Magnetomotive flexible circulation heat dissipation system and heat dissipation device

A technology of circulating heat dissipation and heat dissipation devices, applied in projection devices, optics, instruments, etc., can solve problems such as inability to effectively improve heat dissipation capacity, mechanical wear reliability, etc. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

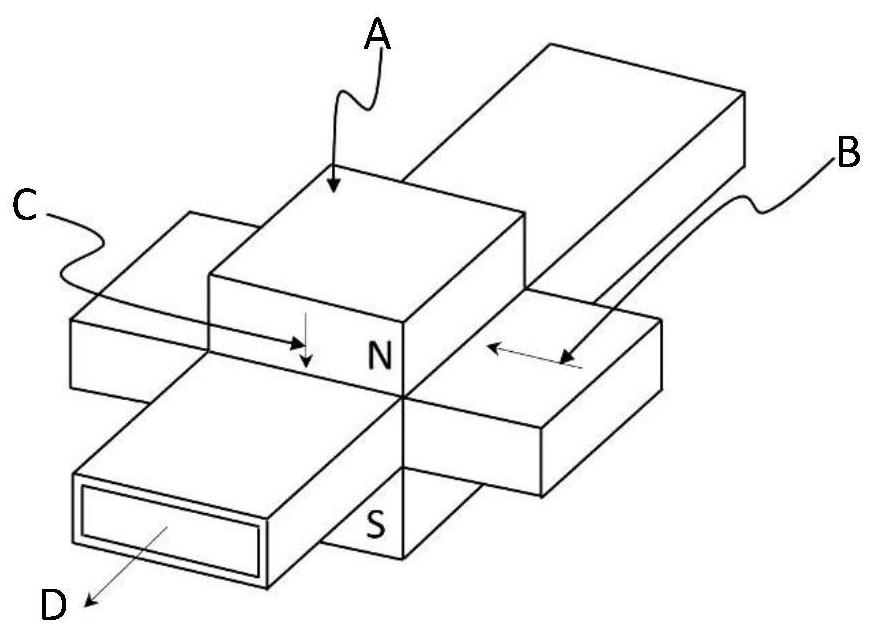

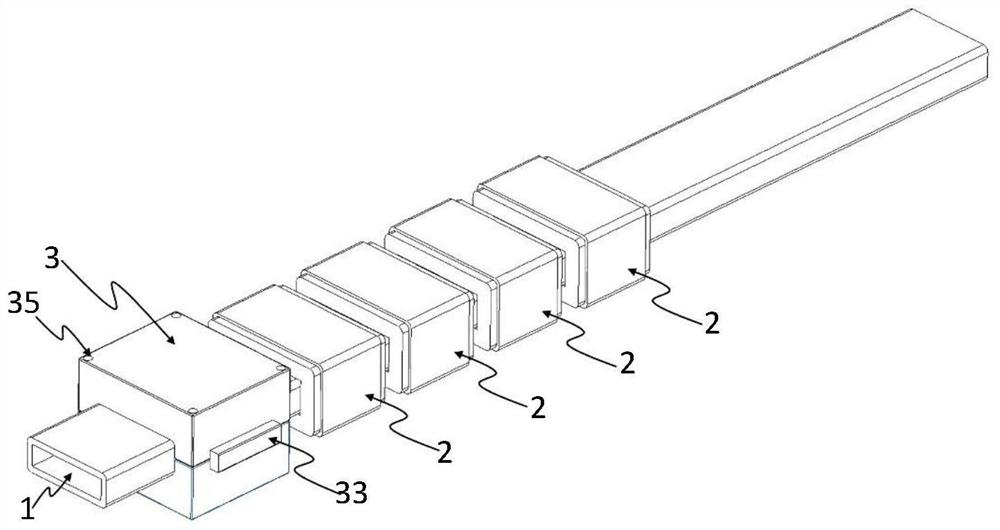

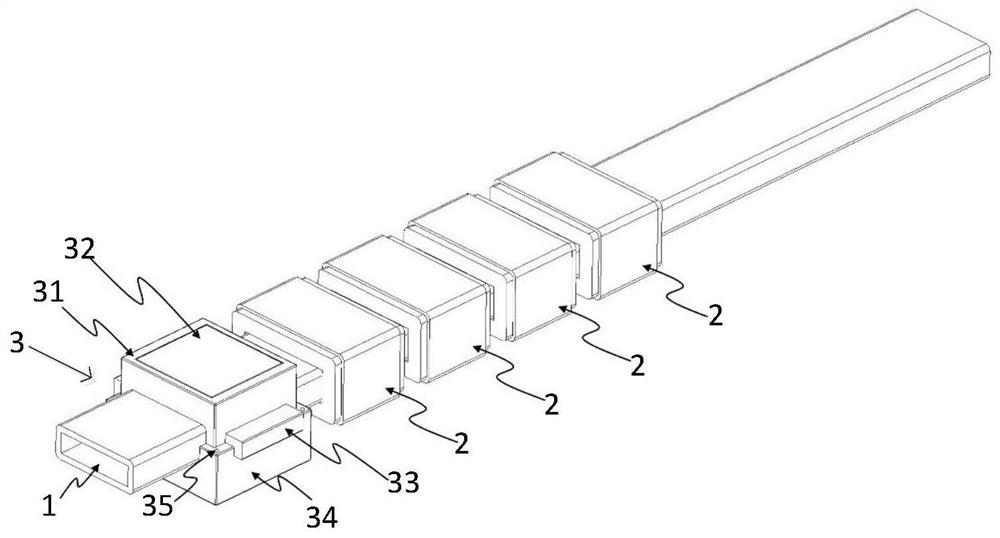

[0044] Such as figure 2 and image 3 As shown, a magnetodynamic flexible circulation heat dissipation system of this embodiment includes a fluid pipeline 1 for feeding liquid metal fluid working medium, a plurality of metal coils 2 and an electromagnetic pump 3, and a plurality of metal coils 2 are spaced apart from each other. Sleeved on the fluid pipeline 1, the electromagnetic pump 3 is installed on the fluid pipeline 1; the liquid metal fluid working medium includes liquid metal added with magnetic particles or liquid alloy added with magnetic particles.

[0045] The liquid metal or liquid alloy in this embodiment can be a liquid metal or liquid alloy with a low melting point, such as gallium or a gallium-based alloy. Use liquid metal or liquid alloy to replace deionized water, oil, and fluorocarbon organic liquid as the basic working fluid of the liquid cooling circulation system, thereby further improving the thermal conductivity of the liquid cooling circulating working...

Embodiment 2

[0059] Such as Figure 4-Figure 6 As shown, a heat dissipation device of this embodiment includes a heat source device, a cold row 5 and the heat dissipation system, the heat source device has a high-power device, and the fluid pipeline 1 passes through the high-power device and the cold row 5, and transfer the heat of the high-power device to the cold row 5.

[0060] The cold row 5 in this embodiment includes a water radiator. The use of water radiators instead of separate heat pipe radiators can maximize the use of the remaining space inside the chassis of the cooling device to increase the cooling area and improve the cooling capacity of the system. Copper can be used as the pipe material of the radiator water drain, which can resist the corrosion of liquid metal, meet the long-term reliability requirements, and has excellent thermal conductivity.

[0061] In this embodiment, the connection of the fluid pipeline and the connection of other components can adopt quick plugg...

Embodiment approach 1

[0067] Implementation mode one: if Figure 4As shown, the laser projector includes a housing 41 and an optical machine 42, a lens 43, a sound box 44, a fan 45 and a plurality of high-power devices arranged in the housing 41. Each high-power device can be a chip 4, a laser light source 46, etc. Devices, for example, the high-power device on the left is the chip 4 , and the high-power devices on the middle and right are the laser light source 46 . The normal direction of the contact surface of each high-power device heat source is the same, that is, they are all arranged horizontally, and the fluid pipeline 1 in contact with the high-power device heat source can also adopt a serpentine structure bent back and forth. The fluid pipeline 1 between adjacent high-power devices is provided with an electromagnetic pump 3 and a multi-stage metal coil 2, and a flexible bellows 61 is used for transition connection at the bend. The circulation loop can be bent in a serpentine shape and be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com