Intelligent carton box packaging machine

A packaging machine, carton technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of difficult to accurately control the air pump, uneven force, low molding efficiency, etc., to reduce manufacturing and use costs, simple mechanism, improve The effect of packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

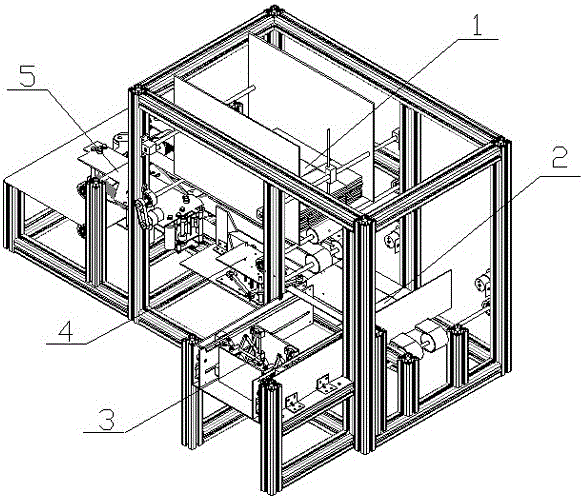

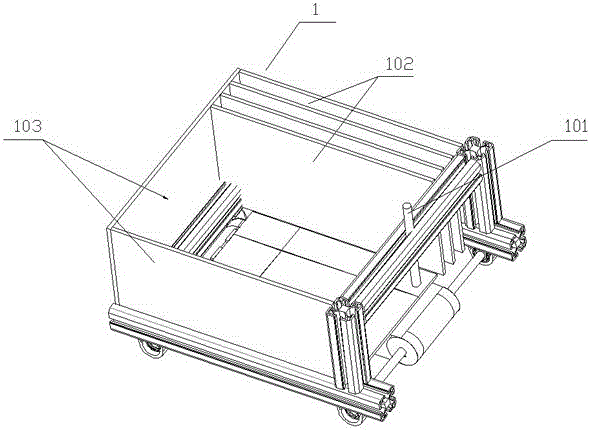

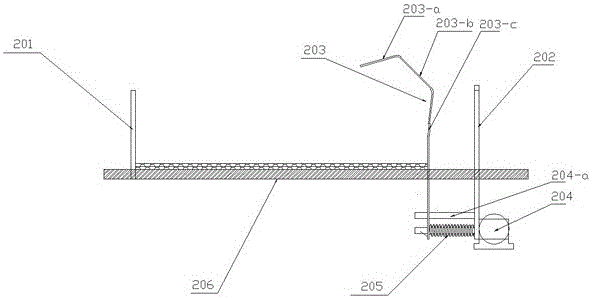

[0032] As shown in the figure, an intelligent carton sealing machine includes a carton picking mechanism 1, a carton board three-dimensional forming mechanism 2, an article pushing mechanism 3, a carton door closing mechanism 4, a tape sealing mechanism 5 and a control system.

[0033]The carton selection mechanism 1 selects the carton board and sends it to the carton board three-dimensional forming mechanism 2. The carton board three-dimensional forming mechanism 2 three-dimensionally shapes the carton board into a square carton 6 with a cavity inside. The carton 6 includes two open boxes. Door, each box door has two first box boards in the length direction and two second box boards in the width direction, the item pushing mechanism 3 pushes the items to be packaged into the cavity of the carton 6, and the carton door closing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com