Pin unlocking device used for separating reinforcing mesh cage from steel chisels

A technology of unlocking device and steel mesh, used in ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of poor unlocking process stability, poor stability, and low accuracy, and achieve convenient operation, accurate positioning, and positioning. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

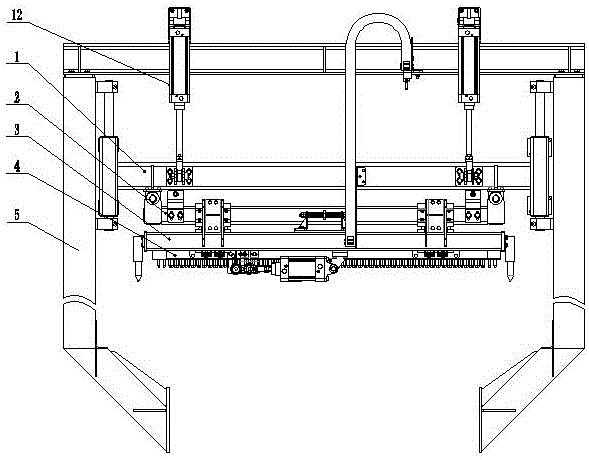

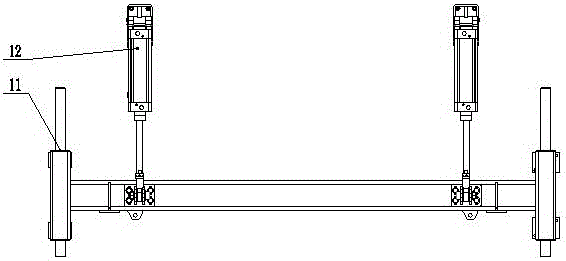

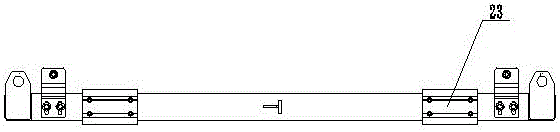

[0021] As shown in the figure, a needle unlocking device for separating a steel mesh cage and a steel drill includes a support frame 5 , a lifting frame 1 , a horizontal support frame 2 , an unlocking frame 3 and an unlocking needle frame 4 . The support frame 5 adopts a door-shaped frame structure, and the lifting frame 1 has a crossbeam, which is slidably arranged on two vertical guide columns arranged on both sides of the support frame 5 through the sliding assembly 11 provided at both ends of the crossbeam itself. The beam is provided with a first driving device 12, the first driving device 12 adopts a lifting cylinder or an oil cylinder, the number is set to two, the telescopic ends of the two lifting cylinders are connected with the beam of the lifting frame 1, and then the lifting frame 1 can be driven along the two guides. The column moves up and down in the vertical direction. Proximity sensor switches are installed on the two lifting cylinders to precisely control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com