Double-row nozzle structure for cold air prerotation

A cold air pre-rotation and nozzle technology, which is applied in the cooling of the engine, the cooling of the turbine/propulsion device, the engine components, etc., can solve the problems of the heat exchange difference at the low radius of the turntable, and achieve the increase of the total area, the total flow rate, The effect of temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

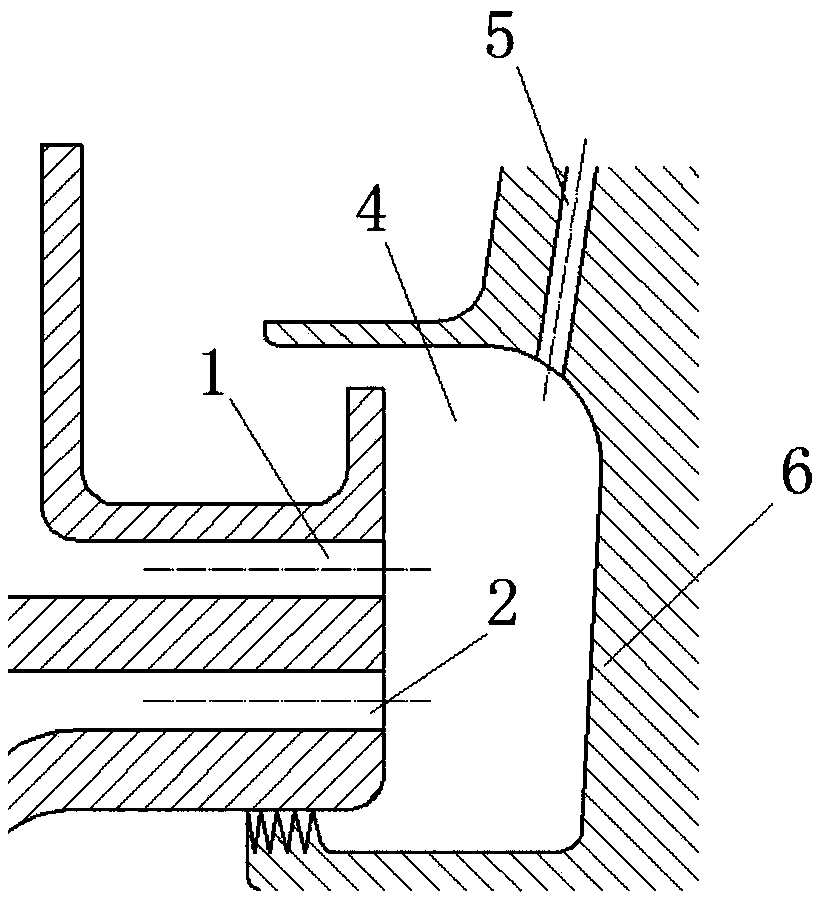

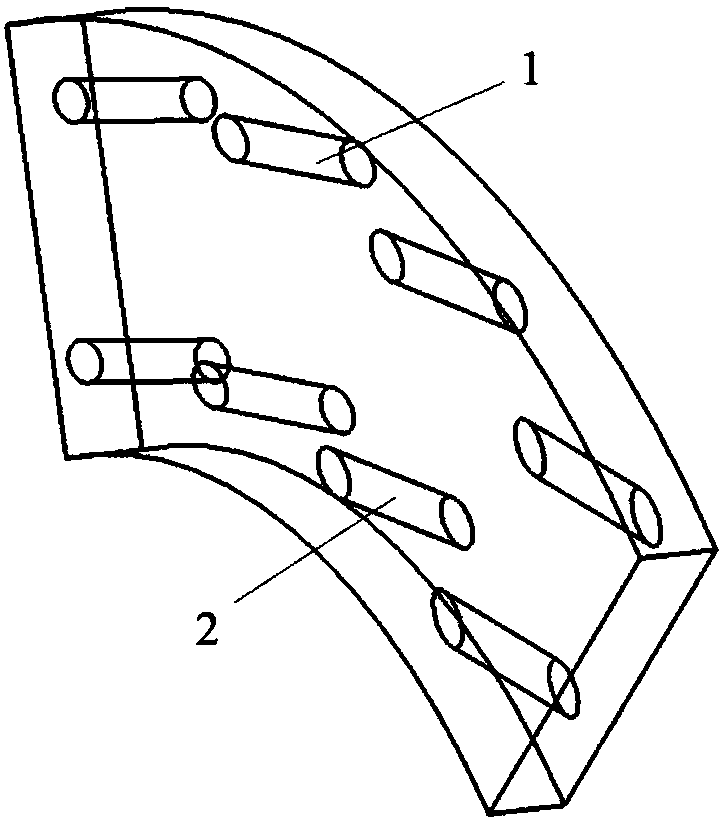

[0026] This embodiment is a double-row pre-swirl nozzle used in a pre-swirl system, including a circle of high-radius nozzles 1 at a high-radius position and a circle of low-radius nozzles 2 at a low-radius position. The air flows from the air intake cavity into the rotating