Construction method for reinforcing steel structure beam or column

A construction method and technology for steel structural beams, applied in truss structures, columns, joists, etc., can solve problems such as torsional bearing capacity that does not involve steel strands, and achieve convenient positioning and connection, restraining twisting, and improving torsional resistance. The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

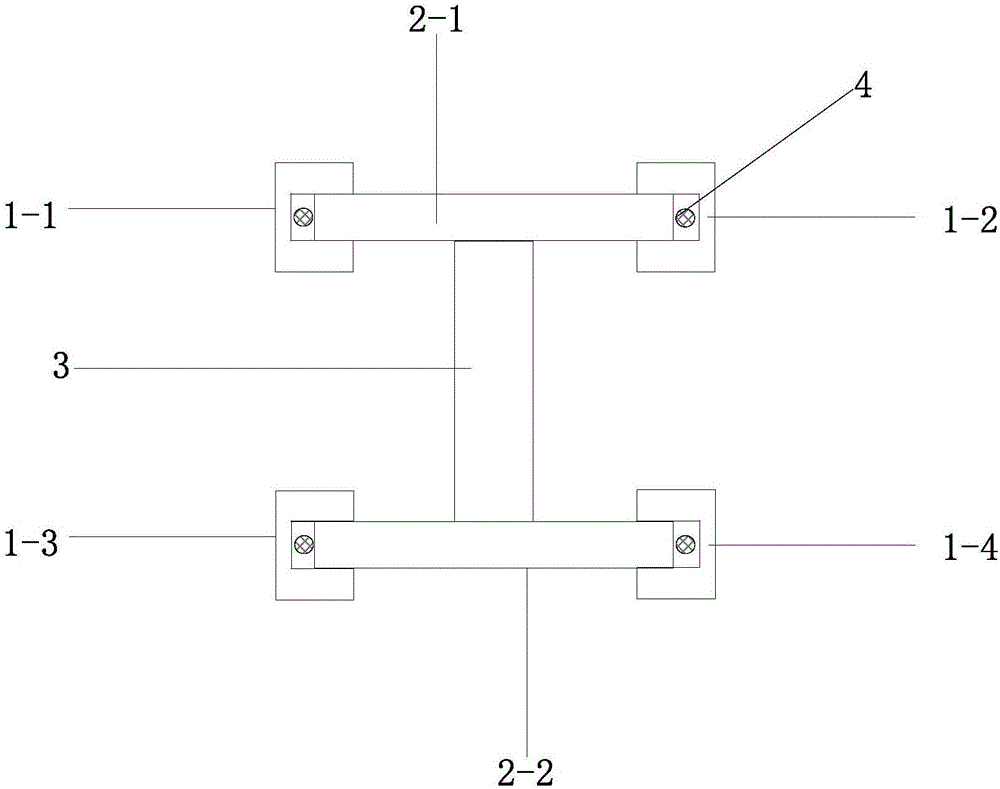

[0020] Embodiment 1: as Figure 1-2 As shown, a construction method for strengthening steel structure side beams, the beam or column adopts basic section steel, and its construction steps are as follows:

[0021] First, prepare components: basic section steel, 4 U-shaped channel steels 1-1, 1-2, 1-3, 1-4; -2. Composed of web 3, the upper flange 2-1 and the lower flange 2-2 have the same structure;

