Welding device

A welding device and connecting technology, which is applied to the parts of the connecting device, the coupling device, the device for connecting/disconnecting the connecting parts, etc. Disengagement or looseness, preventing plugging looseness, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

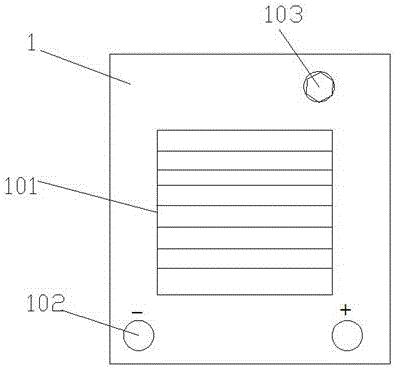

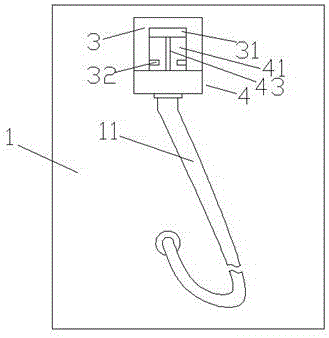

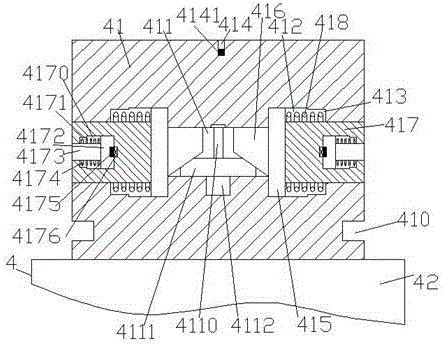

[0023] Such as Figure 1-Figure 7 As shown, a welding device of the present invention includes a connecting piece 51 installed in the socket 5, an electric welding machine 1, an adapter 3 fixed on the rear side of the electric welding machine 1, and an In the connecting part 4 inside, a heat exhaust window 101 is provided in the middle of the front end of the electric welding machine 1, and a positive and negative output port 102 is provided on the front end of the electric welding machine 1 below the heat exhaust window 101. The front end of the electric welding machine 1 on the upper right of the heat window 101 is provided with an adjustment hinge 103, and the connecting part 4 includes a connecting head 41 and a pinching member 42 fixed on the bottom of the connecting head 41. A groove 414 is arranged in the top end surface of the head 41, and a trigger 4141 is arranged in the groove 414. A first sliding cavity 411 is arranged in the coupling head 41 below the groove 414. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com