High low temperature cycle control system and high low temperature fast control method

A high and low temperature circulation and control system technology, applied in control/regulation systems, temperature control, non-electric variable control, etc., can solve the problems of inability to switch between high and low temperatures at any time, achieve simple devices and methods, and wide temperature control range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

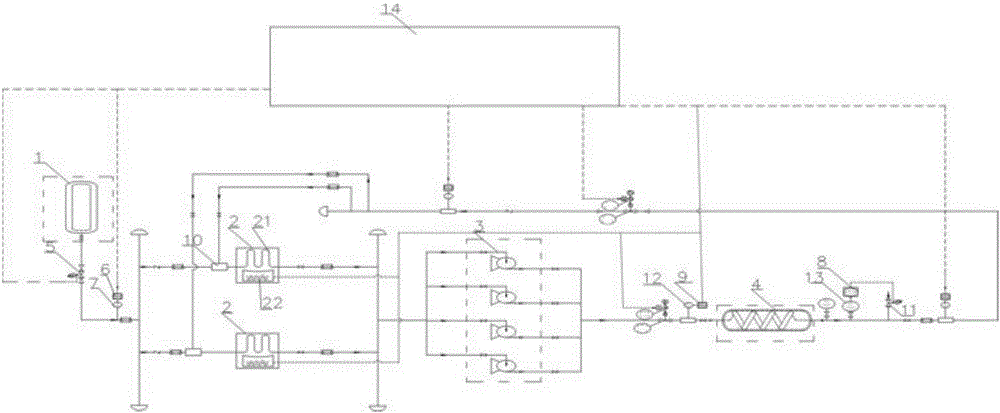

[0036] like figure 1 As shown, a high and low temperature cycle control system includes a refrigeration medium source 1, a flow regulating valve 5, a temperature control device 2, a device to be tested 4, a fan 3 and a control unit 14;

[0037] Refrigeration medium source 1, flow regulating valve 5, temperature control device 2, fan 3, and equipment to be tested 4 are connected in series in sequence; refrigeration medium source 1 is used to provide refrigeration medium so that equipment to be tested 4 can realize temperature changes; temperature control device 2 is equipped with The heating unit 22 and the conveying unit 21 for conveying the refrigerating medium, the heating unit 22 is used for heating the conveying unit 21 and then heating the refrigerating medium, the input end of the conveying unit 21 is connected with the flow regulating valve 5, the output end of the conveying unit 21 is connected with the The input end of the equipment to be tested 4 is connected, and th...

Embodiment 2

[0053] A high and low temperature rapid control method, using the high and low temperature cycle control system as described above, when cooling, the control unit 14 adjusts the opening of the flow regulating valve 5 and closes the heating unit 22, and the cooling medium in the cooling medium source 1 flows into the The delivery unit 21 of the temperature control device 2 flows into the equipment to be tested 4 to cool down the equipment to be tested 4, and the refrigerant that undergoes heat exchange in the equipment to be tested 4 is circulated from the equipment to be tested 4 to the temperature control device 2 each time, and again Cool the equipment 4 to be tested; heat up after cooling down, the control unit 14 adjusts the flow regulating valve 5 to close and turn on the heating unit 22, an internal circulation is formed between the temperature control device 2, the fan 3 and the equipment to be tested 4, and stays in the internal circulation pipe The cooling medium in th...

Embodiment 3

[0055] A constant temperature control method, when the set temperature of the first or second temperature transmitter is lower than or the ambient temperature, the opening degree of the flow regulating valve 5 and the heating power of the heating unit 22 are interlocked controlled by the control unit 14, so that the first or second temperature transmitter The temperature of the second temperature transmitter is constant within the range of ±0.5°C of the set temperature, thereby ensuring that the temperature accuracy at this point is controlled within the range of ±1°C. The specific embodiments described above have further described the purpose, technical solutions and beneficial effects of the present invention in detail. It should be understood that the above descriptions are only specific embodiments of the present invention and are not intended to limit the scope of the present invention. Protection scope, within the spirit and principles of the present invention, any modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com