Roll-type graphene continuous growth equipment

A graphene, roll-type technology, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problem of not considering the sealing device to affect the uniform distribution of gas in the process chamber, affecting the graphene growth efficiency, and difficult. Realize problems such as controllable preparation of high-quality graphene, and achieve the effect of improving preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

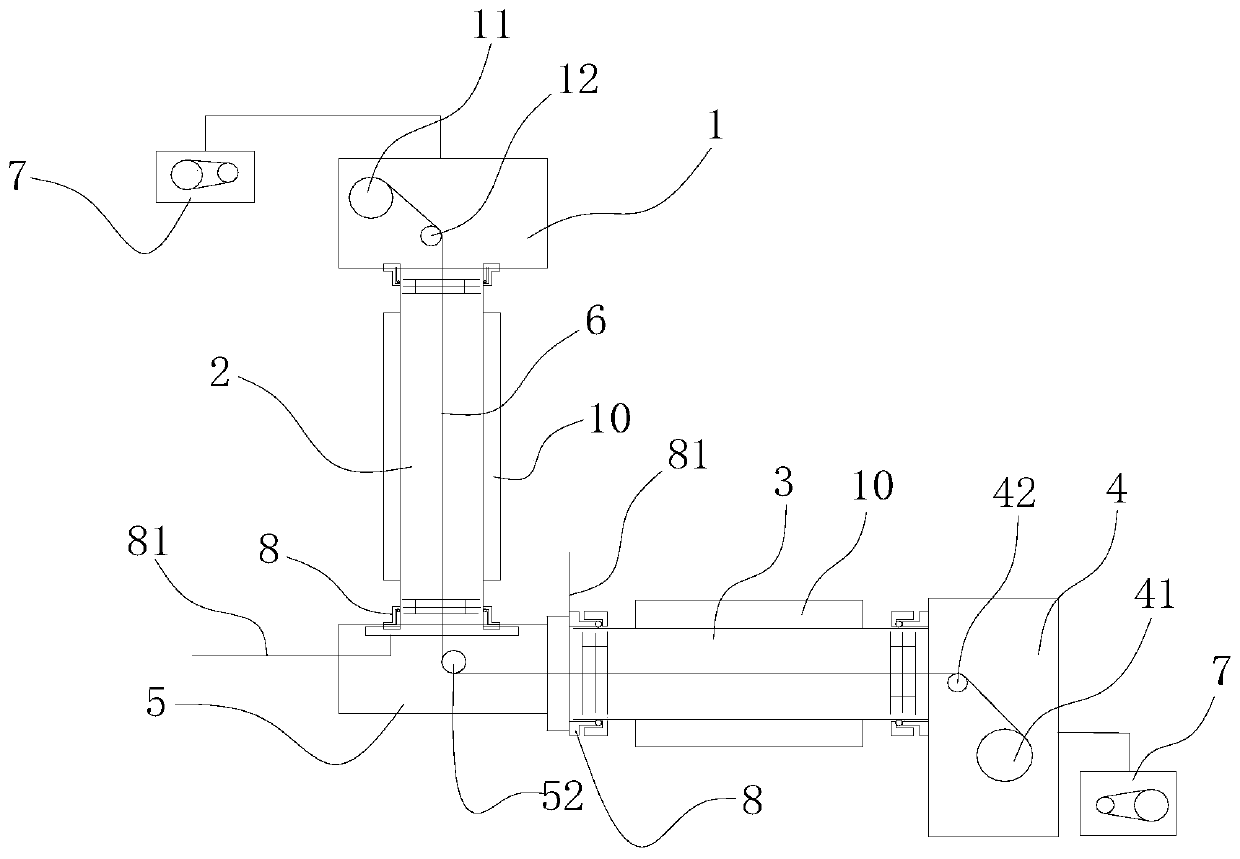

[0046] like figure 1 , 4 , 5 and 6, the roll-type graphene continuous growth equipment includes a discharge cooling chamber 1 and a receiving cooling chamber 4; a graphene growth substrate discharge roller 11 and a discharge cooling chamber 1 are arranged in the discharge cooling chamber 1. Material cooling zone guide roller 12, described receiving material cooling chamber 4 is provided with long graphene base material receiving roller 41 and receiving material cooling chamber guide roller 42; Described discharging cooling chamber 1 is provided with a vacuum pump 7, described The receiving cooling chamber 4 is provided with a vacuum pump 7 .

