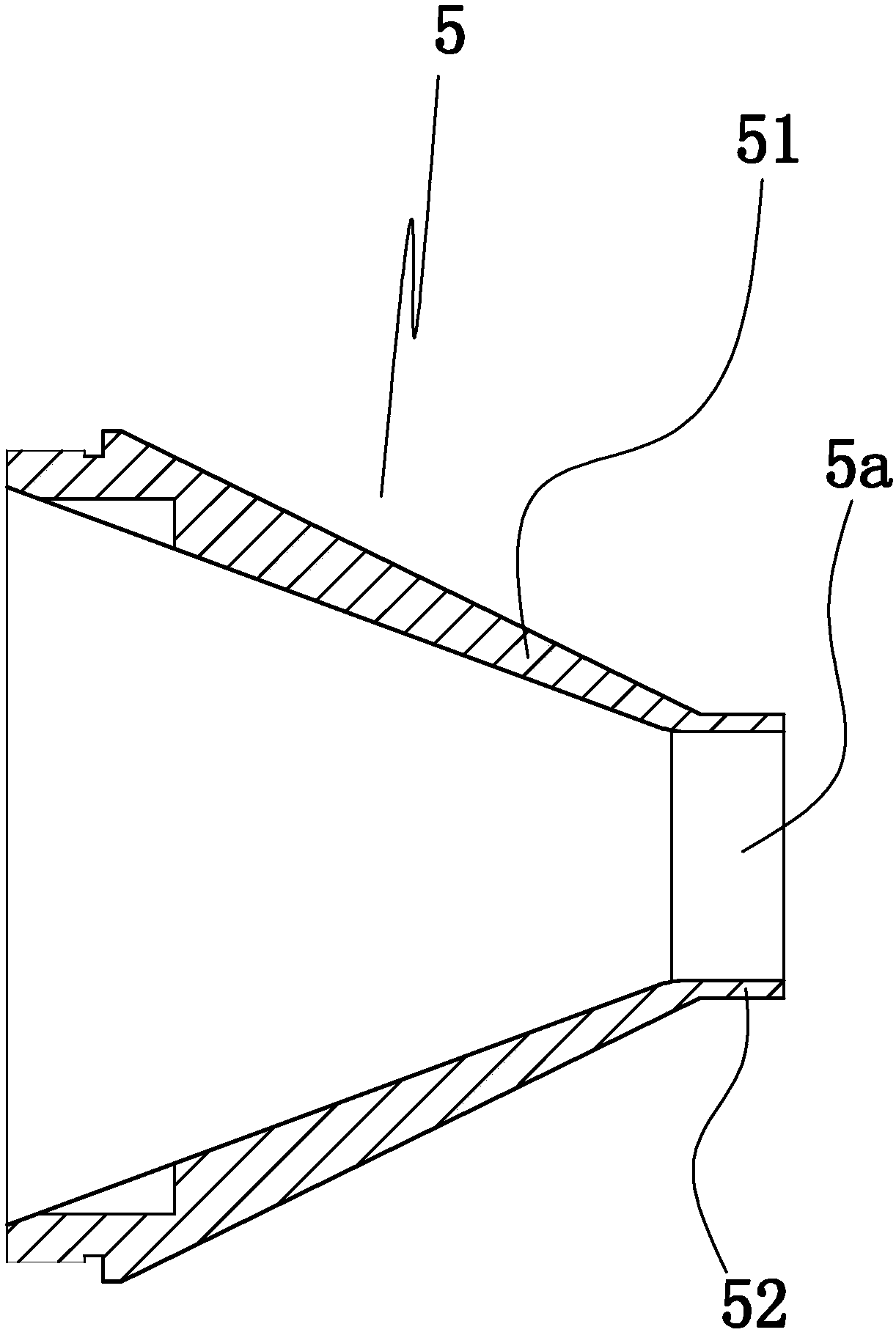

[0026] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 2 to Figure 6 As shown in , the base frame is provided with an adjustment structure 4 for driving the extruder head to change the angle. The adjustment structure includes an adjustment oil cylinder 41 fixed to the base frame, an adjustment shaft 42 connected with the piston rod of the adjustment oil cylinder, and an adjustment shaft 42 arranged on the The matching block 43 on the extruder head is provided with a bar-shaped hole 43a on the matching block, and the adjusting shaft stretches into the bar-shaped hole and the adjusting shaft is slidably matched with the bar-shaped hole.

[0027] The adjustment shaft is arranged horizontally, the adjustment shaft extends into the strip hole, the length direction of the strip hole is horizontal, the hole depth direction of the strip hole is horizontal, the length of the strip hole is perpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com