Synthetic resin container lid

A technology for synthetic resin and container caps, which is applied in the direction of synthetic resin layered products, bottles/container caps, and containers tightly closed with caps, which can solve problems such as inability to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

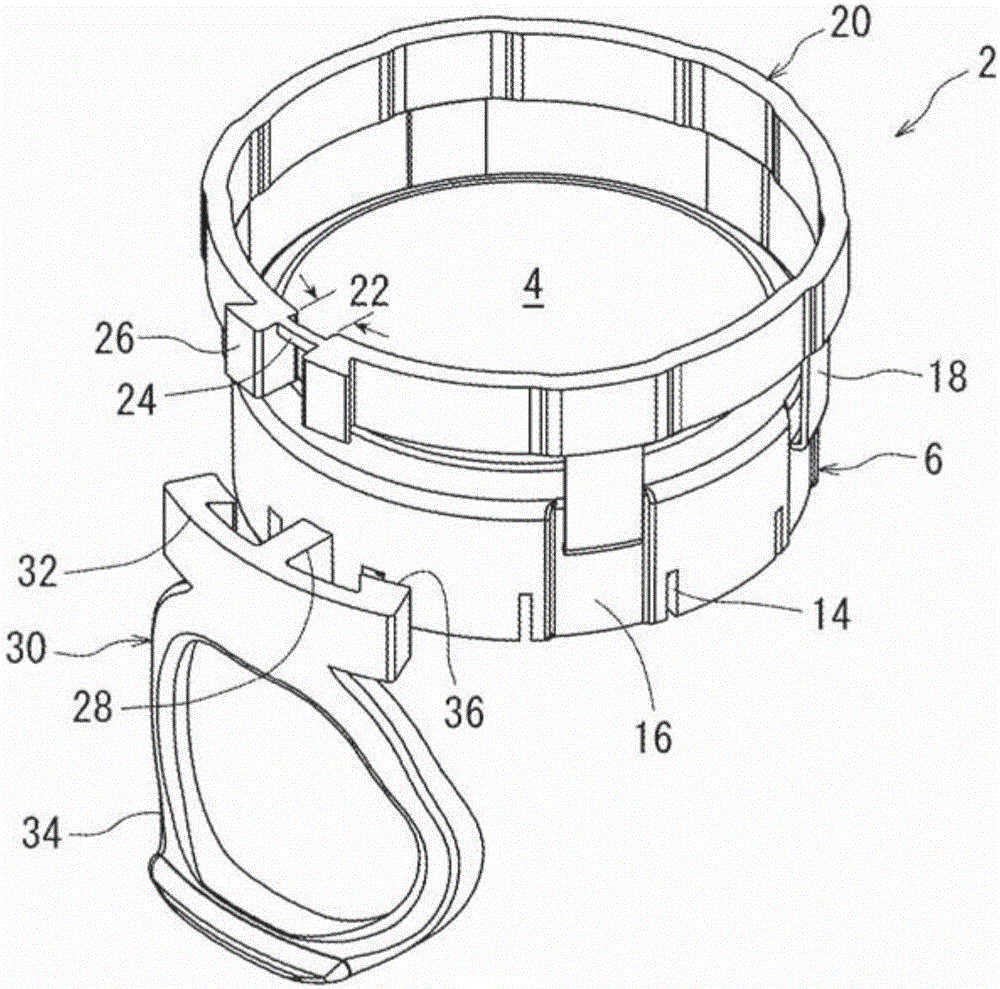

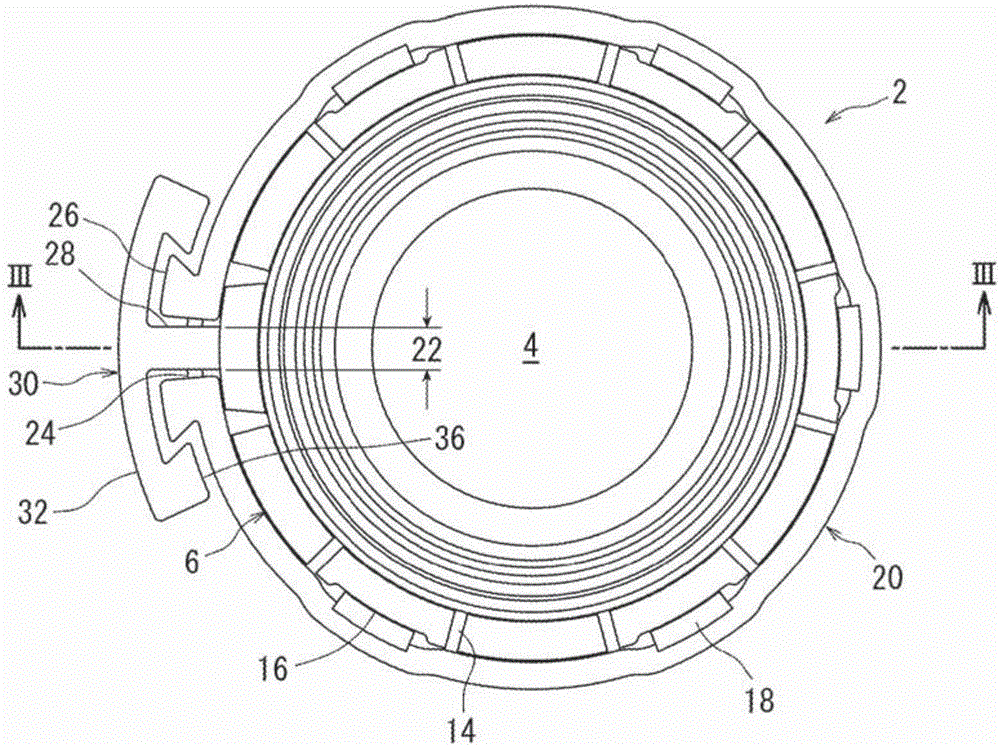

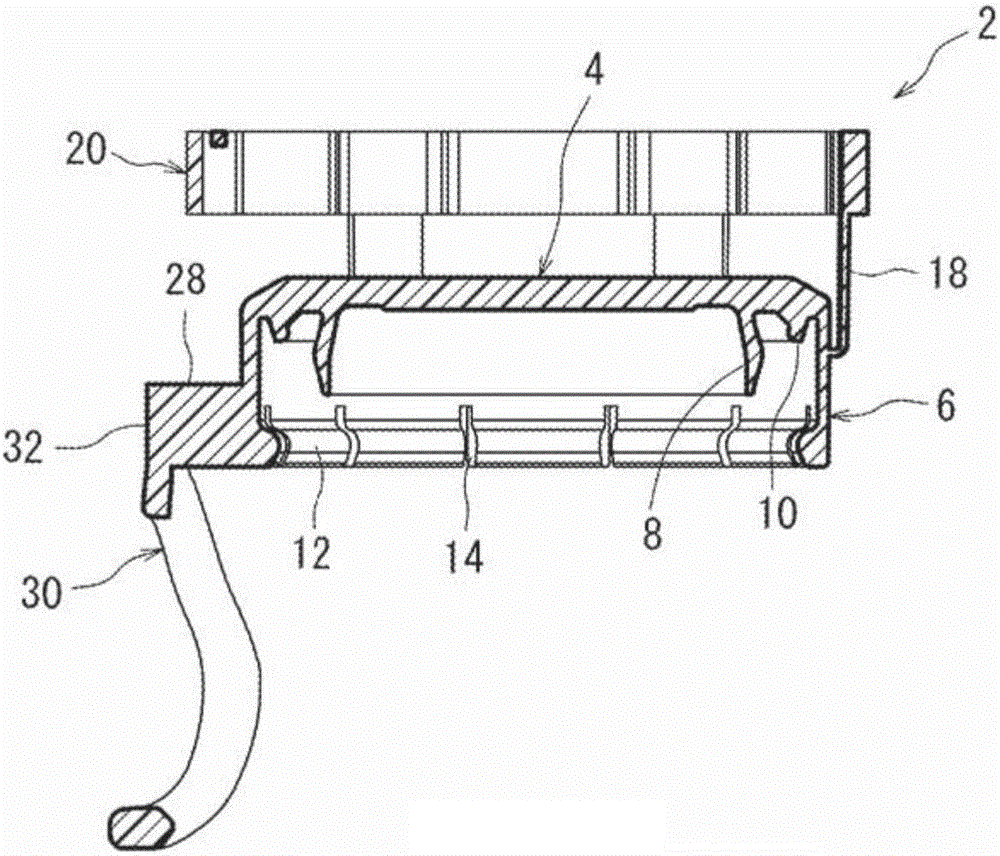

[0026] Now, the present invention will be described in more detail with reference to the accompanying drawings showing a synthetic resin container cap constructed according to the present invention.

[0027] see Figure 1 to Figure 3 , the container lid shown here and marked with 2 as a whole may be integrally injection molded or compression molded from a suitable synthetic resin such as polyethylene or polypropylene, the container lid comprising a top wall 4 and a top wall 4 downwardly from the periphery Extended skirt wall 6 . The top wall 4 is circular in plan view and has a flat central portion and a peripheral portion inclined downward in the radially outward direction. Such as image 3 As clearly shown, two annular seals protruding downwards, an inner seal 8 and an outer seal 10 , are provided in the peripheral portion of the inner surface of the top wall 4 .

[0028] The skirt wall 6 is approximately cylindrical as a whole. An annular locking ridge 12 is formed in t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap