Electronic display glass cover plate surface defect detection system and method

A technology of glass cover and detection system, which is applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problem of misjudgment or missed detection by inspectors, differences in detection results of people with different vision, and constraints on enterprise development and Improve enterprise efficiency and other issues, to achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

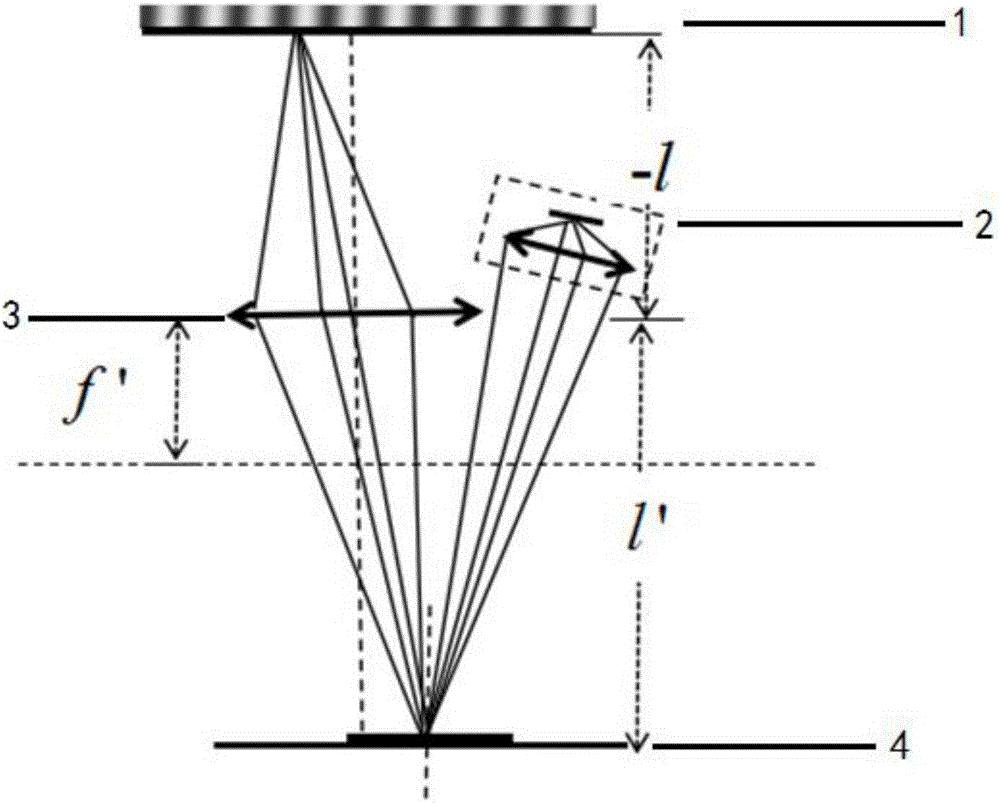

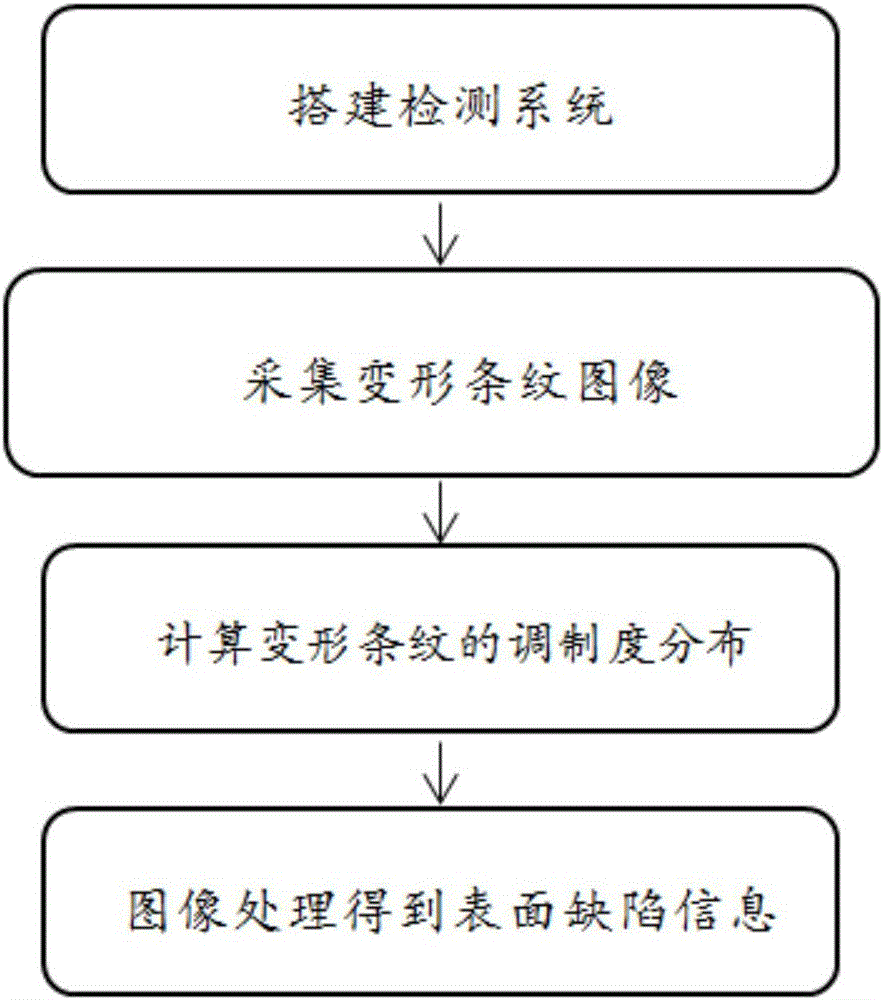

[0051] Such as figure 2 Shown, a kind of detection method of the glass cover plate surface defect of electronic display screen comprises the following steps:

[0052] Step A: Build a detection system for the oblique structure of the front projection:

[0053] Place the structured light illuminating device 1 in parallel directly above the surface 4 to be tested of the electronic display glass cover of the object to be measured, and place the lens 3 between the structured light illuminating device 1 and the electronic display glass cover, and the structured light illuminating device 1 is imaged on the surface 4 of the electronic display glass cover plate to be tested by the lens 3, and the structured light lighting device 1, lens 3, and the test surface 4 of the electronic display glass cover plate satisfy the Gaussian formula: Among them: l is the object distance, that is, the distance between the structured light lighting device and the main surface of the lens, l' is the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com