Device used for restraining self-excited oscillation of servo valve and capable of adjusting orifice area

A self-excited oscillation, servo valve technology, applied in the direction of fluid pressure actuation device, servo meter circuit, fluid pressure actuation system components, etc. Servo valve support and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

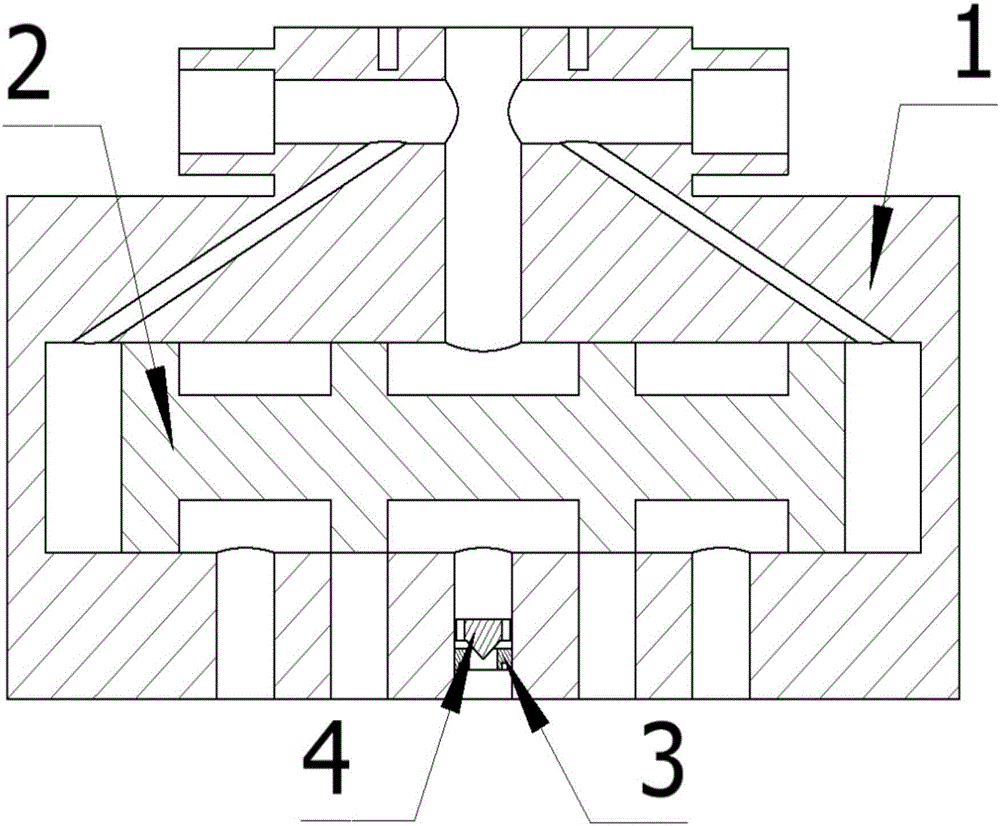

[0019] In this embodiment, a device for suppressing self-excited oscillation of a servo valve with an adjustable orifice area includes a valve seat 1, a slide valve 2 adapted to the valve seat 1, an oil return hole of the valve seat, and an oil return hole arranged on the valve seat throttling device inside;

