Spliced lamp bar and lamp bar splicing device

A light strip and magnetic device technology, which is applied in the direction of lighting devices, lighting device components, circuit layout, etc., can solve the problems of unsightly appearance, difficulty in adapting to the predetermined installation position, limited application range, etc., and achieve the effect of reducing dark areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

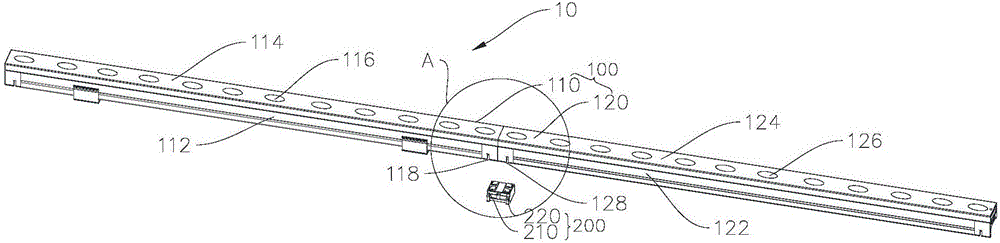

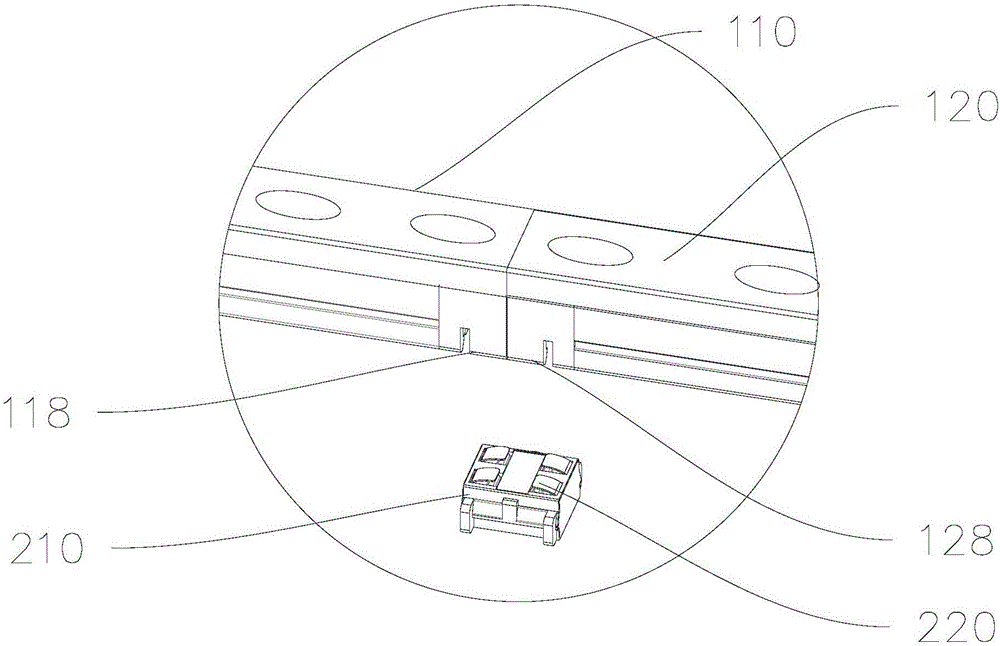

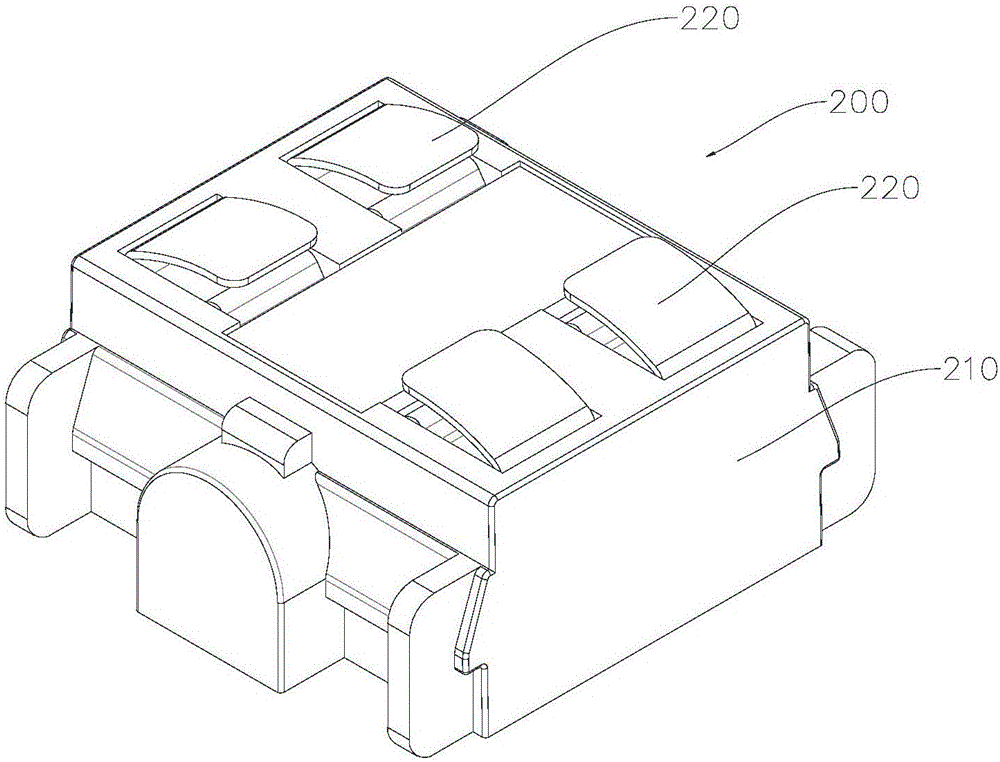

[0034]Please refer to figure 1 and figure 2 , this embodiment provides a splicing light bar 10, which includes a light bar 100 and a splicing component 200, wherein the light bar 100 includes a first light bar 110 and a second light bar 120, and the first light bar 110 and The second light bar 120 is physically connected and electrically connected through the splicing component 200 .

[0035] In this embodiment, the first light bar 110 includes a first housing 112, a first light source board 114, and a plurality of first lamp beads 116. As a method, the first housing 112 is provided with a strip-shaped groove , the groove matches the first light source board 114, and the first light source board 114 is disposed in the groove of the first housing 112, wherein the first light source board 114 is a PCB board. The plurality of first lamp beads 116 are arranged on the first light source board 114. It can be understood that the plurality of first lamp beads 116 are arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com