Lamp set lifting device of medical lamp inspection machine

A technology of lifting device and light inspection machine, which is applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve the problems of complex structure of lifting devices, obvious equipment damage effects, and inability to detect foreign objects in bottles, etc., to achieve the overall design of the structure Reasonable and simple, improve the service life and reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

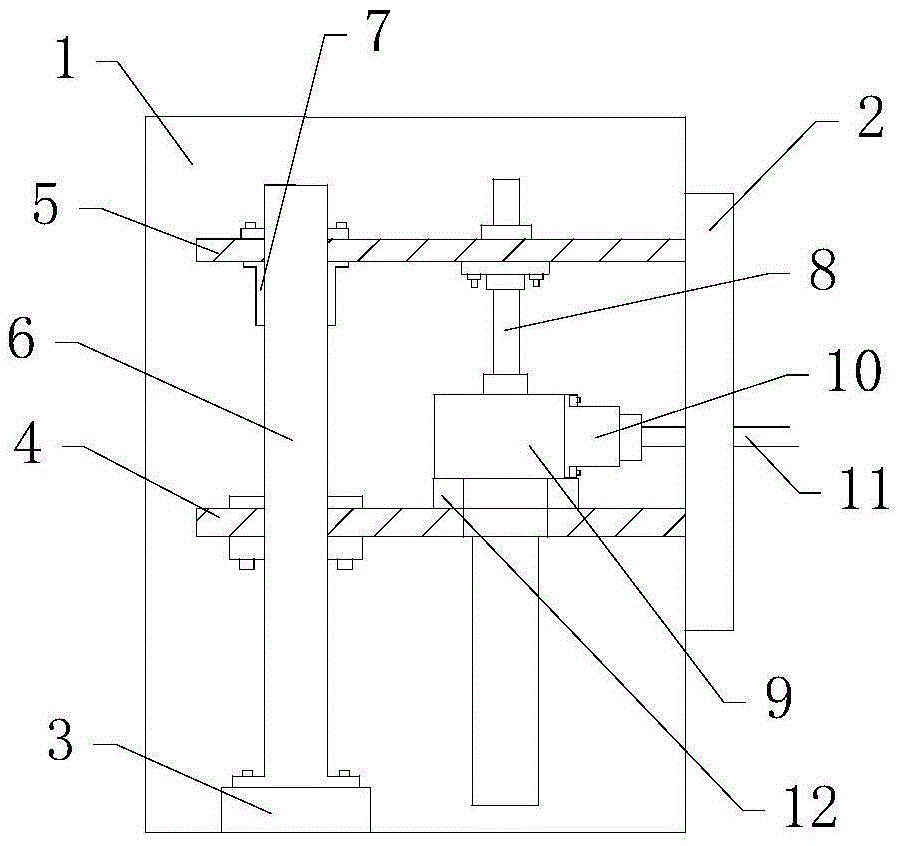

[0019] Such as figure 1 As shown, the lamp group lifting device of the medical lamp inspection machine includes a lifting group and a supporting group, and the supporting group includes a supporting base 3 fixed on the bottom of the box body 1, a supporting column 6 installed on the supporting base 3, and a support column perpendicular to the supporting column. 6 support plate 4;

[0020] The lifting group includes a lifter 9 installed on the support plate 4, a slide bar 8 arranged in the lifter 9, and a fixing plate 5 fixing the top of the slide bar 8; a connecting block 10 is installed on the side of the lifter 9 , the connecting block 10 is equipped with a lamp group support frame 11, the position where the side of the lifter 9 is connected to the connecting block 10 is provided with a groove, and one end of the connecting block 10 is provided with a groove opposite to the groove. A boss, said boss is installed in the groove.

[0021] A front baffle 2 is arranged in front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com