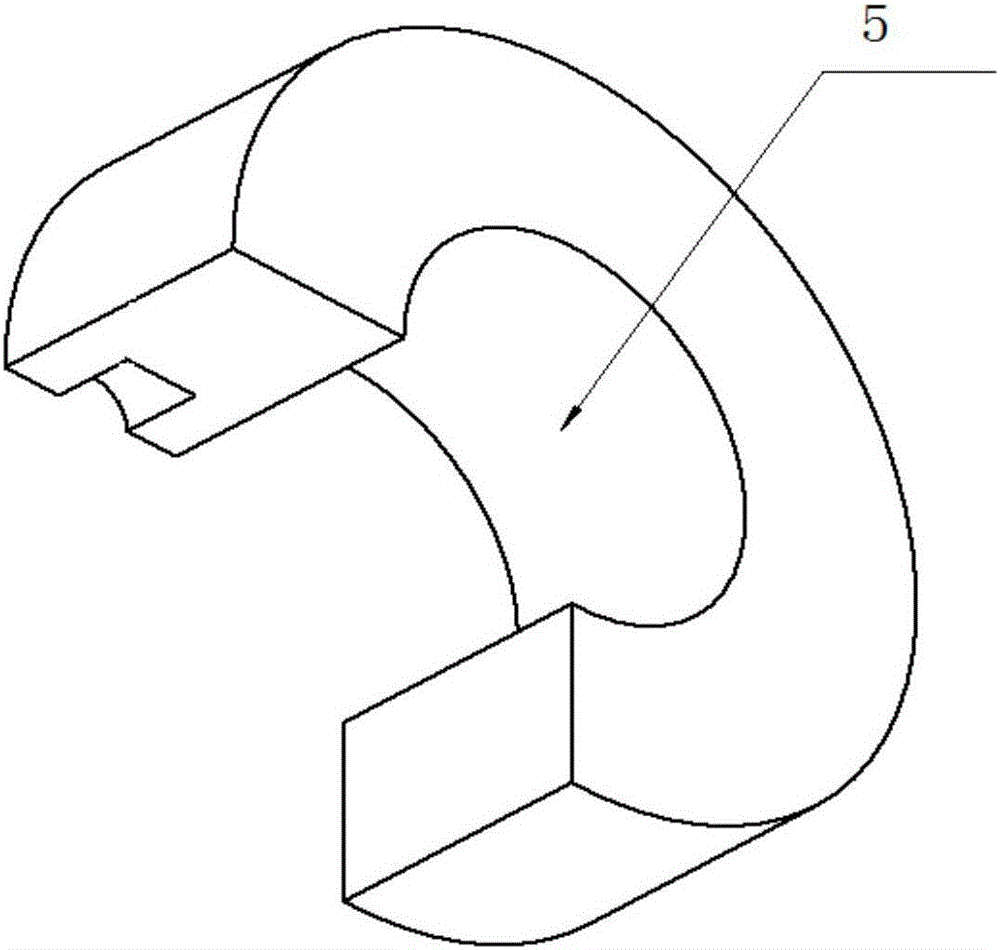

[0020] The inlet of the oil return hole of the valve seat is set correspondingly to the jet area of the nozzle baffle, and the throttling device includes a cone valve core 4 which is threadedly connected with the inner wall of the oil return hole of the valve seat and is threadedly connected with the oil return hole of the valve seat. The cone valve seat 3; the center of the cone valve seat 3 is provided with a first flow hole 5, and the cone valve core 4 is fixedly connected with a cone 7 on the opposite end surface of the cone valve seat 3, and the cone 7 The diameter of the bottom surface of the cone valve core 4 is smaller than the diameter of the cone valve core 4...

Embodiment 2

[0024] Based on the above embodiment, the cone valve core 4 in this embodiment is fixedly connected to the inner wall of the oil return hole of the valve seat, the cone valve core 4 is arranged close to the inlet of the oil return hole of the valve seat, and the cone valve seat 3 is connected to the oil return hole of the valve seat. The opposite end surface of the cone valve core 4 is provided with a screw hole; or,

[0025] The cone valve seat 3 is fixedly connected with the oil return hole of the valve seat, the cone valve seat 3 is set close to the oil return hole of the valve seat, and the cone valve core 4 is set on the opposite end surface of the cone valve seat 3 With screw holes.

[0026] In this embodiment, the distance between the cone valve core 4 and the adjustable cone valve can be changed by screwing the screw hole, and then the flow area of the orifice can be adjusted to achieve a balance between stability and other flow characteristics, and suppress the self...

Embodiment 3

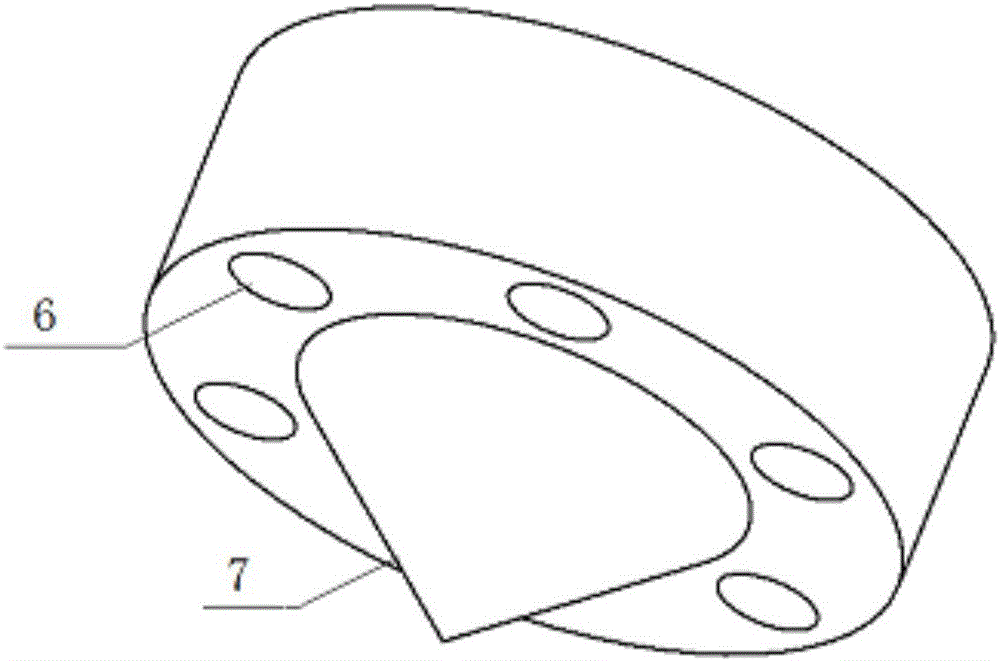

[0028] Based on the above embodiment, the diameter of the bottom surface of the cone 7 at the bottom end of the cone valve core 4 in this embodiment is larger than the diameter of the first flow hole 5;

[0029] The center of the poppet valve core 4 is provided with a third flow hole, and the diameter of the third flow hole is smaller than that of the first flow hole 5;

[0030] The inlet end of the first flow hole 5 on the end surface corresponding to the cone valve seat 3 and the cone valve core 4 is a slope, and the inclination angle is compatible with the cone of the cone valve core 4;

[0031] When the cone of the cone spool 4 enters the first through hole 5 and the cone of the cone spool 4 cooperates with the port on which the first flow hole 5 is inclined, the cone valve The flow between the core 4 and the cone valve seat 3 only passes through the third flow hole and the flow area is the smallest;

[0032] The third flow hole in this embodiment is used to prevent the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com