Device and method for producing zinc powder by using alcohol-based fuel

A technology of alcohol-based fuel and zinc powder, which is applied in the field of zinc powder production equipment, can solve problems such as the use of zinc powder furnaces that have not been seen, and achieve the effects of good flue gas radiation performance, anti-oxidation, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

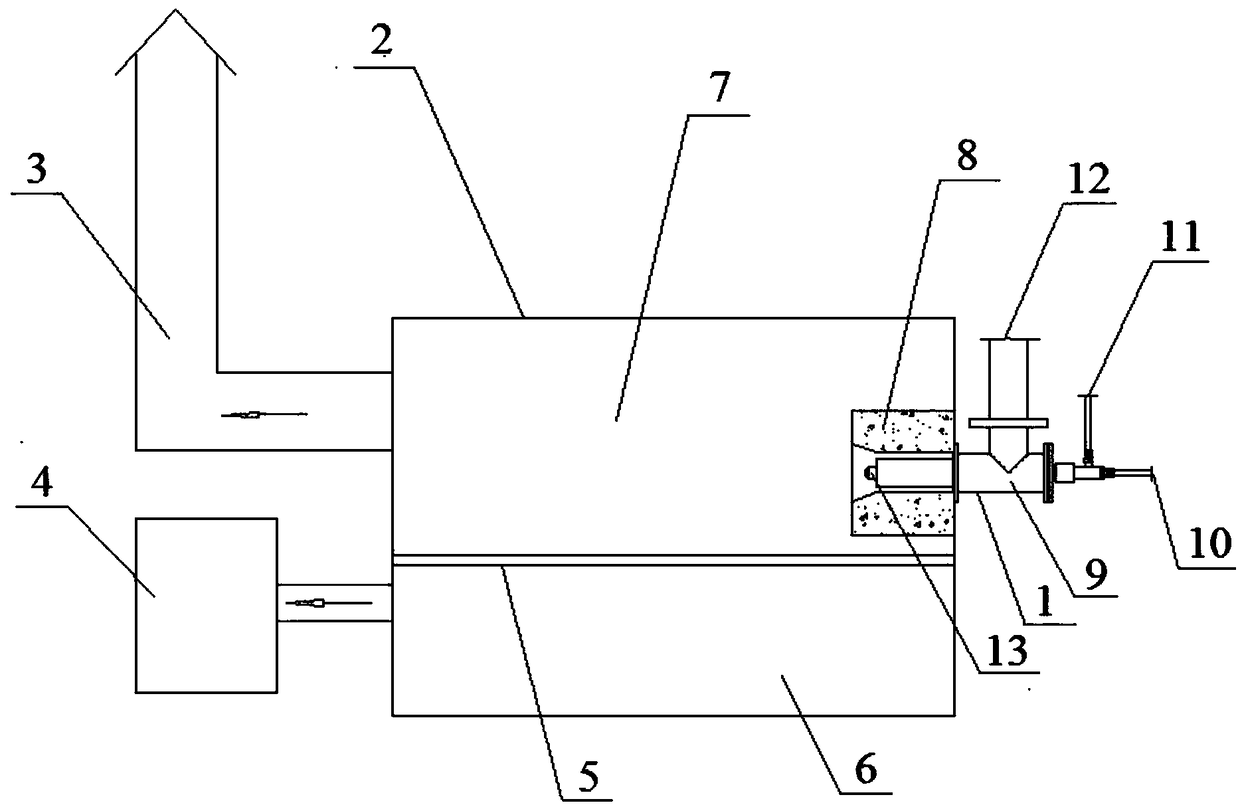

[0031] like figure 1 Shown, a kind of device that utilizes alcohol-based fuel to produce zinc powder of the present invention comprises alcohol-based fuel combustion system 1, zinc powder furnace 2, smoke exhaust system 3 and zinc powder collecting device 4, and zinc powder furnace 2 interior is arranged by horizontal The flame barrier 5 is divided into a melting evaporation pool 6 and a combustion chamber 7, one side of the melting evaporation pool 6 is connected to the zinc powder collection device 4; one side of the combustion chamber 7 is connected to the alcohol-based fuel combustion system 1, and the other side is connected to the smoke exhaust system 3; The alcohol-based fuel combustion system 1 includes a burner brick 8, a burner 9 arranged in the passage of the burner brick 8, and an alcohol-based fuel pipeline 10 connected to the fuel burner 9, a compressed air pipeline 11 and an air supply pipeline 12, and an installation It is composed of various valves on the abov...

Embodiment 2

[0039] The present invention adopts the method that the device described in embodiment 1 produces zinc powder, comprises the following steps:

[0040] (1) Add alcohol-based fuel (the volume ratio of methanol, ethanol and butanol is 5:1:1) into the burner 9 through the alcohol-based fuel pipeline 10, and use 0.4MPa compressed air to carry out pressure atomization. The pipeline 12 is used for air supply combustion, and the pressure of the air supply is 1KPa, so as to ensure the alcohol-based fuel is completely burned and avoid carbon deposition and other problems. The temperature of the burner brick 8 located in the combustion chamber 7 is 1200°C;

[0041] (2) Add zinc raw material through the zinc ingot feeding port, the zinc ingot in the zinc powder furnace 2 is heated and melted to generate zinc vapor, and the zinc vapor enters the zinc powder collecting device 4 through the channel provided on the side of the melting evaporation pool 6, and is cooled form zinc dust;

[0042...

Embodiment 3

[0044] The present invention adopts the method that the device described in embodiment 1 produces zinc powder, comprises the following steps:

[0045] (1) Add alcohol-based fuel (the mass ratio of methanol, ethanol and butanol is 6:2:2) into the burner 9 through the alcohol-based fuel pipeline 10, and use 0.6MPa compressed air to carry out pressure atomization. The pipeline 12 is used to supply air for combustion, and the pressure of the air supply is 1.5KPa, so as to ensure the complete combustion of the alcohol-based fuel and avoid problems such as carbon deposition. The temperature of the burner brick 8 located in the combustion chamber 7 is 1250°C;

[0046] (2) Add zinc raw material through the zinc ingot feeding port, the zinc ingot in the zinc powder furnace 2 is heated and melted to generate zinc vapor, and the zinc vapor enters the zinc powder collecting device 4 through the channel provided on the side of the melting evaporation pool 6, and is cooled form zinc dust;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com