Titanium zirconium tantalum shape memory alloy material and preparation method thereof

A memory alloy and alloy material technology, applied in the field of preparation of functional materials, can solve problems such as poor biocompatibility, poor corrosion resistance, and limited application fields, and achieve high corrosion resistance, excellent corrosion resistance, and good biophase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

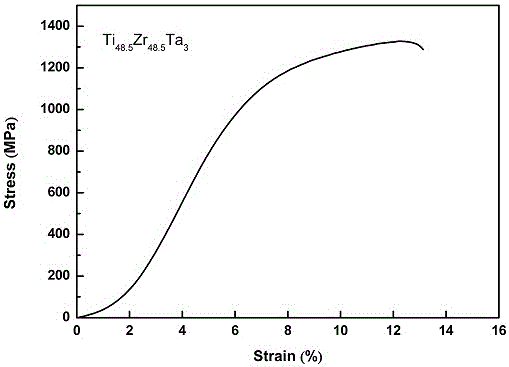

[0034] In this embodiment, a titanium zirconium tantalum shape memory alloy material (Ti 50 Zr 50 ) 97 Ta 3 , calculated according to the percentage of the amount of each component of the alloy material, consists of 48.5 at.% titanium, 48.5 at.% zirconium and 3 at.% tantalum.

[0035] The present embodiment titanium zirconium tantalum shape memory alloy material (Ti 50 Zr 50 ) 97 Ta 3 A preparation method comprising the steps of:

[0036] a. Weigh 48.5 at% purity of 99.99% Ti, 48.5 at.% purity of 99.9% Zr and 3 at.% purity of 99.99% Ta;

[0037] b. Put the Ti, Zr, and Ta weighed in step a into the cold crucible induction suspension melting equipment, and vacuumize to 1×10 -3 Torr, filled with high-purity argon gas with a purity of 5 N, adjusted the power to 40 kW for preheating, and then adjusted the power to 100 kW for melting, then solidified the titanium-zirconium-tantalum alloy melt, and finally obtained the titanium-zirconium-tantalum alloy casting. ingot.

[0...

Embodiment 2

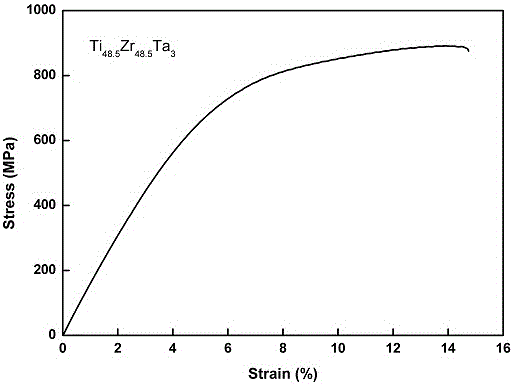

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

[0041] In this embodiment, a titanium zirconium tantalum shape memory alloy material (Ti 50 Zr 50 ) 95 Ta 5 , calculated according to the percentage of the amount of each component of the alloy material, consists of 47.5 at.% titanium, 47.5 at.% zirconium and 5 at.% tantalum.

[0042] The present embodiment titanium zirconium tantalum shape memory alloy material (Ti 50 Zr 50 ) 95 Ta 5 A preparation method comprising the steps of:

[0043] a. Weigh 47.5 at.% of Ti with a purity of 99.99%, 47.5 at.% of Zr with a purity of 99.9% and 5 at.% of Ta with a purity of 99.99%;

[0044] b. This step is the same as the first embodiment.

[0045] In this example, see Figure 4 ~ Figure 6 , using the method of wire cutting, cut a cylinder with a diameter of d = 3 mm and a height of h = 6 mm from the titanium-zirconium-tantalum shape memory alloy obtained in this embodiment as a test sample for c...

Embodiment 3

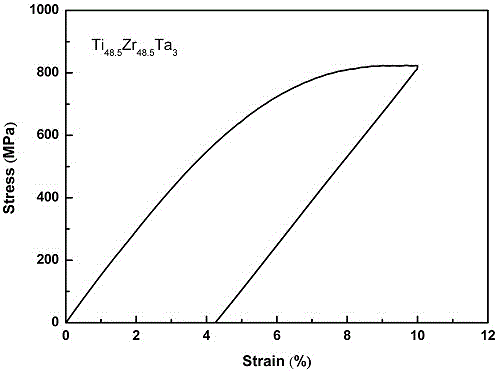

[0047] This embodiment is basically the same as the previous embodiment, and the special features are:

[0048] In this embodiment, a titanium zirconium tantalum shape memory alloy material (Ti 50 Zr 50 ) 93 Ta 7 , calculated according to the percentage of the amount of each component of the alloy material, consists of 46.5 at.% titanium, 46.5 at.% zirconium and 7 at.% tantalum.

[0049] The present embodiment titanium zirconium tantalum shape memory alloy material (Ti 50 Zr 50 ) 93 Ta 7 A preparation method comprising the steps of:

[0050] a. Weigh 46.5 at.% of Ti with a purity of 99.99%, 46.5 at.% of Zr with a purity of 99.9% and 7 at.% of Ta with a purity of 99.99%;

[0051] b. This step is the same as the first embodiment.

[0052] In this example, see Figure 7 ~ Figure 9 , using the method of wire cutting, cut a cylinder with a diameter of d = 3 mm and a height of h = 6 mm from the titanium-zirconium-tantalum shape memory alloy obtained in this embodiment a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com