A reciprocating plunger pump

A plunger pump, reciprocating technology, applied in the field of reciprocating plunger pump, can solve the problems of low pump efficiency, reduce the viscosity reduction rate of polymers, etc., and achieve the effects of low suction performance, reduced lag angle, and large flow loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

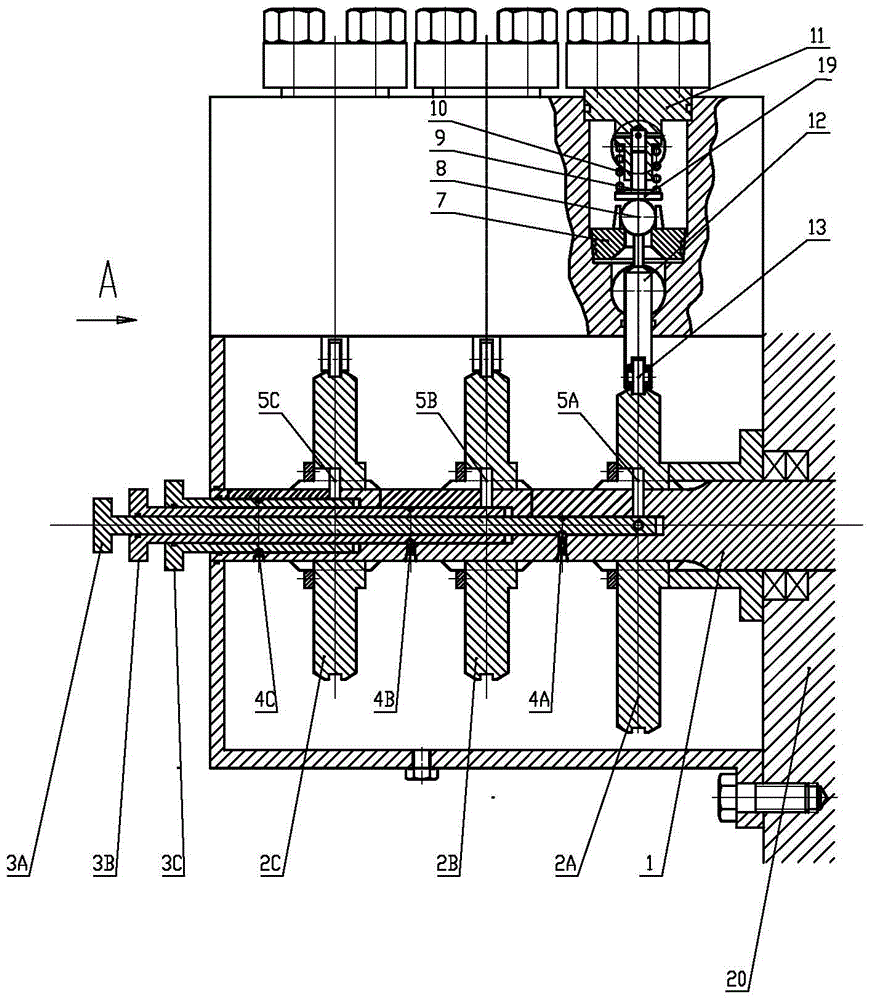

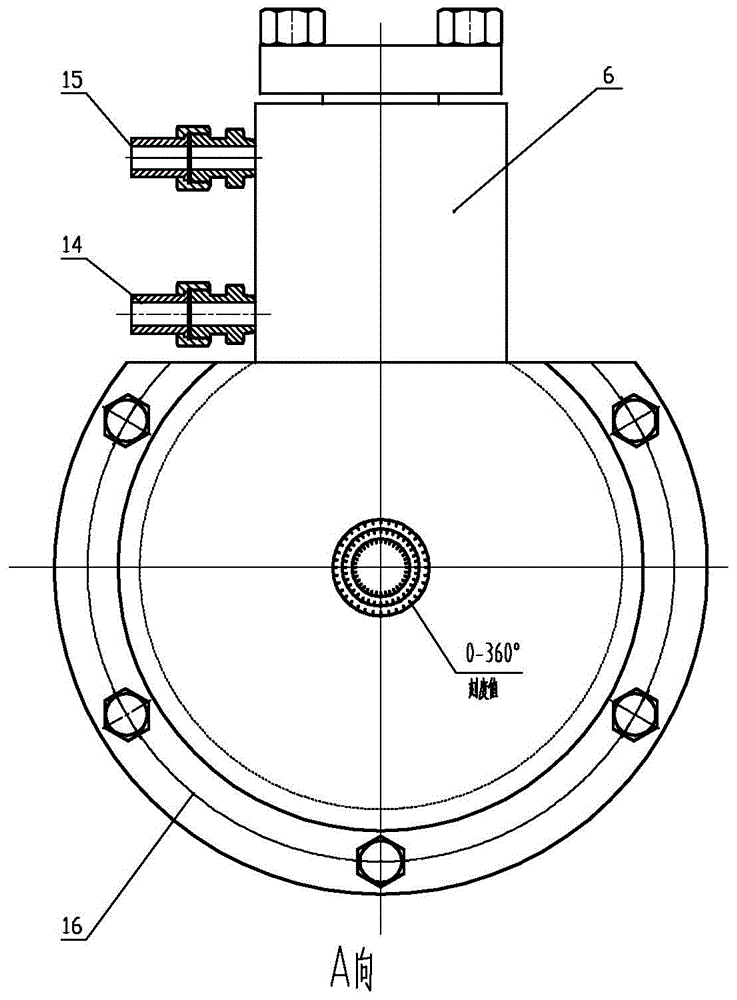

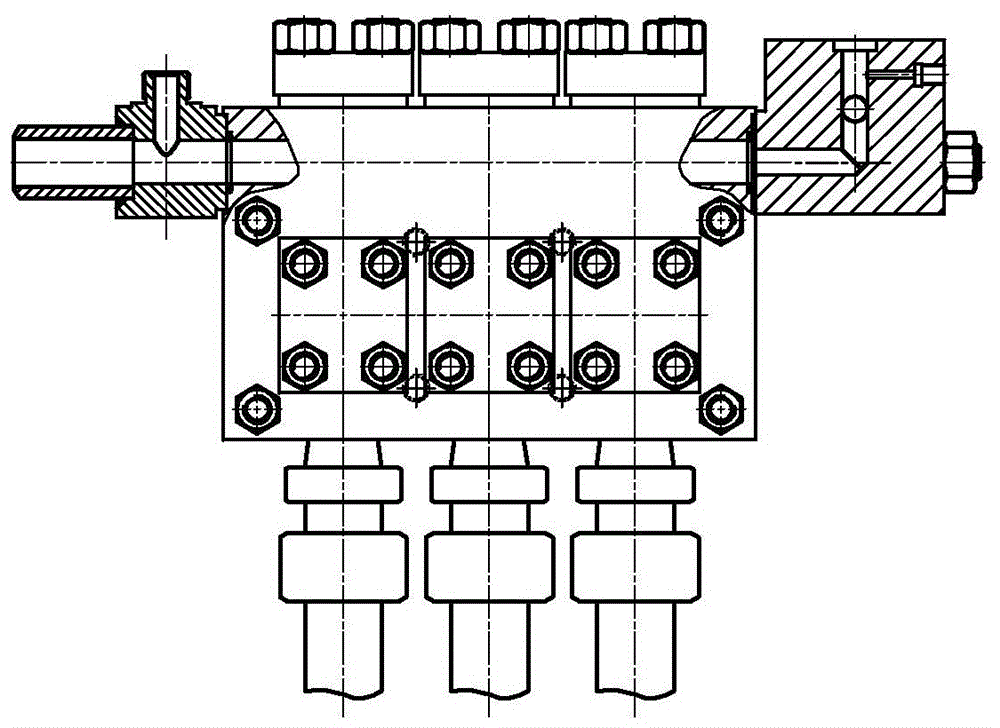

[0025] Take the reciprocating plunger pump of three-cylinder structure as an example below to describe the structure of the present invention in detail, as image 3 and Figure 4 The three-cylinder reciprocating plunger pump shown includes a pump body 17, three sets of discharge valve assemblies 18 are arranged inside the pump body 17, and three sets of liquid inlet valve assemblies are arranged outside the pump body 17, and the liquid inlet valve assemblies include liquid inlet valve assemblies and inlet valve drive mechanism. Wherein the liquid inlet valve includes a valve seat 7, and the valve seat 7 is provided with: a spherical valve core 8, a stopper 19 offset against the spherical valve core 8, a guide rod 9 is arranged above the stopper 19, and the guide rod 9 is covered with a liquid inlet Spring 10, limit plug 11, the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com