A two-way locking mechanism

A locking mechanism and locking technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as energy waste and work efficiency cannot be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

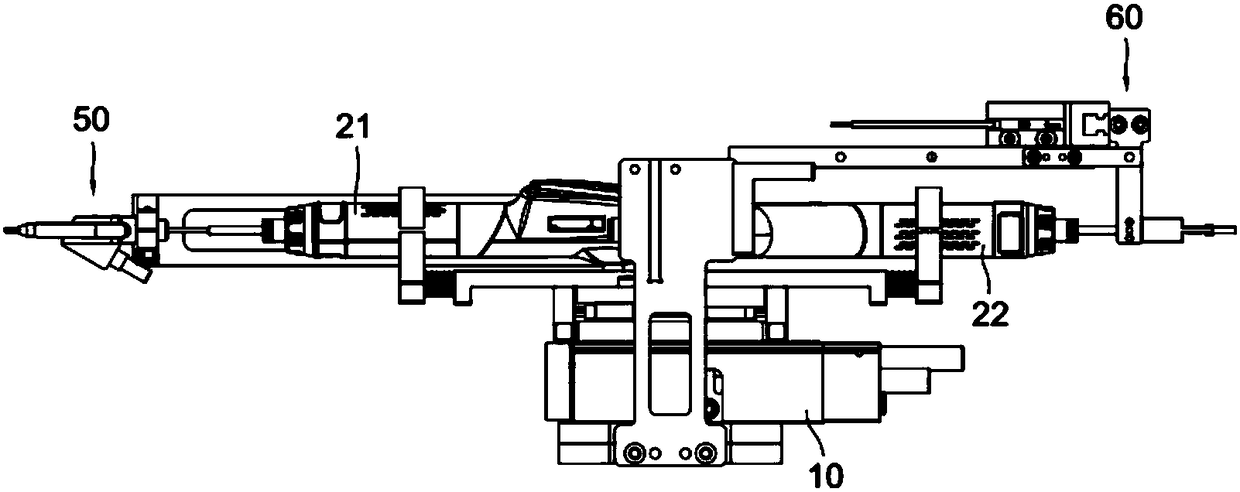

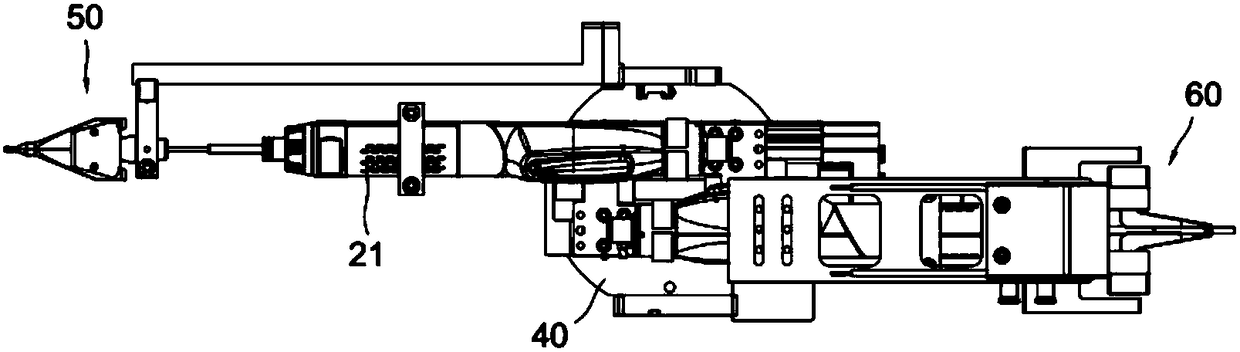

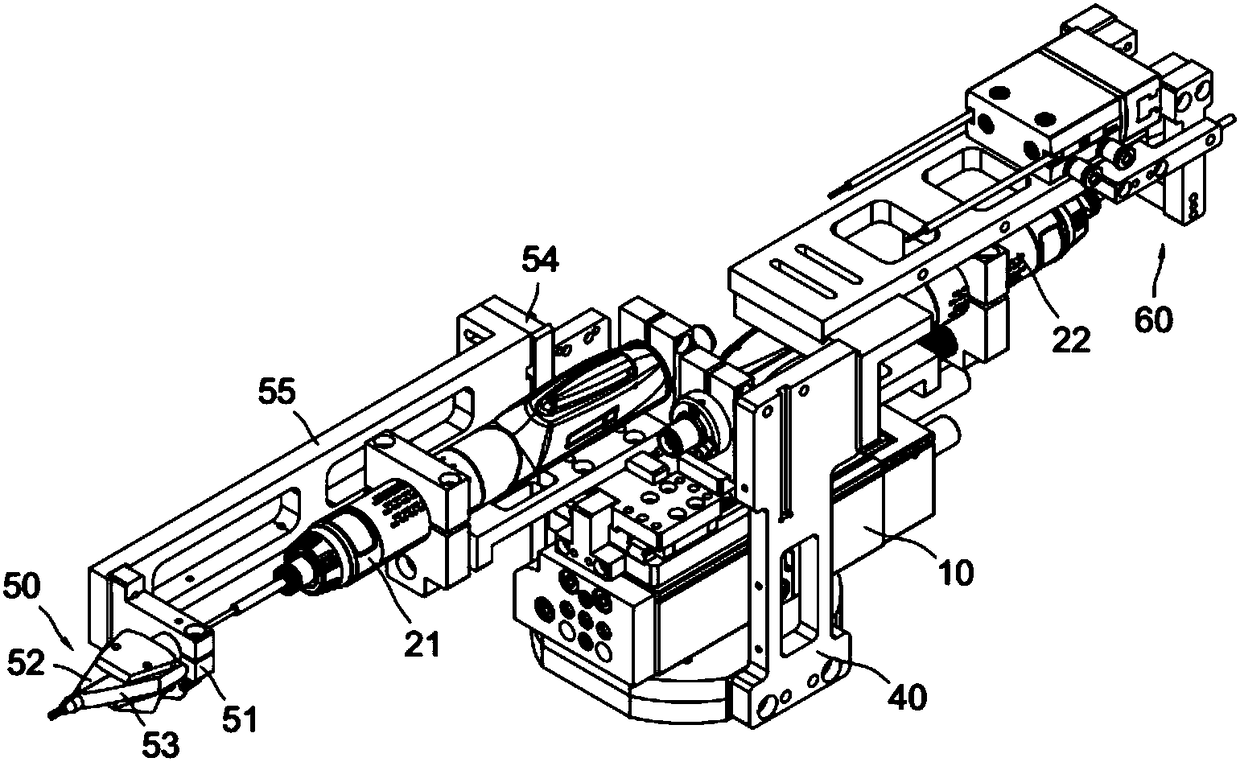

[0029] combine Figure 1 to Figure 4 , a two-way locking mechanism, including two locking tools installed on the driving mechanism, and the moving directions of the two locking tools are opposite when they work. The two locking tools are respectively a first locking tool and a second locking tool.

[0030] combine Figure 3 to Figure 6 , the drive mechanism includes a cylinder 10 mounted on the frame 40, a base plate 14 mounted on the cylinder piston, a first slide rail 15 and a second slide rail 16 mounted on the base plate, and slidingly fitted on the first slide rail The first sliding block 11 and the second sliding block 12 slidingly fitted on the second sliding rail, the first locking tool 21 is installed on the first sliding block, and the second locking tool 22 is installed on the second sliding block, A telescopic spring 13 is arranged between the first slider and the second slider. A first stopper 17 and a second stopper 18 are arranged on the base plate, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com