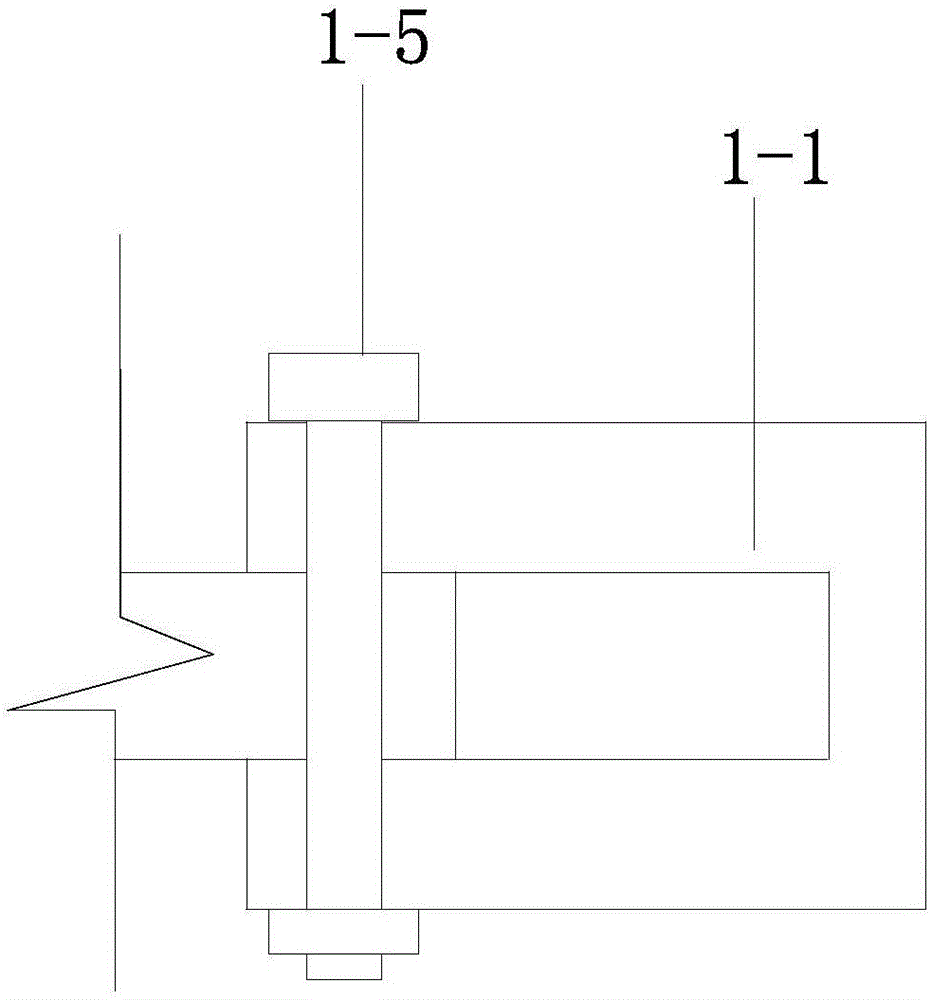

[0022] Second, insert 4 U-shaped channel steels into the four corners of the upper and lower flanges of the foundation steel. Bolt holes are preset between the U-shaped channel steel and the flanges of the foundation steel. The U-shaped channel steel and the foundation The bolt holes of the flange of the section steel are aligned, and the two are fixed by the bolt and nut assembly 1-5; there is a channel 4 through which prestressed tendons are formed between the U-shaped channel steel and the flange;

[0023] Thirdly, the prestressing tendons are passed through the 4-corner tunne...

Embodiment 2

[0024] Embodiment 2: A construction method for strengthening a side column of a steel structure. The difference from Embodiment 1 is that: the base section steel is a column; prestressed steel strands are anchored at the upper and lower ends of the column.

Embodiment 3

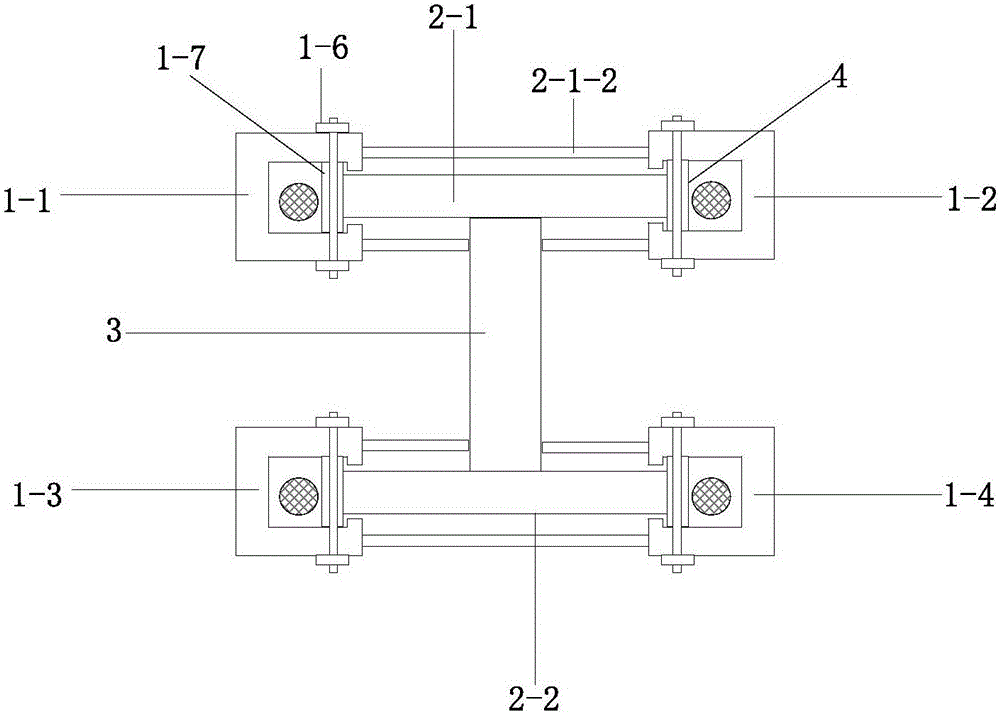

[0025] Embodiment 3: as image 3 Shown, a kind of construction method of reinforcing steel structure beam or column, described beam or column adopts foundation section steel, and its construction steps are as follows:

[0026] First, prepare components: basic section steel, 4 U-shaped channel steels 1-1, 1-2, 1-3, 1-4; -2. Composed of web 3, the upper flange 2-1 and the lower flange 2-2 have the same structure; vertical steel pipes 1-7 are respectively welded on the left and right sides of the upper flange and the lower flange of the basic section steel, and the vertical The flange protrudes toward both ends of the steel pipe, the height of the vertical steel pipe is greater than the thickness of the flange, and the vertical steel pipe is hollow; the distance between the vertical steel pipes is 15-50cm;

[0027] Second, insert 4 U-shaped channel steels into the four corners of the upper and lower flanges of the foundation steel. Bolt holes are preset between the U-shaped chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com