A high-precision four-channel gas ultrasonic flow transmitter

A four-channel, ultrasonic technology, used in liquid/fluid solid measurement, flow/mass flow measurement, instruments, etc., can solve problems such as long time-consuming digital signal processing, long time interval between excitation moments, and linear velocity deviation of gas flow , to achieve the effect of improving real-time performance and measurement accuracy, and shortening the excitation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

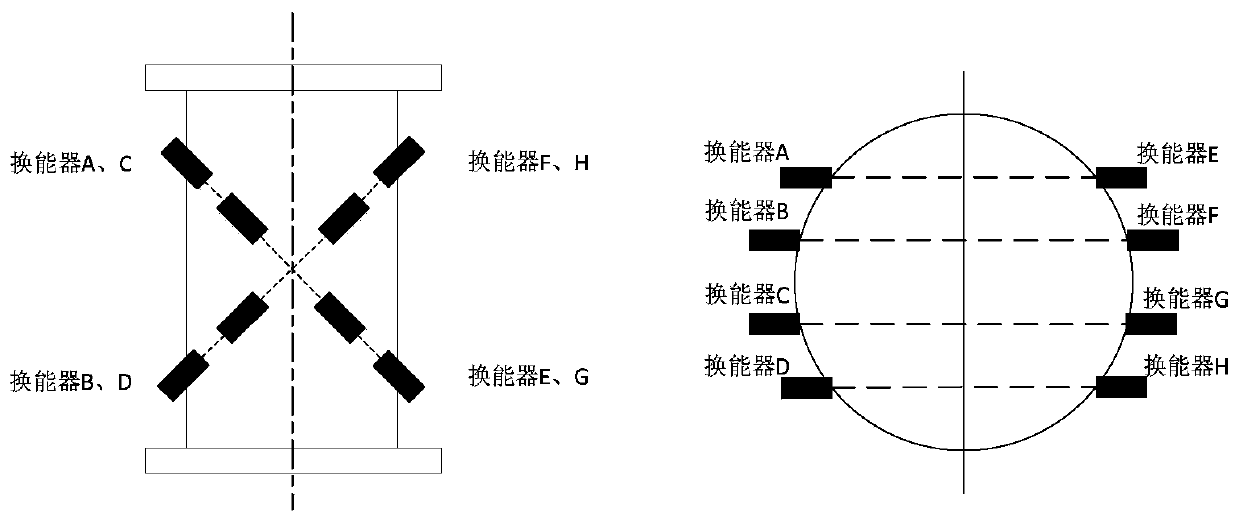

[0067] see figure 1 , The primary instrument of the present invention is composed of eight gas ultrasonic transducers, flow tubes and installation components. The eight gas ultrasonic transducers are respectively transducer A, transducer B, transducer C, transducer D, transducer E, transducer F, transducer G and transducer H , each transducer acts as both a transmitting transducer and a receiving transducer. The eight ultrasonic transducers form four sound channels, which are respectively transducer A and transducer E (marked as sound channel 1), transducer B and transducer F (marked as sound track 2), Transducer C and transducer G (recorded as channel 3), transducer D and transducer H (represented as channel 4), the channel lengths of said channel 1 and channel 4 are relatively short, The channel lengths of the channels 2 and 3 are relatively long.

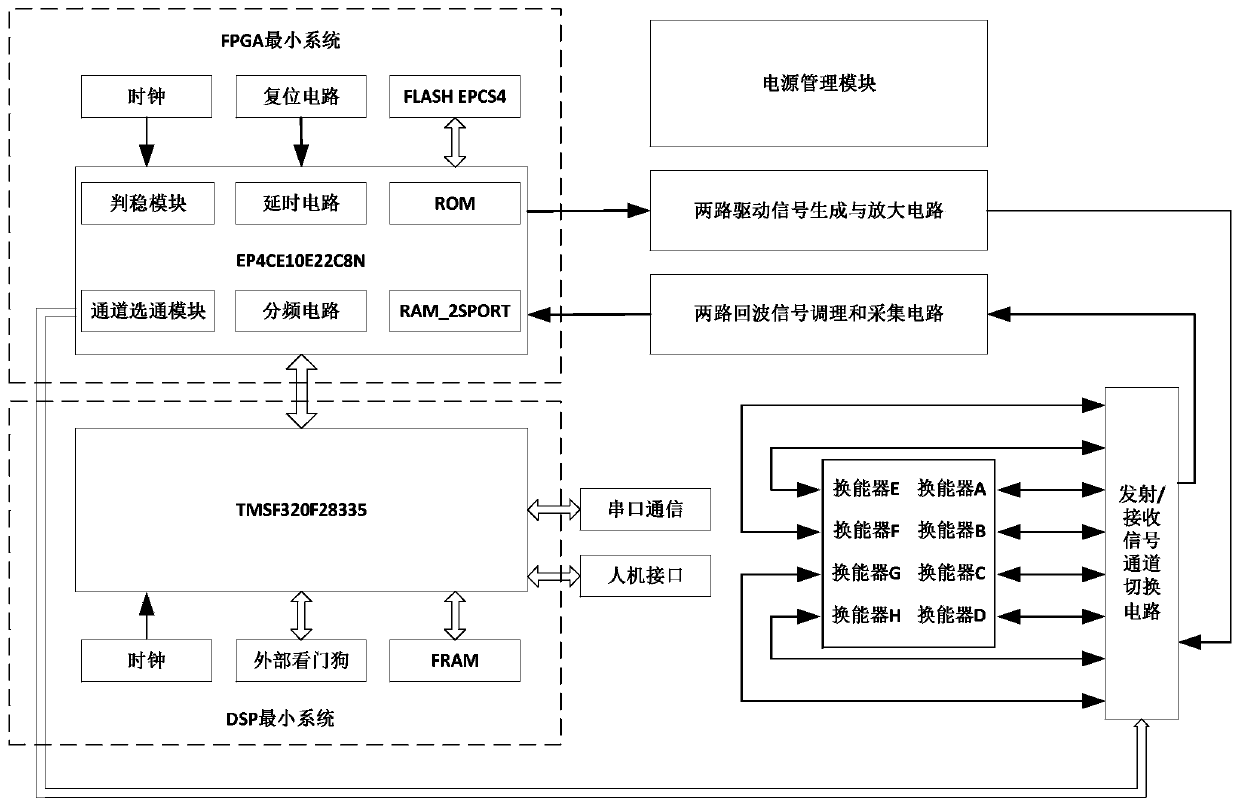

[0068] see figure 2 , the secondary instrument hardware system of the present invention consists of a transmission / recepti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com