Double automatic feeding device of abrasive belt polishing machine and abrasive belt polishing machine using the device

A feeding device and abrasive belt polishing technology, applied in abrasive belt grinders, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of inaccurate robot positioning, low positioning accuracy, and high labor costs, and improve processing Accuracy and productivity, reducing refueling downtime and increasing robot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

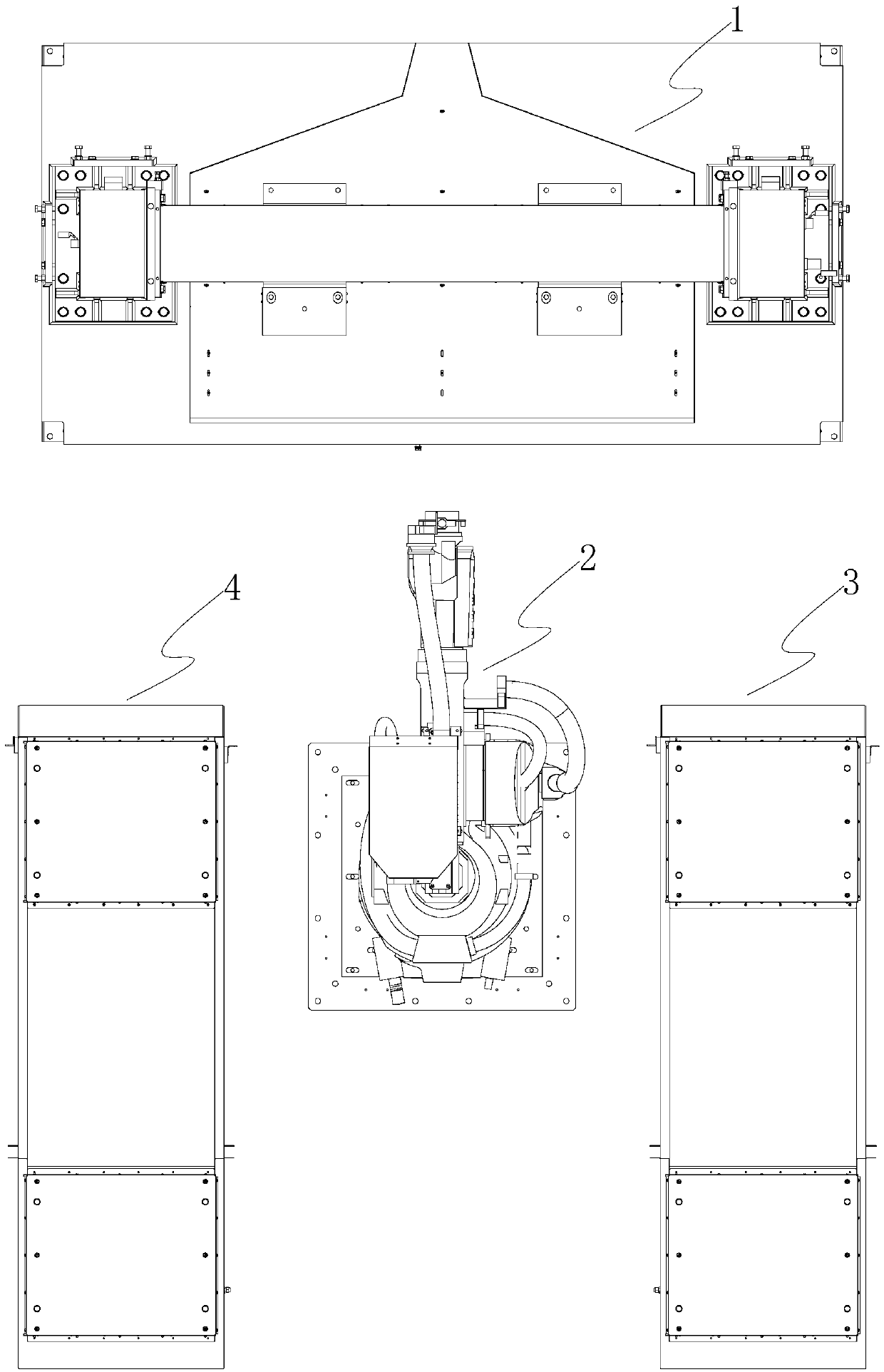

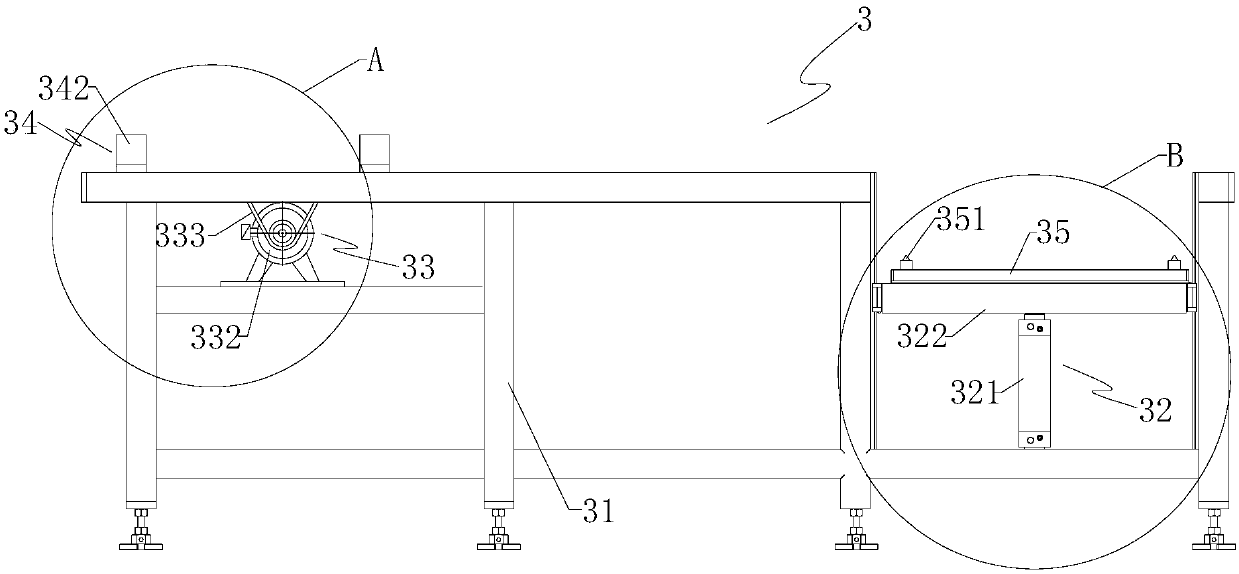

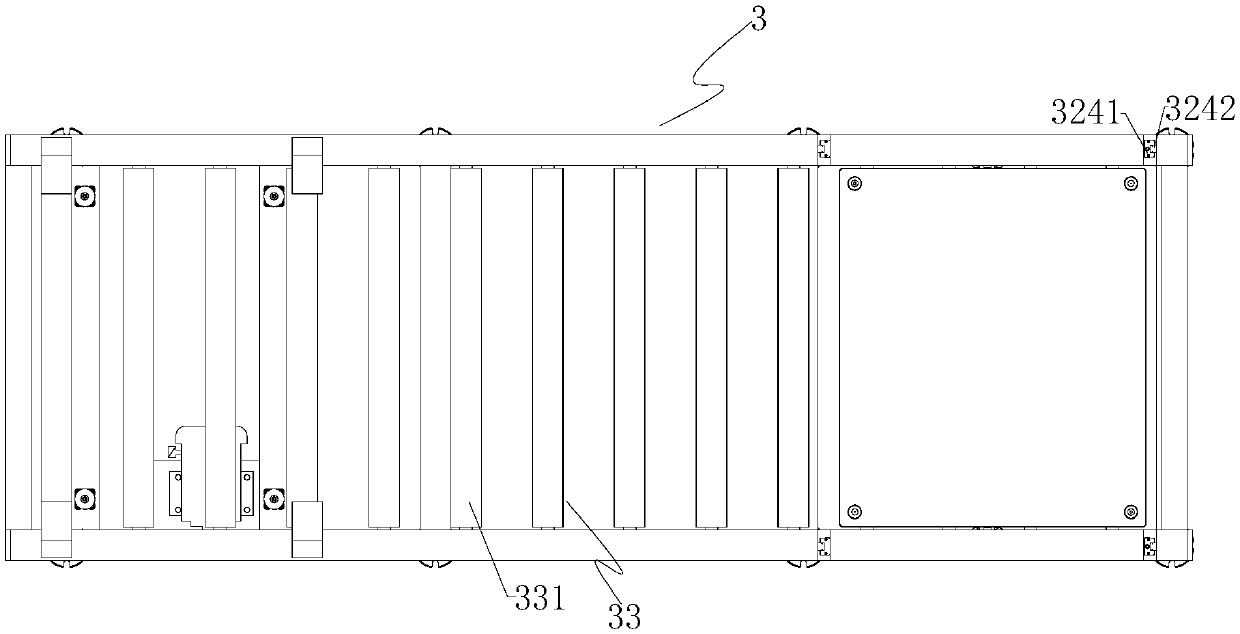

[0024] Such as Figures 1 to 5 As shown, the abrasive belt polishing machine of the present invention includes an abrasive belt polishing machine 1 and a double automatic feeding device, and the double automatic feeding device includes a robot 2 and two feeding devices 3 with the same structure symmetrically arranged around the robot. , 4. Since the structures of the two feeding devices are the same, the specific structure will be described below taking the feeding device 3 as an example: the feeding device 3 includes a frame 31, a lifting type feeding assembly 32 and a horizontal feeding assembly 33 positioned on the frame Pushing and positioning assembly 34, and the positioning tray 35 conveyed between the above-mentioned components.

[0025] The above-mentioned positioning tray 35 has a square structure, and positioning tapered convex pins 351 are respectively arranged at four corner positions on it.

[0026] The above-mentioned pushing and positioning assembly 34 is arran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap