A VPCE static performance testing method

A test method and technology for static performance, applied in the field of thermonuclear fusion reaction research, can solve the problems of lack of targeted research methods, poor comprehensive performance evaluation of catalyst components, and unfavorable selection of catalyst components, achieving low hybrid interference and improved performance. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

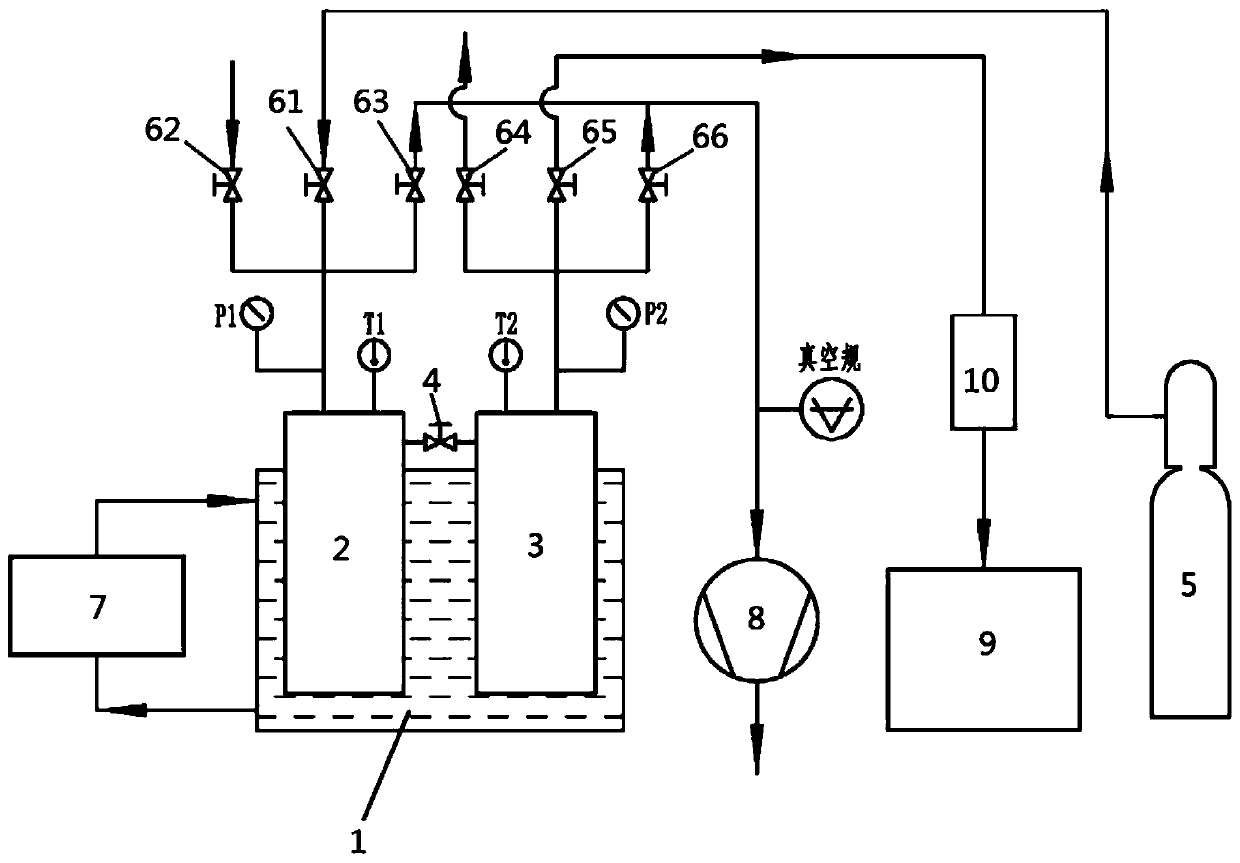

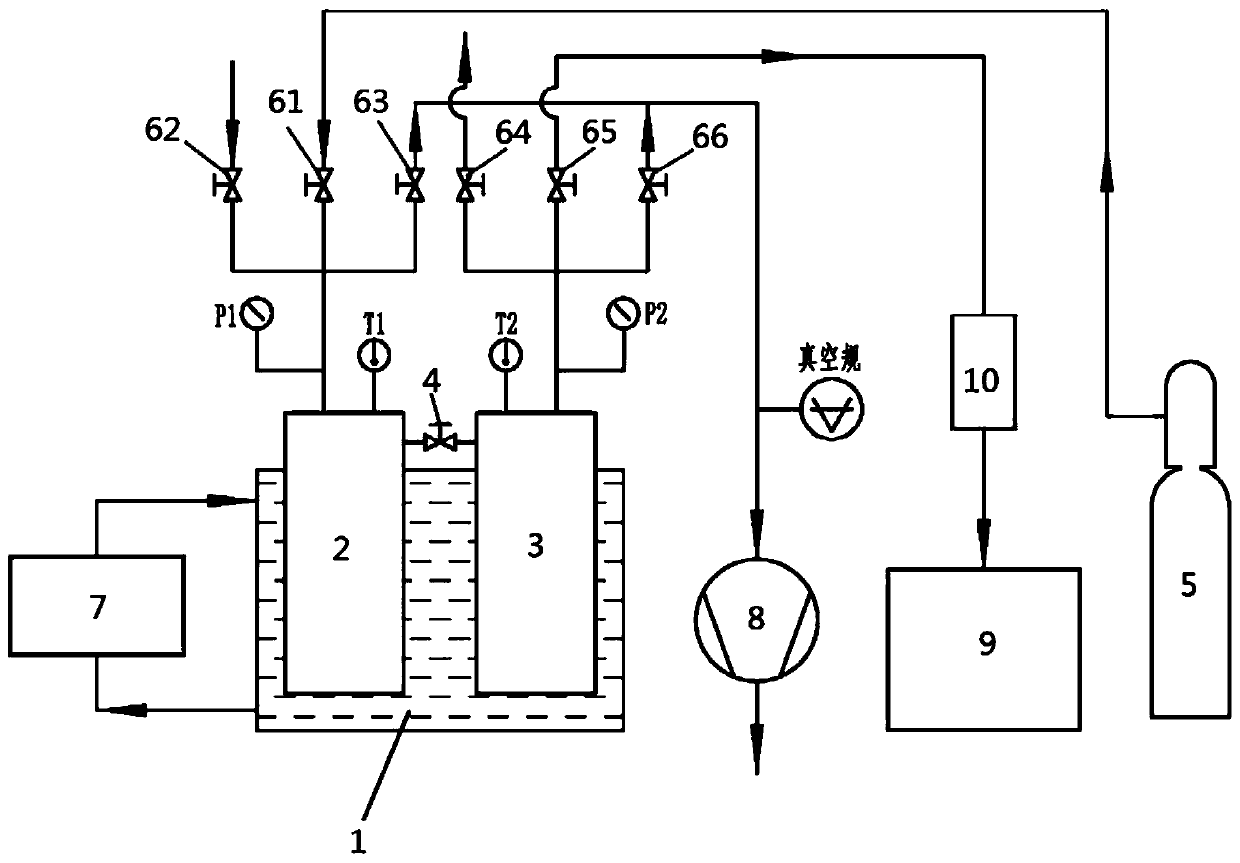

[0039] Such as figure 1 The shown VPCE static performance testing device system includes a constant temperature tank 1 and a mixing tank 2 and a reaction tank 3 arranged in the constant temperature tank 1. A communication valve 4 is arranged between the mixing tank 2 and the reaction tank 3, so that the mixing tank 2 can be realized. It is isolated from the connection and closure of the reaction tank 4. The hydrophilic catalyst to be detected and analyzed is placed in the reaction tank and sealed. Open the first evacuation valve 63, the second evacuation valve 66 and the communication valve 4 to vacuumize the whole system. Then vacuum flushing: pass 99.9% pure hydrogen from the hydrogen tank 5 into the mixing tank 2, then vacuum again, and then pass hydrogen, repeat 3 times to complete the flushing. Finally, the whole system is evacuated to below 50 Pa (absolute atmospheric pressure), and the first evacuation valve 63 , the second evacuation valve 66 and the communication va...

Embodiment 2

