Oil separation and slag removal device

An oil scraping device and oil separation technology, which is applied in the directions of grease/oily substance/float removal device, water/sludge/sewage treatment, liquid separation, etc. Deal with problems such as work difficulties, and achieve the effects of improving oil drainage, thorough oil-water separation, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

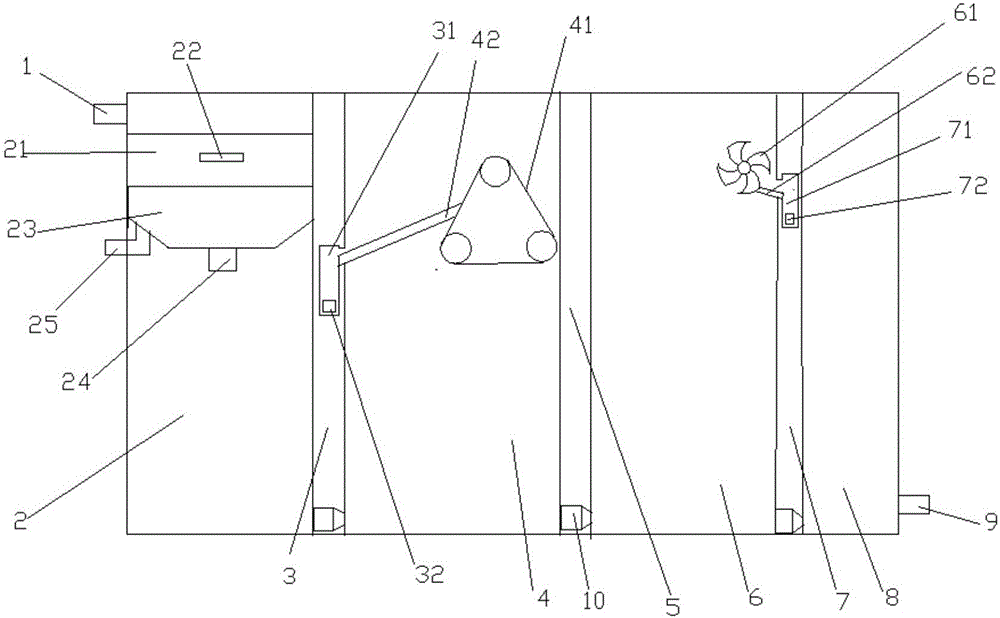

[0019] An oil-separating and slag-removing device, including a box body, the box body is a water inlet 1, a slag-removing area 2, a first partition 3, a first oil-scraping area 4, a second partition 5, The second oil scraping area 6, the third partition 7, the transition area 8 and the water outlet 9,

[0020] The top of the first dividing plate 3, the second dividing plate 5 and the third dividing plate 7 reach the top of the box body, and the bottom end is in close contact with the bottom wall of the box body. The first dividing plate 3, the second dividing plate The bottom ends of the dividing plate 5 and the third dividing plate 7 are all provided with water openings connecting two adjacent areas, and the water openings are provided with water flow deceleration devices 10, and the first dividing plate 3 is provided with a first Oil collecting tank 31, and open towards the first oil scraping area 4 on the upper part of the first oil collecting tank 31, the first oil dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com