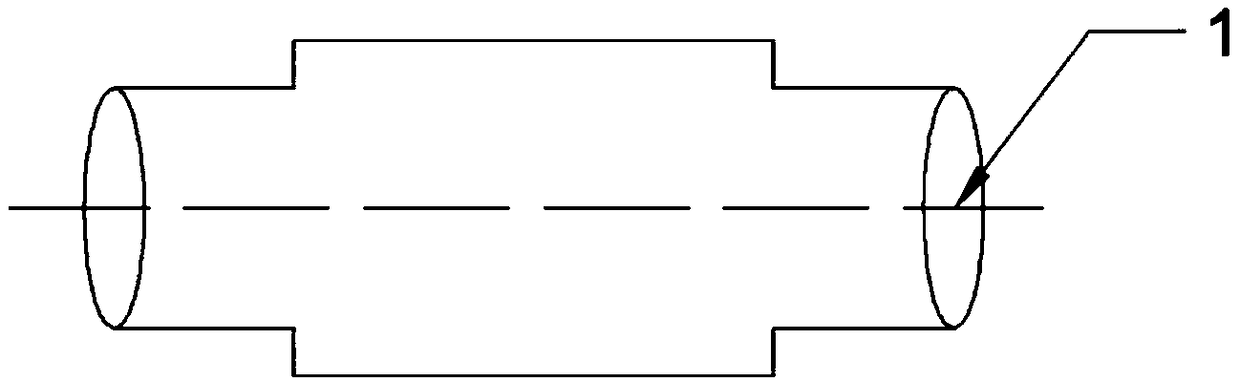

Application of a Titanium-Based Shape Memory Alloy as a Room-Temperature Reaming and Preservation Pipe Joint

A memory alloy, pipe joint technology, applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, mechanical equipment, etc., can solve the problems of increasing cost, restricting the scope of use, etc., to improve the convenience of use and good memory effect. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of high phase transition point Ti-19.5Zr-10Nb-0.5Fe shape memory alloy pipe joints

[0031] (1) Take by weighing the sponge titanium (Ti) that purity is 99.9%, the sponge zirconium (Zr) of 99.7%, the metal niobium (Nb) of 99.9% and a small amount of metal iron (Fe) by weighing;

[0032] (2) Melting the above-mentioned alloy elements in a consumable vacuum electric arc furnace to obtain Ti-19.5Zr-10Nb-0.5Fe shape memory alloy ingot;

[0033] (3) The ingot obtained above is forged and hot-rolled into a plate with a 150 kg forging hammer of a model C41-150.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com