disc cavity 4 through two rows of nozzles at high and low radius positions respectively, which can improve the heat exchange effect at the low radius position of the rotating disc 6 .

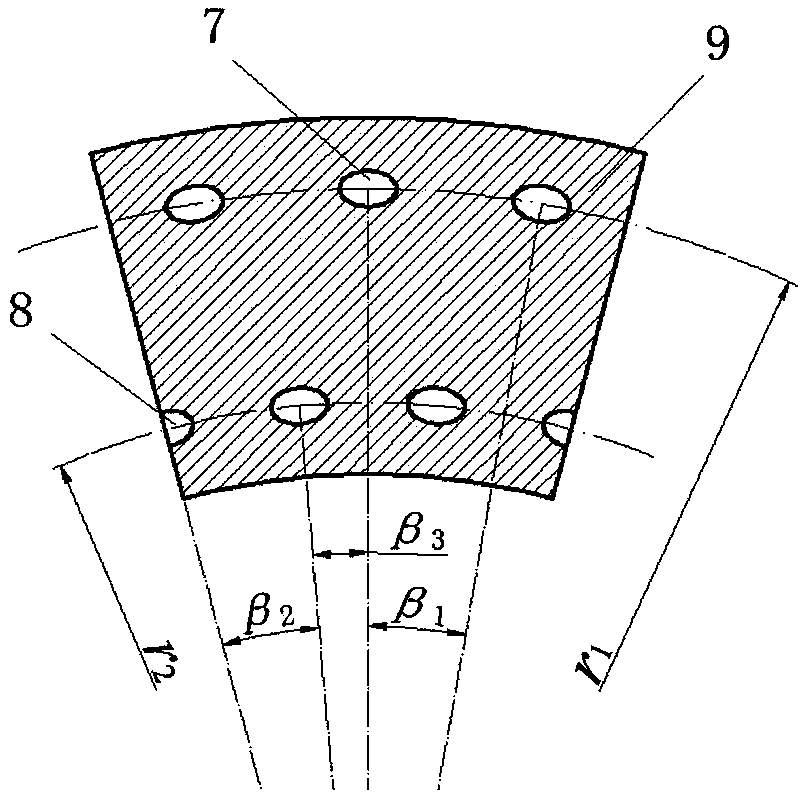

[0027] The structural parameters of the double-row nozzles in this embodiment: r 1 The radius of rotation of the high radius nozzle, r 2 Rotation radius of low radius nozzle, β 1 Angle between every two high radius nozzles, β 2 Angle between every two low radius nozzles, β 3 The circumferential angle between a high-radius nozzle and a low-radius nozzle, θ pre-swivel angle.

[0028] The high-radius nozzles and low-radius nozzles are evenly distributed along the circumferential direction. The angle θ between the nozzle an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com