Whole steel-mould cast-in-place ultra-thin concrete underground impermeable walland construction method thereof

The technology of an underground anti-seepage wall and construction method is applied in the field of all-steel cast-in-place ultra-thin concrete underground anti-seepage wall and its construction field, which can solve the problems of complex construction of the anti-seepage wall, short service life, mud pollution, etc., and achieve guarantee Quality and appearance, guaranteed filling factor, and the effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The construction method of the all-steel mold cast-in-place ultra-thin concrete underground anti-seepage wall and its construction method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] An all-steel form cast-in-place ultra-thin concrete underground anti-seepage wall and its construction method are characterized in that the construction steps are as follows:

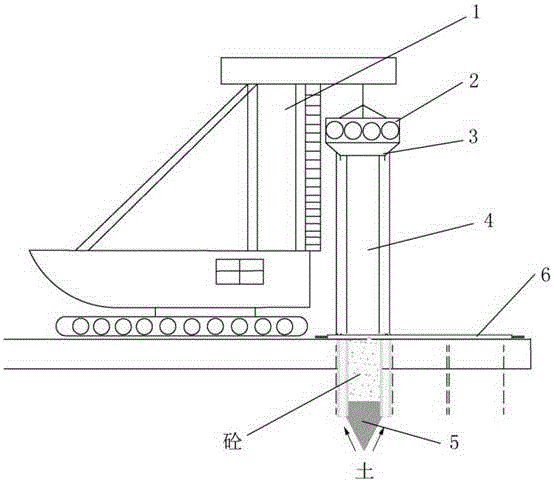

[0028] Step 1: First, use the lifting device (1) to lift the high-frequency vibrating hammer (2), the special holder (3), and the ultra-thin hollow countersunk (4), and use a thin iron wire to lift the pointed pile point (5 ) is installed below the ultra-thin hollow counterbore (4);

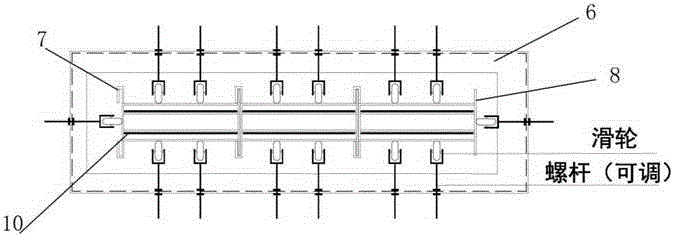

[0029] Step 2: Move the lifting equipment (1), lift the first ultra-thin hollow countersunk (4) and place it at the predetermined position, and use the auxiliary positioning device (6) to perform auxiliary adjustment and positioning, and start t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com