Roller type automatic bread and steamed bun machine

A fully automatic, steamed bun machine technology, applied in the direction of mixing/kneading with vertical installation tools, cooking utensils, household utensils, etc., to achieve the effect of convenient cleaning and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

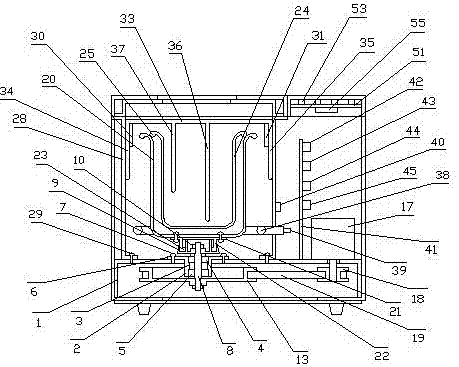

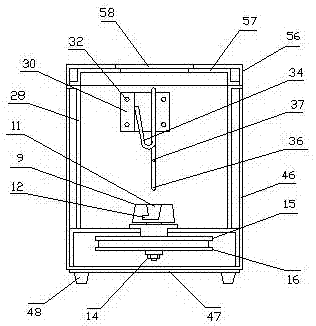

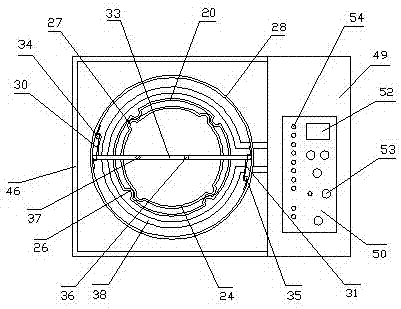

[0011] Further description below in conjunction with accompanying drawings.

[0012] exist figure 1 , figure 2 and image 3Among them, the drum-type automatic bread and steamed bread machine is equipped with a bread and steamed bread body, and the bread and steamed bread body is equipped with a movement chassis 1, the movement chassis is a box cover type, and the left side of the movement chassis is provided with a coupling installation hole , the circumference of the mounting hole is provided with 4 equally divided coupling nut holes, the lower coupling is installed in the coupling mounting hole, the lower coupling is provided with a bearing frame 2, and the inner circle of the bearing frame is formed with a blocking platform 3 to block An upper bearing 4 is installed on the upper end of the platform, and a lower bearing 5 is installed on the lower end of the blocking platform. A lower flange 6 is formed on the upper end of the bearing frame, and the circumference of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com