Flour mill

The technology of a pulverizer and a powder outlet, which is applied in the field of household equipment, can solve the problems of easy damage and difficult replacement of the pulverizing structure, and achieve the effect of simple adjustment and realization of the thickness of the powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

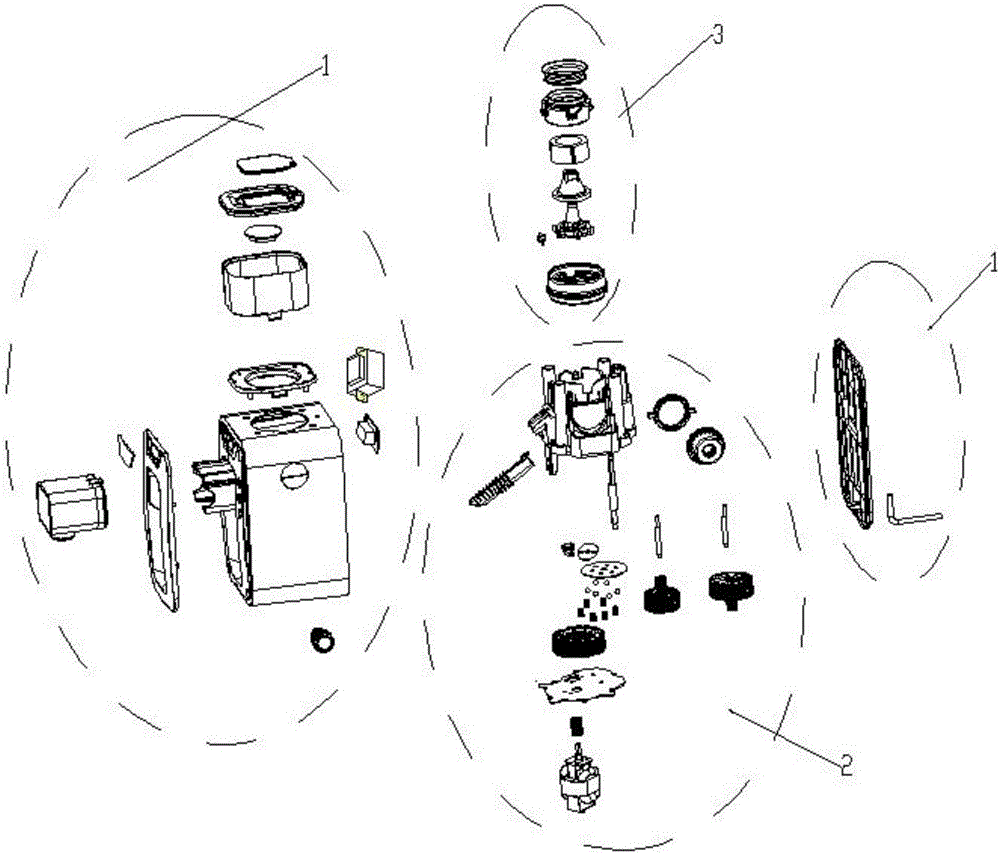

[0025] figure 1 It is a schematic diagram of the explosive structure of the pulverizer provided in Embodiment 1 of the present invention;

