Self-circulation soaking treatment device

A processor and self-circulation technology, which is used in packaging objects, packaging, food science and other directions under special gas conditions. The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

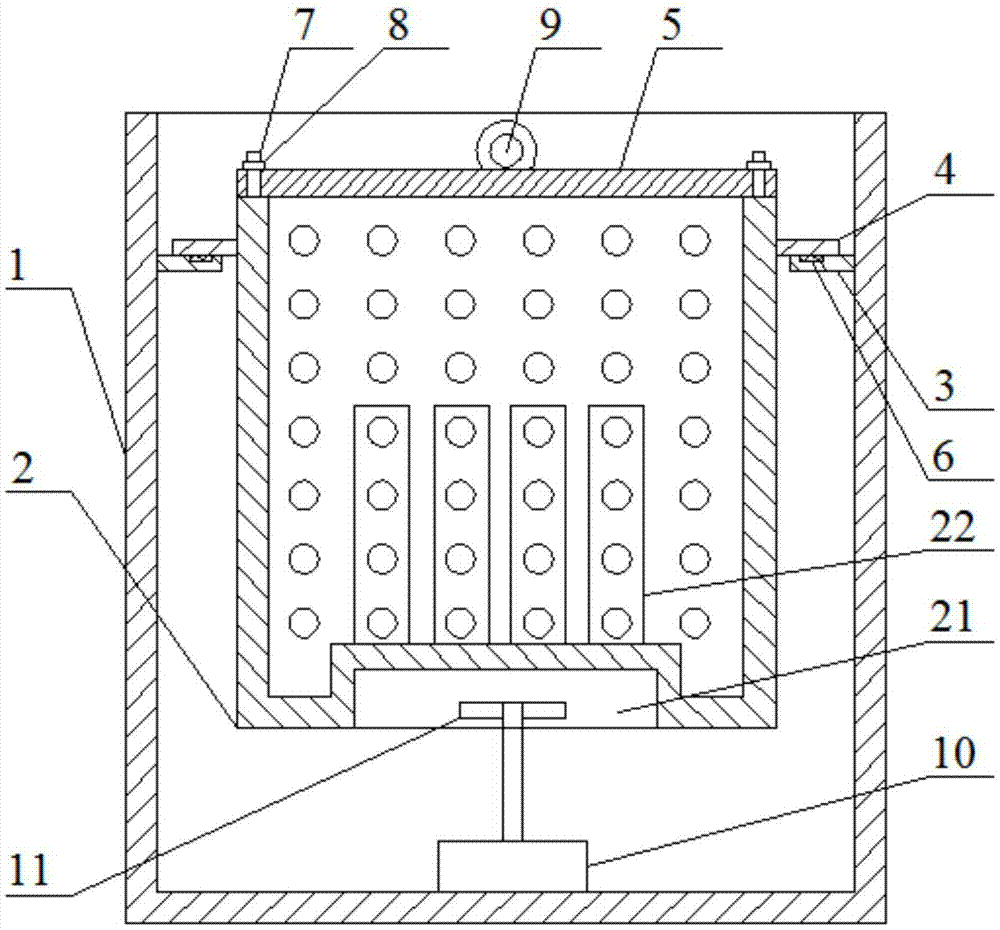

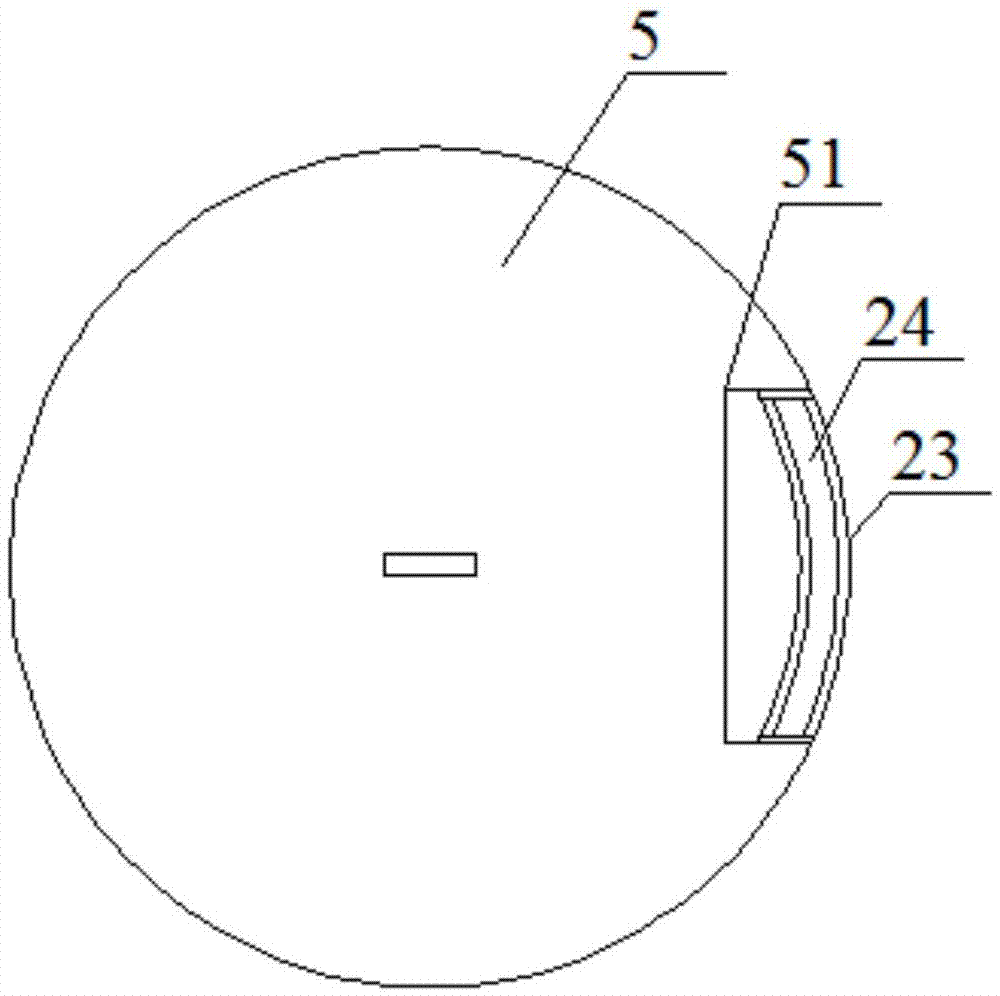

[0030] Such as figure 1 and figure 2 As shown, the self-circulation soaking processor includes an outer barrel 1, an inner barrel 2, an outer fixing ring 3, an inner fixing ring 4, and an inner barrel cover 5; the outer fixing ring 3 is fixed on the inner surface of the outer barrel 1, and the inner fixing ring 4 is fixed on The outer surface of the inner barrel 2, the inner barrel 2 is arranged in the outer barrel 1, and the inner barrel 2 is suspended on the outer fixing ring 3 through the inner fixing ring 4; the inner barrel cover 5 is arranged on the top of the inner barrel 2; the inner barrel 2 is made of a perforated plate; Concave inwardly to form accommodating chamber 21, the top of accommodating chamber 21 is inwardly recessed to form a plurality of upwardly protruding inward concave sections 22; it also includes a motor 10 arranged at the bottom of outer tub 1, and the output end of motor 10 is upward; The output end of the motor 10 is connected to the impeller 11...

Embodiment 2

[0036] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment further includes a sealing ring 6 disposed on the upper surface of the outer fixing ring 3 , and the sealing ring 6 is in contact with the lower surface of the inner fixing ring 4 .

[0037] A sealing ring 6 is provided to prevent soaking liquid from overflowing from between the outer fixing ring 3 and the inner fixing ring 4 .

Embodiment 3

[0039] Such as figure 1 As shown, on the basis of Embodiment 1, the present embodiment also includes a plurality of screw rods 7 arranged vertically on the top of the inner barrel 2, and the screw rods 7 run through the inner barrel cover 5; The inner barrel cover 5 is pressed on the top of the inner barrel 2.

[0040] The inner barrel cover 5 is pressed tightly on the top of the inner barrel 2 to avoid the flow of the soaking liquid and the inner barrel cover 5 is pushed away, thereby improving the working reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com