Assembly type wall and installation method thereof

An installation method and prefabricated technology, applied to walls, building components, buildings, etc., can solve problems such as improper installation, low safety, and unsolid structure, and achieve enhanced solidity, high safety, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

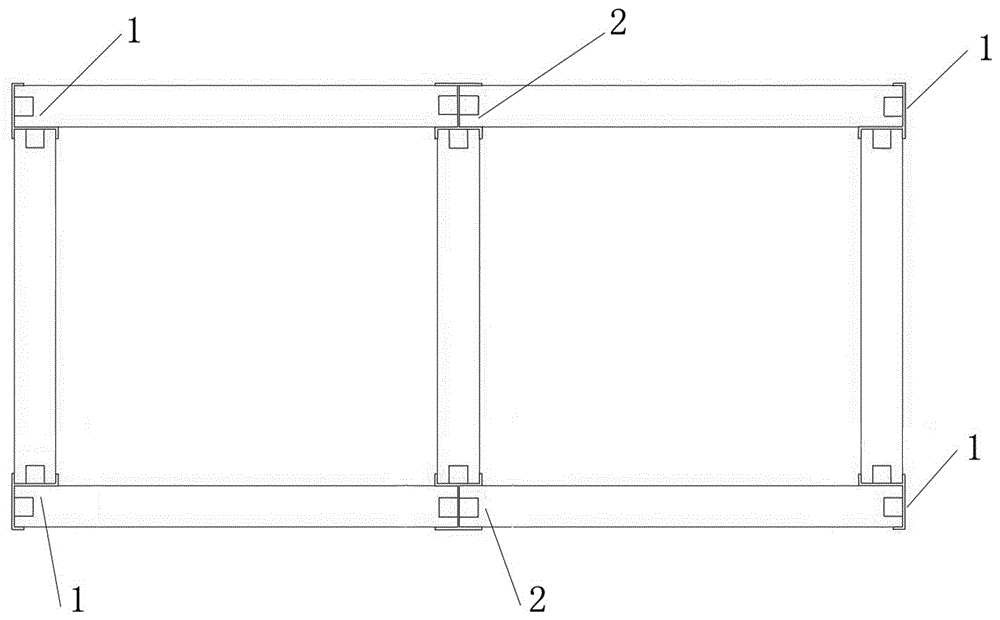

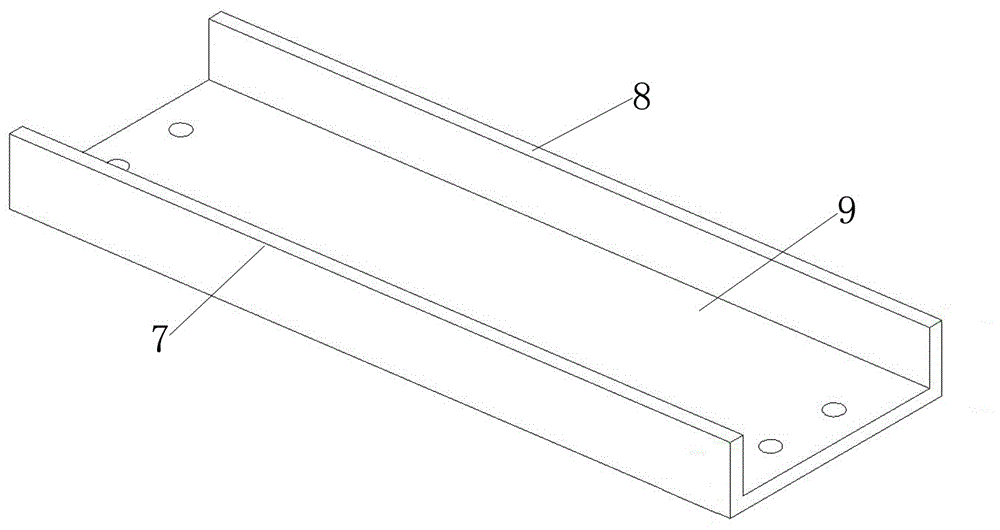

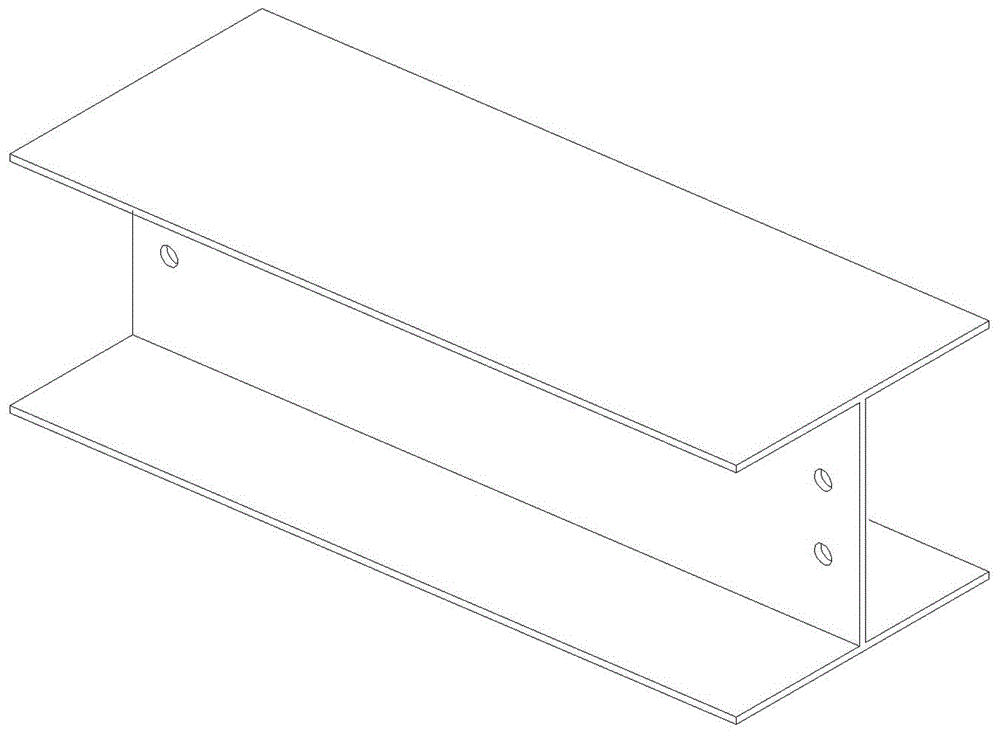

[0024] as attached figure 1 As shown, the installation method of the prefabricated wall includes the following steps: a Fixing columns: Fix four double U-shaped steel structures as columns at the four corners of the room to be installed, and connect the four columns to form a quadrilateral equal to the size of the room , the four double U-shaped steel structures 1 are the main skeleton of the room to be installed, the column is fixed according to the required wall size, the bottom of the column is welded with flat steel, and the flat steel is fastened to the ground through anchor screws, and the fixed column and the foundation The horizontal line of the surface forms 90 degrees; b Connecting beam: U-shaped steel structure is placed on the ground between every two columns as a beam, used to clamp the wall in the beam, and the round hole on the U-shaped steel structure is connected with the screw rod Double U-shaped steel structure 1 The nut holes on the connecting plate are fas...

Embodiment 2

[0027] as attached figure 2 As shown, the installation method of the prefabricated thermal insulation and decoration integrated wall includes the following steps: a Fixing columns: Fix four double U-shaped steel structures 1 as columns at the four corners of the required room, and connect the four columns to form a For a quadrilateral with equal room size, a three-U-shaped steel structure 2 column is installed on the two long sides of the quadrangle formed by the columns. Four double-U-shaped steel structures 1 and two triple-U-shaped steel structures 2 are the main skeleton of the room to be installed. The required wall size is fixed to the column, and the bottom of the column is welded with flat steel, and the flat steel is fastened to the ground through anchor screws, and the fixed column forms a 90-degree angle with the horizontal line of the base; The ground between the two columns is used as a beam, and the round holes on the U-shaped steel structure are respectively fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com