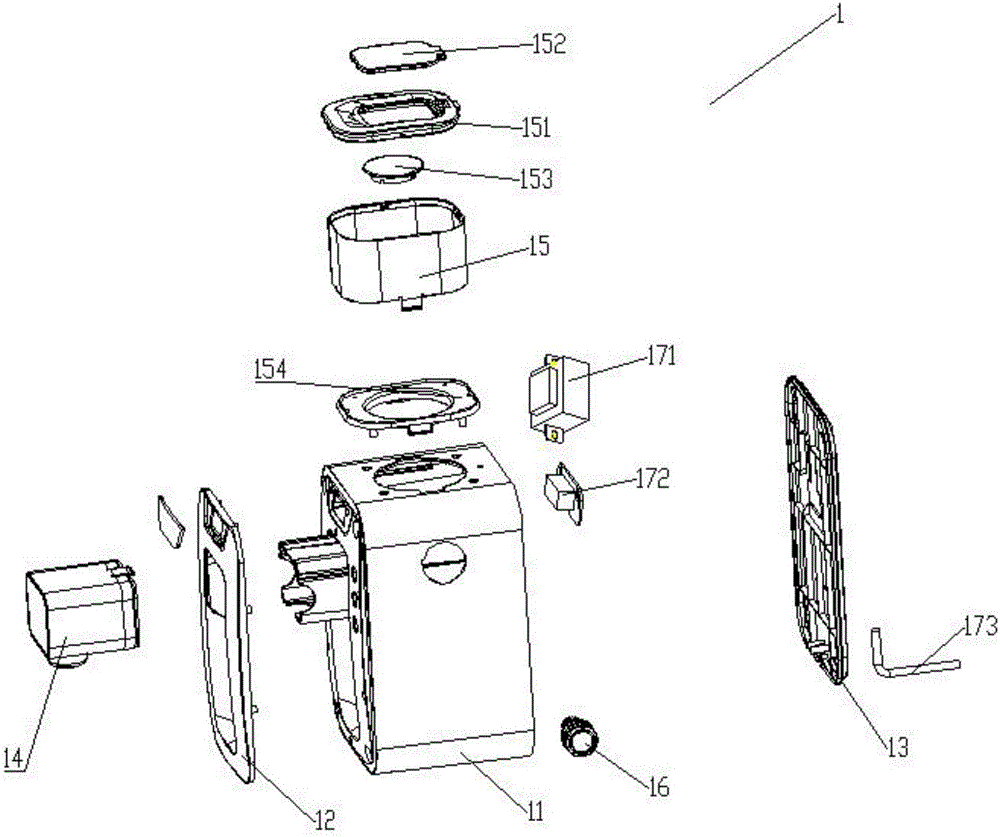

[0026] figure 2 It is a schematic diagram of the explosion structure of the shell assembly of the pulverizer provided in Embodiment 1 of the present invention;

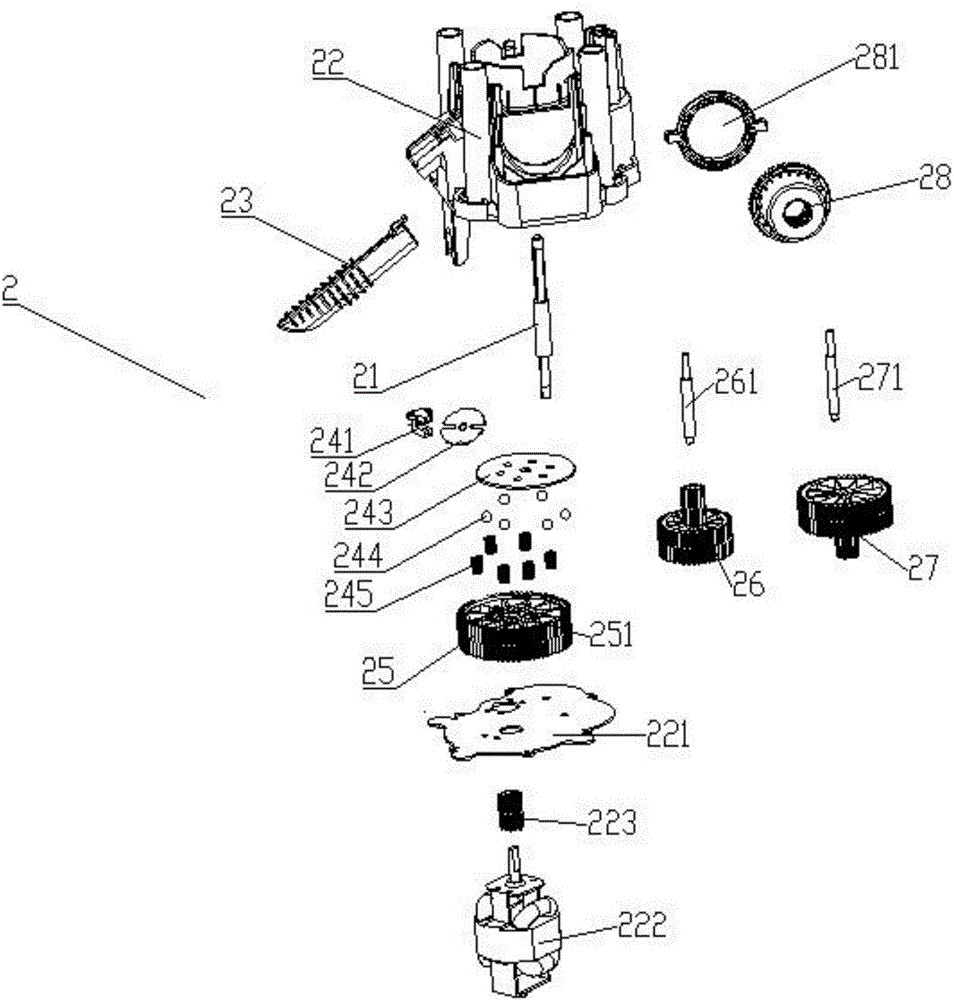

[0027] image 3 It is a schematic diagram of the explosion structure of the reduction box mechanism of the pulverizer provided in Embodiment 1 of the present invention;

[0028] Figure 4 It is a schematic diagram of the explosion structure of the cutter head mechanism of the pulverizer provided in Embodiment 1 of the present invention;

[0029] Figure 5 It is a front view sectional structural schematic diagram of the pulverizer provided in Embodiment 1 of the present invention;

[0030] Image 6 It is a side view cross-sectional structural schematic diagram of the pulverizer provided by Embodiment 1 of the present invention.

[0031] Such as Figure 1~6 As shown, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com