Magnetic coupling

A technology of magnetic couplers and permanent magnets, which is applied in the direction of electrical components, generators/motors, etc., and can solve problems such as failure and shedding, distortion of magnetic material arrangement, and unsuitable precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

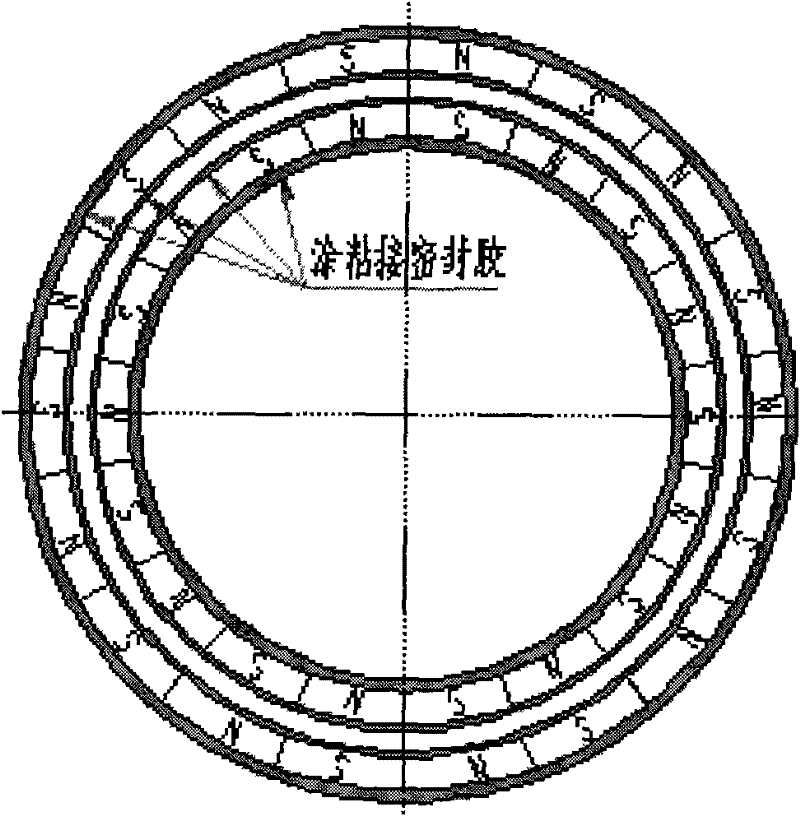

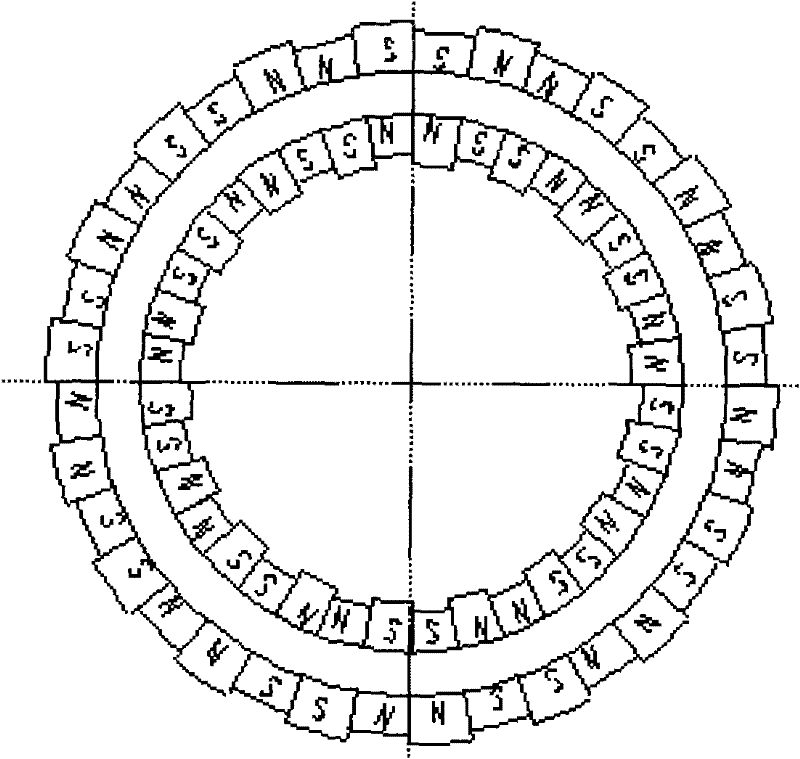

[0011] attached figure 2 For the concrete structure of an embodiment of the present invention, by figure 2 It can be seen that the N-S poles of the permanent magnets of the present invention are arranged along the axial direction of the rotor, but the outer circle of the inner rotor and the inner circle of the outer rotor of the present invention are respectively fixed with permanent magnets in a mosaic manner. In a specific implementation, the structure for the permanent magnet is processed at the inner and outer rotors by a wire cutting machine tool. In order to enable the permanent magnets to be inlaid well on the inner and outer rotors, the permanent magnets can be processed into wedge-shaped shapes with slightly different sizes according to the inlay combination.

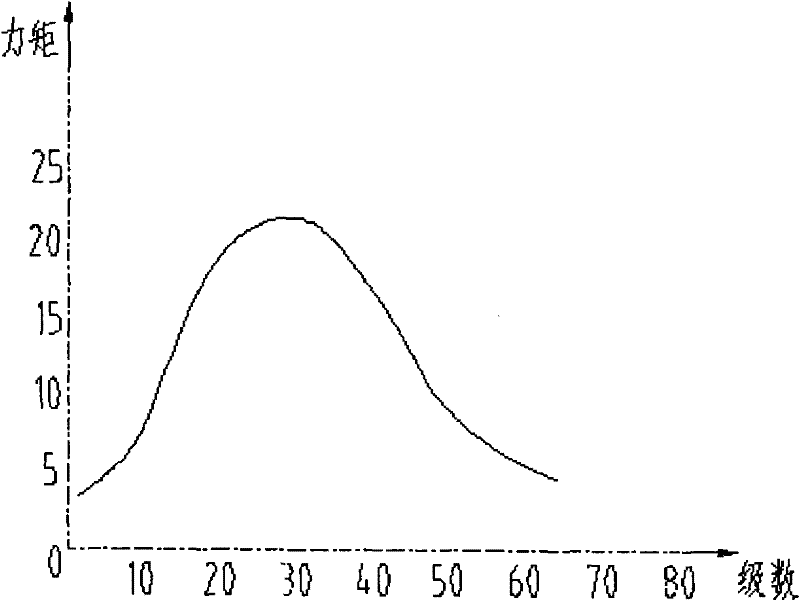

[0012] The relevant experiments of the present invention show that when the magnets are embedded, every two permanent magnets with the same polarity are grouped into one group, and the opposite polarities of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com