Puncture needle positioning device

A positioning device and puncture needle technology, applied in the direction of puncture needles, trocars, medical science, etc., can solve the problem of not being able to grasp the angle of the puncture needle, not having the ability to adjust the angle of the puncture needle, and the guiding device cannot assist doctors in judging the needle entry point The exact position and other issues can be avoided to avoid contamination and infection, reduce operation time, and improve efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

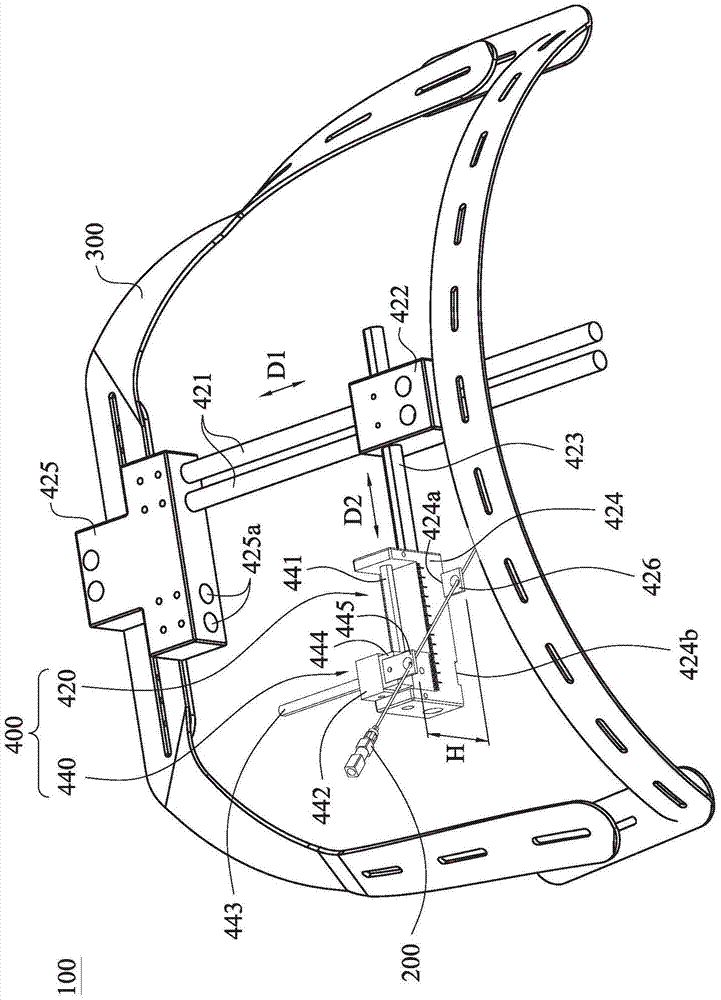

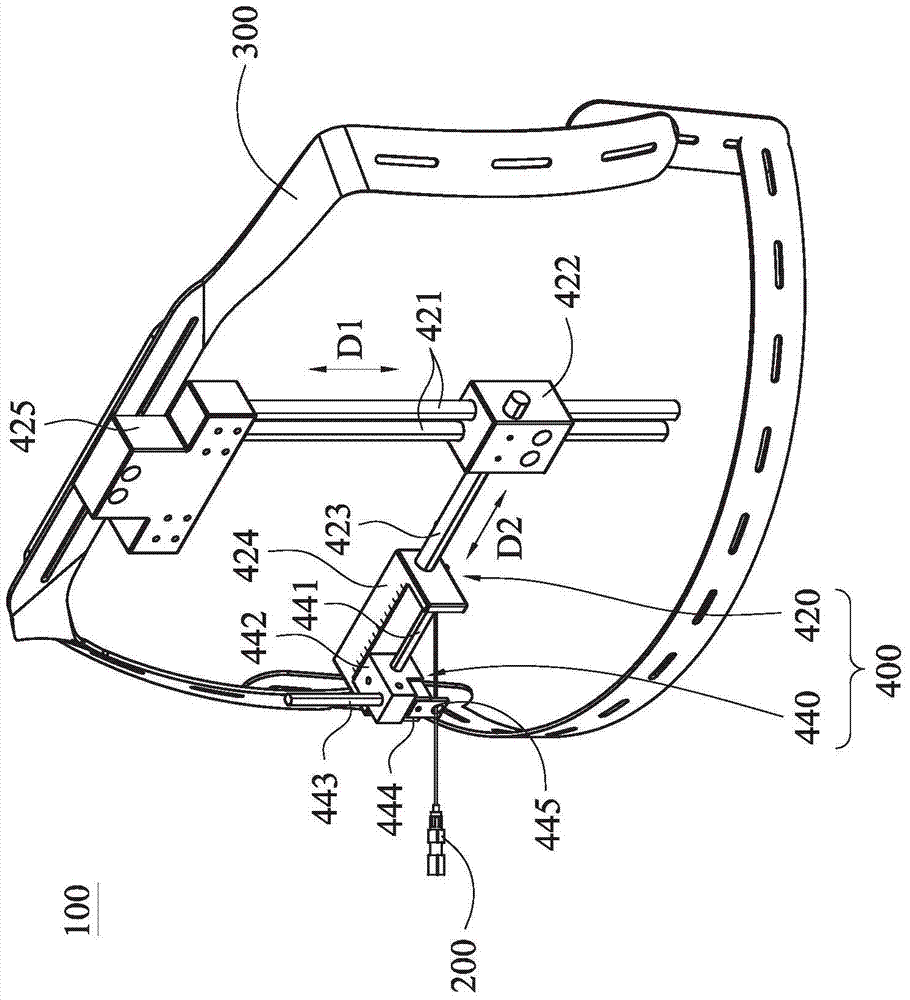

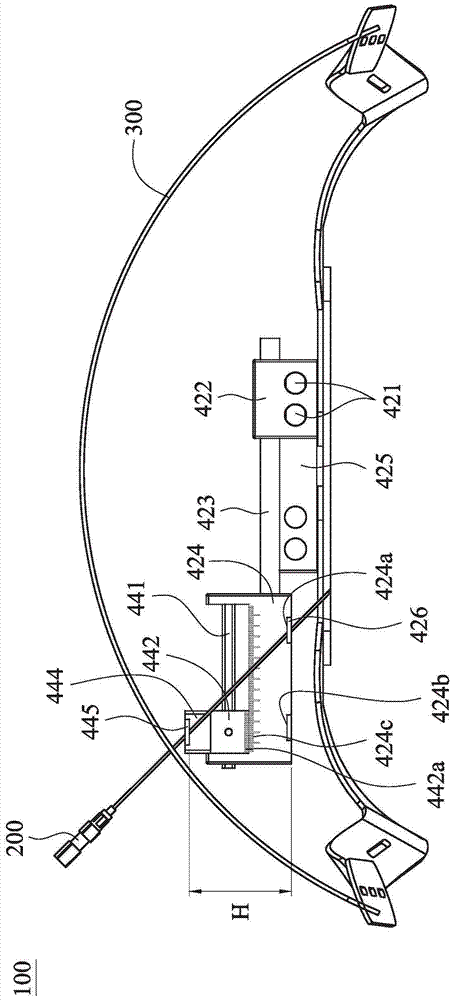

[0022] Please also refer to figure 1 and figure 2 , which are device schematic diagrams respectively showing two different angles of a puncture needle positioning device according to an embodiment of the present invention. The puncture needle positioning device 100 of this embodiment can be directly worn by the patient, and the doctor can operate the puncture needle positioning device 100 to adjust and position the puncture needle 200, thereby preventing the patient from moving relative to the puncture needle positioning device 100, and further The needle insertion position and needle insertion angle of the puncture needle 200 are determined to achieve the purpose of improving the accuracy and success rate of the puncture operation.

[0023] Please continue to refer to figure 1 and figure 2 , the puncture needle positioning device 100 mainly includes a back frame 300 and a positioning mechanism 400 . In this embodiment, the back frame 300 is mainly worn on the human body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com