Automatic temperature-control electric tracing band

An electric heating cable and self-controlling temperature technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of poor stability, high cost, complex structure of parallel electric heating cables, etc., and achieve the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

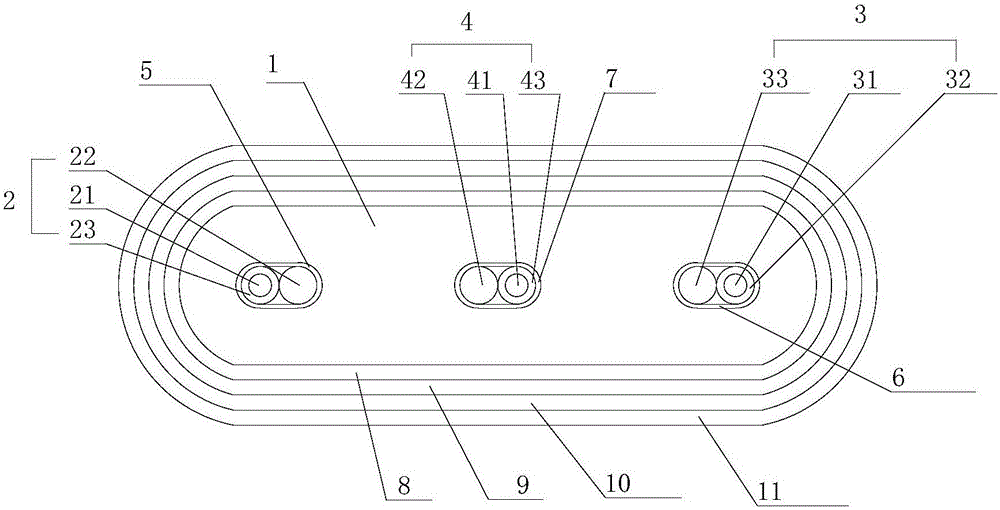

[0013] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a self-controlling electric heating cable proposed by the present invention.

[0014] refer to figure 1 , the present invention proposes a self-controlling electric heating cable, including a PTC material core 1 .

[0015] The PTC material core 1 is made of carbon-added conductive plastic, and the PTC material core 1 is equipped with a first main heating core 2, a second main heating core 3, and a secondary heating core 4 extending along the length of the cable. , the first main heating core 2, the second main heating core 3, and the auxiliary heating core 4 are arranged side by side, and the auxiliary heating core 4 is the midpoint of the connecting line between the first main heating core 2 and the second main heating core 3 Location.

[0016] The first main heating core 2 is twisted by the first conductor 21 and the first carbon fiber bundle 22, the outer circumference of the first conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com