[0043] same use figure 1 The device system shown, and the method similar to that of Example 1 was used for online sample testing and analysis: the prepared hydrophilic catalyst was placed in a reaction tank and sealed. Open the evacuation valve 1, the evacuation valve 2 and the connection valve, and perform evacuation and flushing of the entire system. Generally, the evacuation and flow flushing is performed 3 times, and each time the system is filled with pure hydrogen with a purity of more than 99.9%, and finally the entire system is evacuated to Below 50Pa. Close evacuation valve 1, evacuation valve 2 and connecting valve. Open the hydrogen injection valve, inject a quantitative amount of more than 99.99% pure hydrogen into the mixing tank, and then close the hydrogen injection valve. Open the injection valve, inject a certain amount of deuterium-containing water (HDO) into the mixing tank, and close the hydrogen injection valve. Turn on the oil bath device to keep the t...

Embodiment 3

[0049] The same VPCE static performance test method as in Example 1 was used to study and analyze the reaction of the heavy aqueous solution in the device system.

[0050] First, test the static balance of the system

[0051] The static equilibrium test is to measure the deuterium content in hydrogen after the deuterium-containing water and hydrogen fully react to reach equilibrium under the action of a catalyst and at a certain temperature and pressure, and record the parameter results of the specific test. The specific test and analysis process includes the following process: 1) The temperature, pressure, and feed ratio (the ratio of deuterium-containing water to hydrogen substance mass) are constant, and the deuterium content in hydrogen is determined when different catalysts are used; 2) Catalyst, temperature, and feed ratio Certain, when adopting different reaction pressures, deuterium content in hydrogen. 3) The catalyst, pressure, and feed ratio are constant, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com