[0047] The roll-type graphene continuous growth equipment also includes a first high-temperature process chamber 2, a second high-temperature process chamber 3 and a transition chamber 5; two ends of the first high-temperature process chamber 2 and two ends of the second high-temperature process chamber 3 Each end is provided with a un...

Embodiment 2

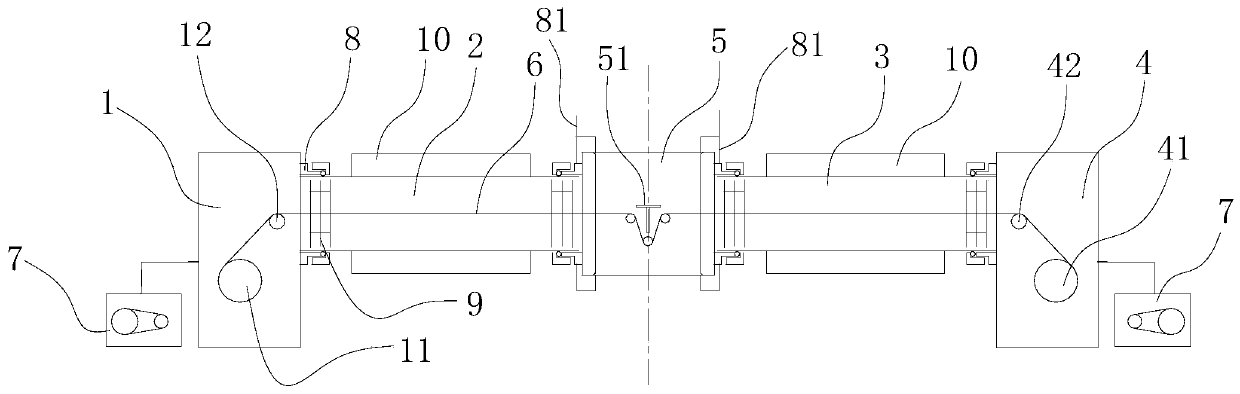

[0053] like figure 2 , 4 , 5 and 6, the roll-type graphene continuous growth equipment includes a discharge cooling chamber 1 and a receiving cooling chamber 4; a graphene growth substrate discharge roller 11 and a discharge cooling chamber 1 are arranged in the discharge cooling chamber 1. Material cooling zone guide roller 12, described receiving material cooling chamber 4 is provided with long graphene base material receiving roller 41 and receiving material cooling chamber guide roller 42; Described discharging cooling chamber 1 is provided with a vacuum pump 7, described The receiving cooling chamber 4 is provided with a vacuum pump 7 .

[0054] The roll-type graphene continuous growth equipment also includes a first high-temperature process chamber 2, a second high-temperature process chamber 3 and a transition chamber 5; two ends of the first high-temperature process chamber 2 and two ends of the second high-temperature process chamber 3 Each end is provided with a u...

