Caterpillar type ramie combined harvester

A combine harvester, crawler type technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of low efficiency of ramie peeling, achieve strong skin and bone separation ability, high rate of fresh stem peeling, peeling The effect of high net rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

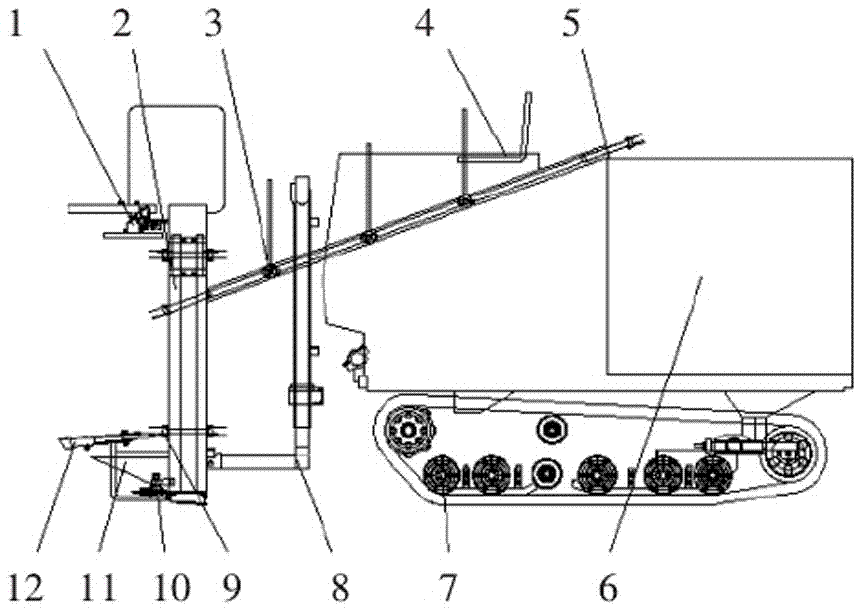

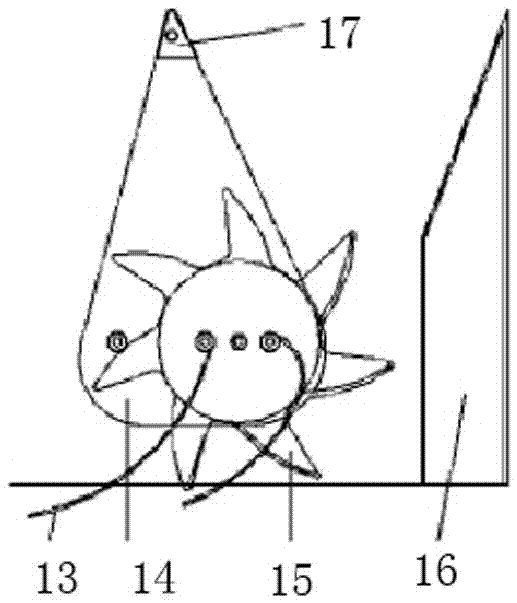

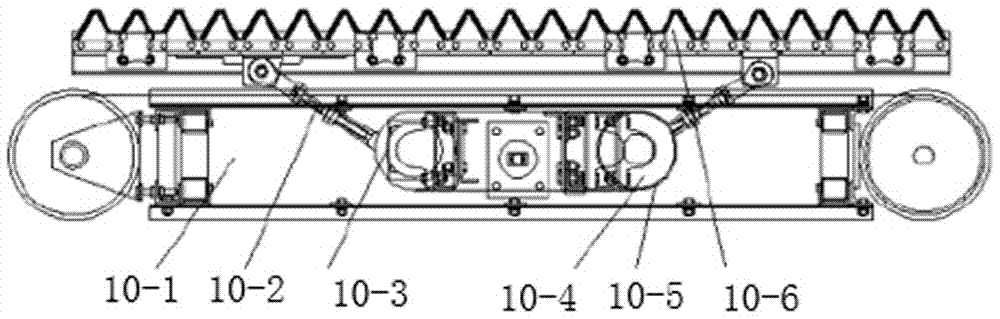

[0023] exist figure 1 Medium, including upper reel, header frame, longitudinal forced conveying device, driver's seat, longitudinal conveying chain, straw collecting box, chassis, suspension frame, transverse conveying device, cutter transmission device, grain divider, lower support grain harvester, adjust the height of the movable frame in the header frame so that the upper grain reel (1) device and the upper chain conveying device are at the same height as the hemp stalk; the grain divider (11) and the lower grain lifter (12) will The hemp stalks within the width are separated from both sides and lifted up; the double-moving knife cutting transmission device (10) cuts the hemp stalks and sends them to the horizontal conveying device (9) by the reeling star wheel; the horizontal conveying device composed of three sets of chains The device (9) transports the cut hemp stalks to the longitudinal forced conveying device (3), and then the longitudinal forced conveying device (3) s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com