Solid fertilizer anti-blocking feeding fertilizer applicator

A fertilizer applicator and anti-blocking technology, which is applied to fertilization devices, fertilizer distributors, applications, etc., can solve the problems of reduced fertilizer application quality, influence of fertilizer discharge, large structural size, etc., and achieves compact structure and reliable operation. , the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

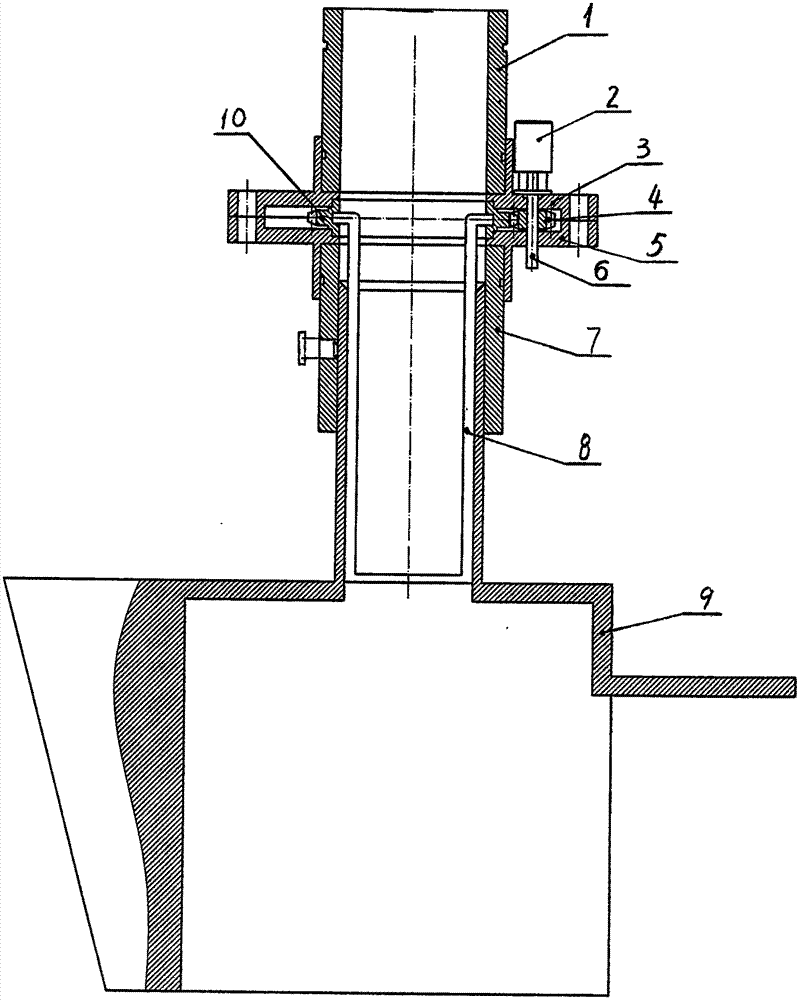

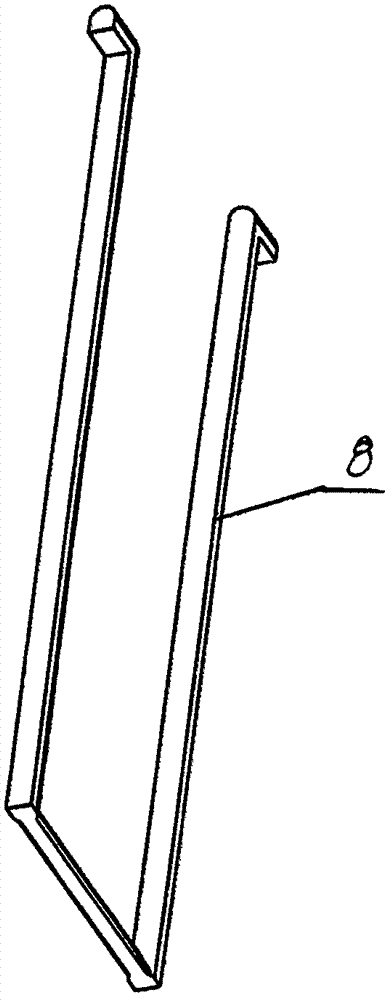

[0010] The following describes the creative implementation of the present invention in detail with reference to the accompanying drawings. A solid chemical fertilizer anti-blocking discharge fertilizer applicator includes a shoe-type ditching fertilizer applicator 9, and an annular outer ring gear 10 and a driving gear are rotatably equipped in a housing cavity assembled by an upper shell 3 and a lower shell 5 4. The annular outer ring gear 10 meshes with the driving gear 4, and the fertilizer pipe 1 and the motor 2 are respectively fixedly mounted on the upper end of the upper housing 3, and the driving gear 4 is fixed to the motor of the motor 2 On the shaft 6, a lower fertilizer pipe 7 is fixedly mounted on the lower end of the lower shell 5. The shoe-type ditch fertilizer applicator 9 is installed on the lower fertilizer pipe 7 so as to be adjustable up and down. An anti-blocking stirring scraper 8 is installed on the side wall of the inner hole and located inside the shoe-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com