Automatic backwashing filter with large filtering area

A technology of filtering area and backwashing, which is applied in the direction of fixed filter element filter, filtering separation, filtering treatment, etc., which can solve the problems of insufficient sewage treatment capacity and small volume, so as to improve the treatment capacity, increase the filtering area, increase the The effect of the total area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

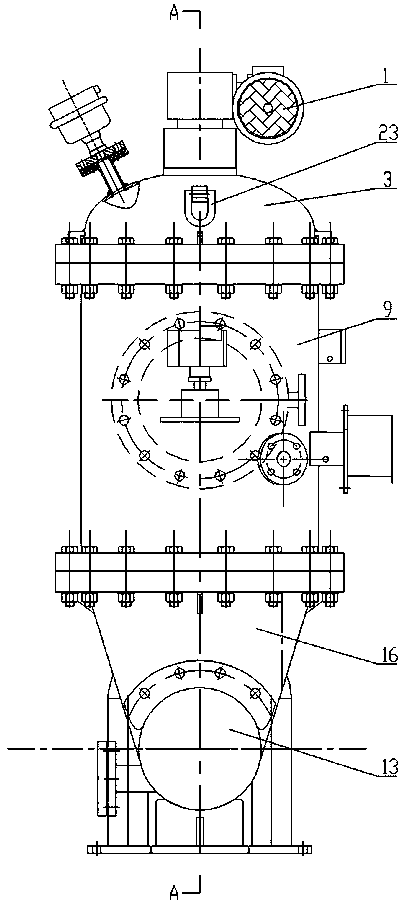

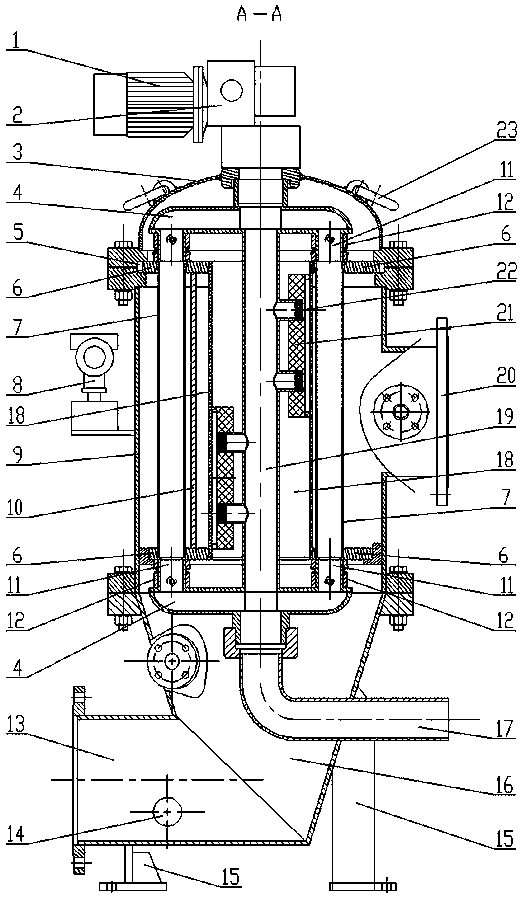

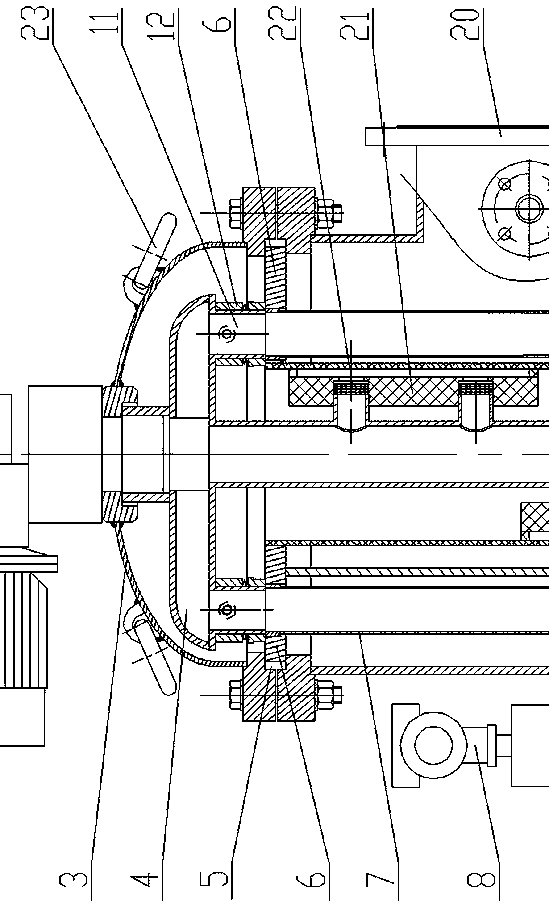

[0023] Referring to the accompanying drawings, the specific implementation is as follows:

[0024] An automatic backwash filter with a large filtering area, including a cylinder body 9, two clamping plates 6 are arranged inside the cylinder body 9, a filter cartridge 18 is fitted between the two clamping plates 6, and two clamping plates 6 There are filter cartridge water holes 24 correspondingly connected to the ends of the filter cartridge 18 on the top, a water inlet cone 16 is installed at the bottom of the cylinder body 9, a head 3 is installed on the top of the cylinder body 9, and the side wall of the cylinder body 9 is provided with There is a water outlet 20, and the water outlet 20 is located between the two clamping plates 6 so that the water flowing out through the side wall of the filter cartridge 18 is sent out from the cylinder body 9. A sewage suction pipe 19 is arranged in the filter cartridge 18, and the sewage suction pipe 19 Set coaxially with the filter ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com