A kind of electrode wire and preparation method thereof

A technology of electrode wire and sheet body, which is applied in the field of electrode wire, can solve problems such as the straightness of the coated electrode wire to be improved, the error of the shape and size of the workpiece, and the backward cutting track of the electrode wire, so as to reduce the contact between electrode wire products, The effect of improving machining accuracy and reducing the probability of wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

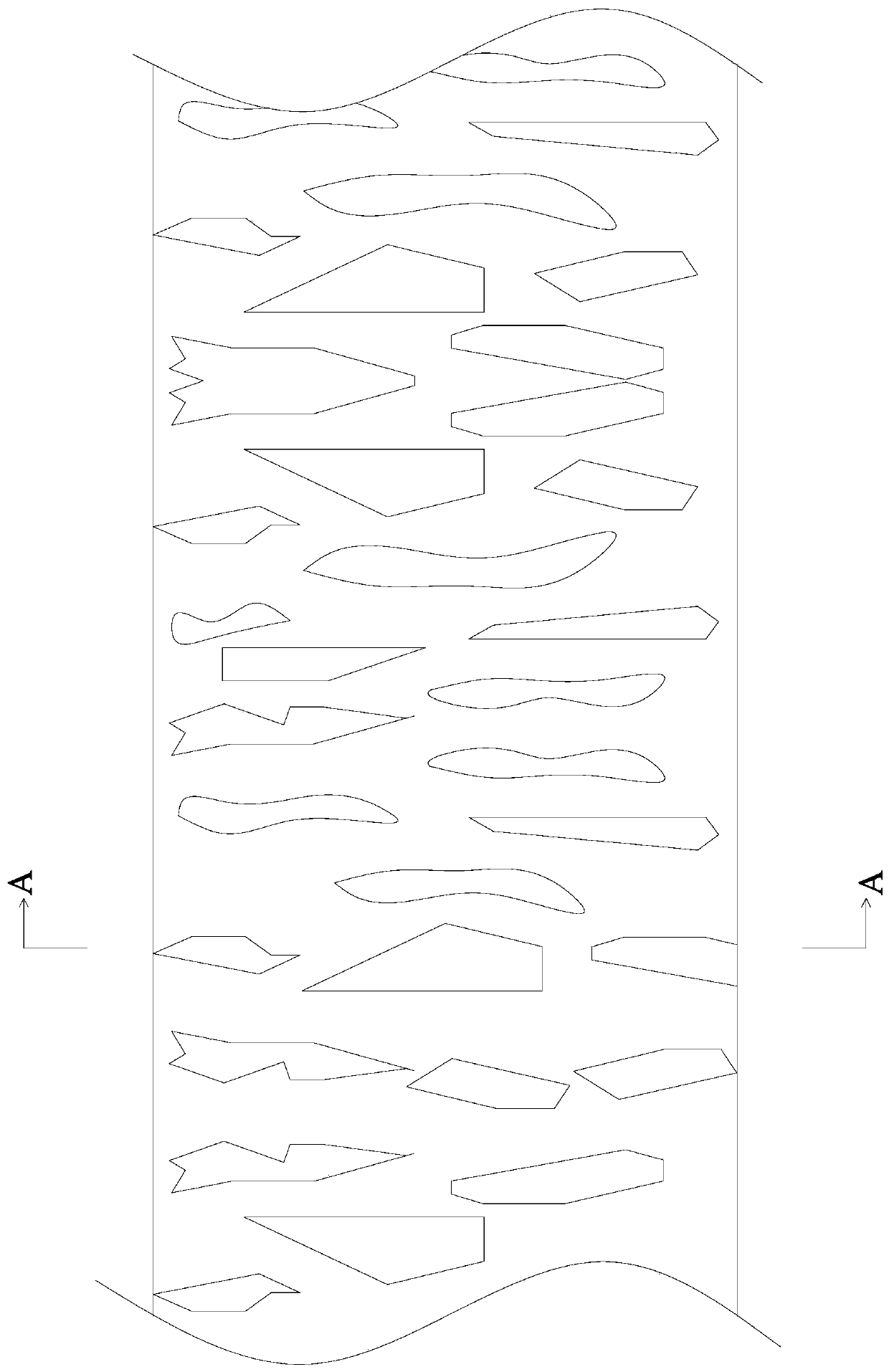

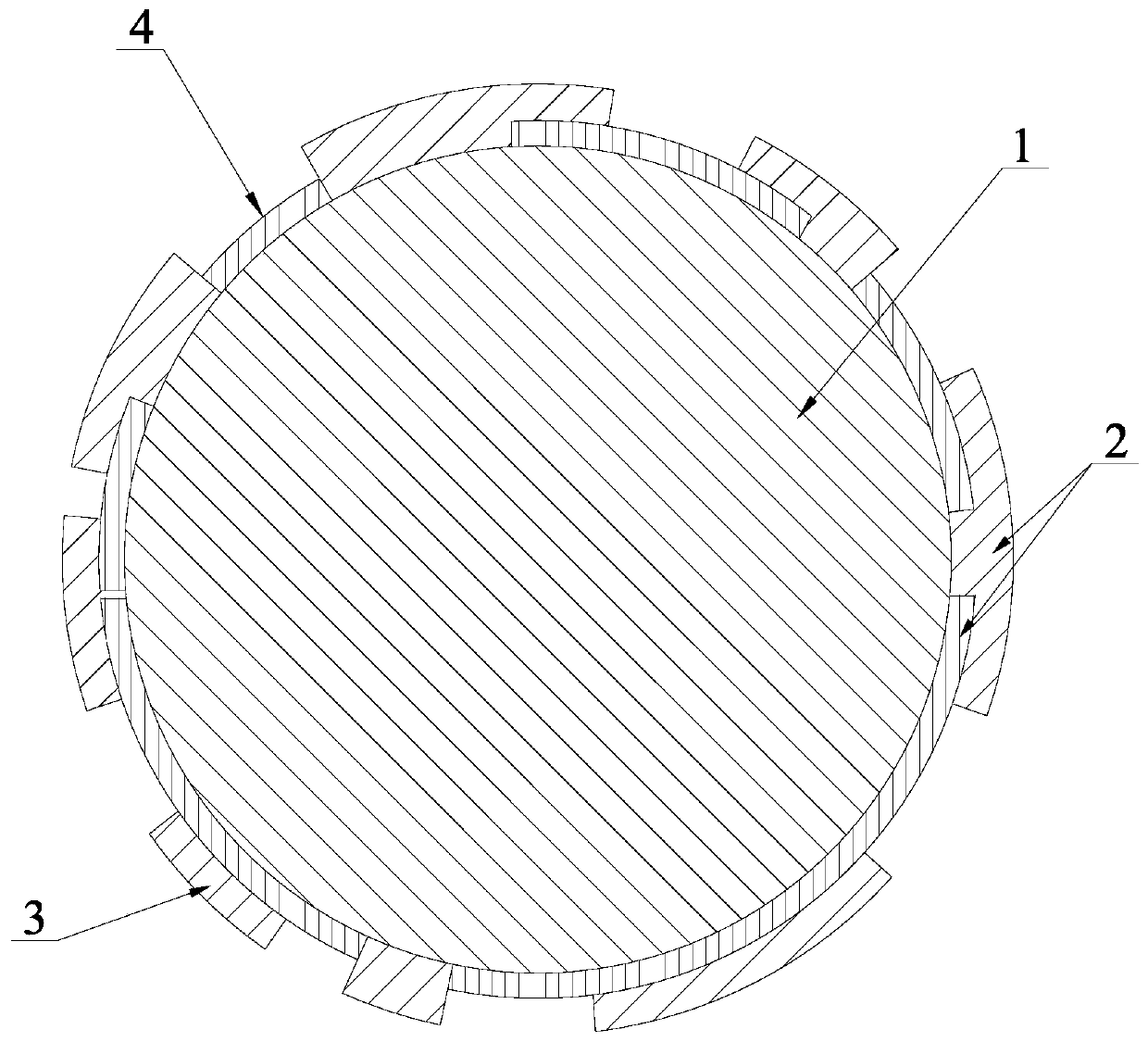

[0063] A method for preparing an electrode wire, comprising the following steps:

[0064] 1) Prepare the busbar with the required diameter of the core material;

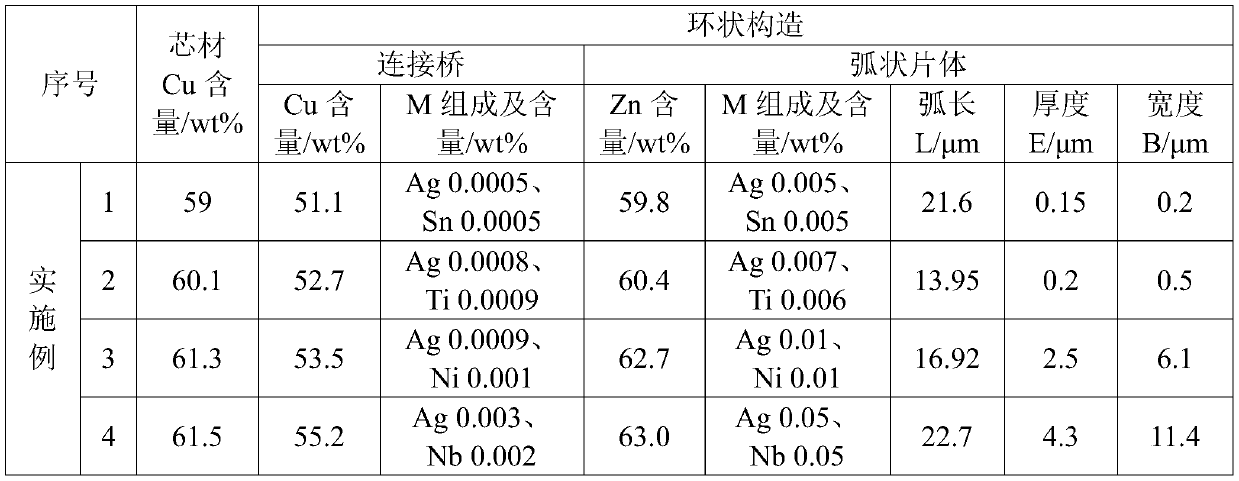

[0065] 2) Degreasing, pickling, water washing and electroplating are performed on the bus bar in sequence to form a zinc coating on the surface of the bus bar; wherein the main salt composition of the electroplating solution used in electroplating is Zn 80-90wt%, M 0.02-6.0wt%, and the rest is Cu and unavoidable impurity elements, and the sum of unavoidable impurity elements content ≤ 0.3wt%; wherein, M is any two elements in Ag, Sn, Ti, Ni, Nb, Mo, Sb, and each element The content range of the electroplating solution is 0.01 to 3wt%. The main salt of the electroplating solution is the metal salt of the coating to be electroplated. The composition of the main salt is represented by the mass ratio of the elements, and the anion of the electroplating solution is SO 4 2- ;

[0066] 3) Stretching the wire blank obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com