Embodiment 3

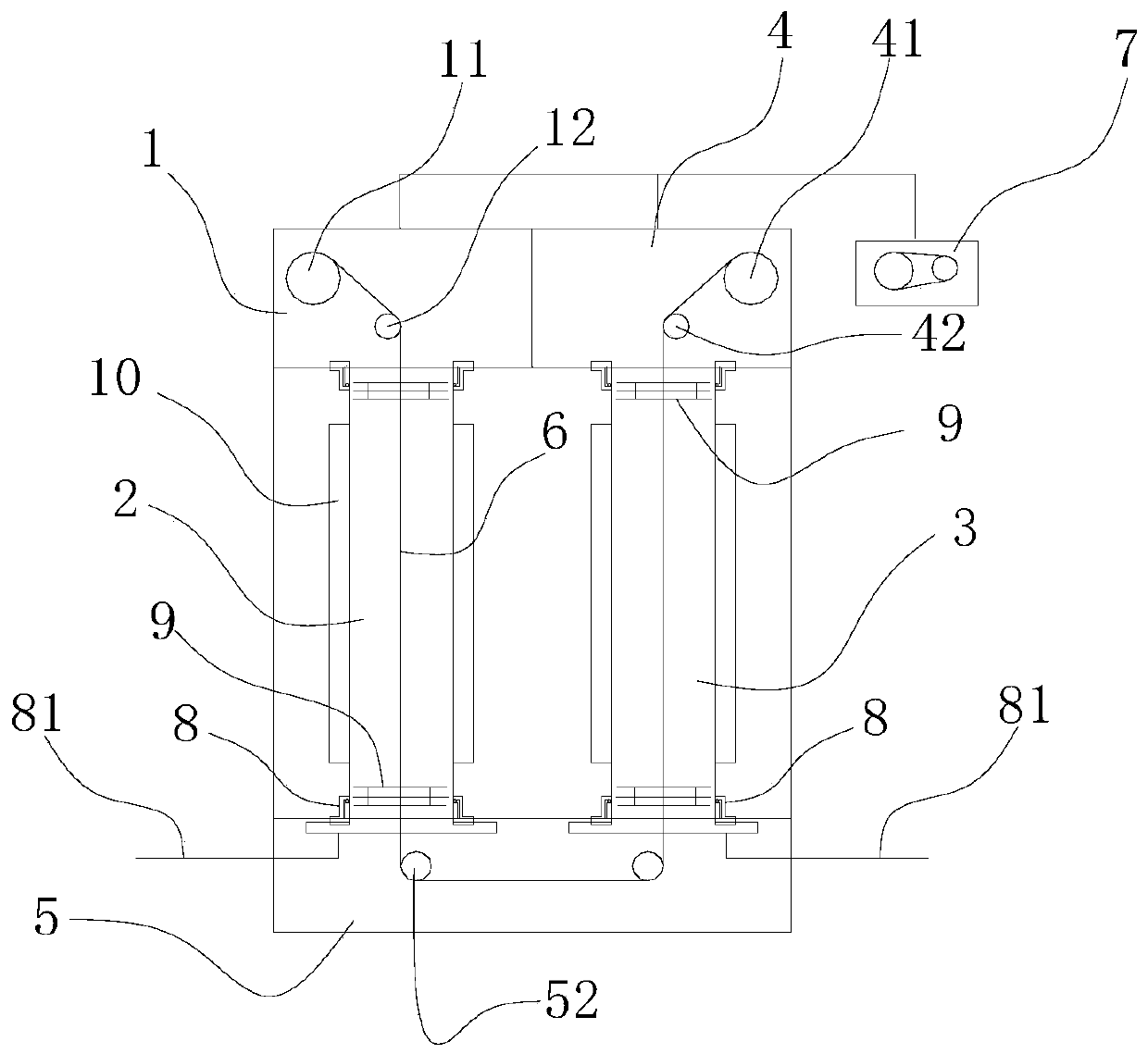

[0060] like image 3 , 4 , 5 and 6, the roll-type graphene continuous growth equipment includes a discharge cooling chamber 1 and a receiving cooling chamber 4; a graphene growth substrate discharge roller 11 and a discharge cooling chamber 1 are arranged in the discharge cooling chamber 1. Material cooling zone guide roller 12, described receiving material cooling chamber 4 is provided with long graphene base material receiving roller 41 and receiving material cooling chamber guide roller 42; Described discharging cooling chamber 1 is provided with a vacuum pump 7, described The receiving cooling chamber 4 is provided with a vacuum pump 7 .

[0061] The roll-type graphene continuous growth equipment also includes a first high-temperature process chamber 2, a second high-temperature process chamber 3 and a transition chamber 5; two ends of the first high-temperature process chamber 2 and two ends of the second high-temperature process chamber 3 Each end is provided with a un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com