A kind of glass writing board and its manufacturing method

A manufacturing method and writing board technology, applied to reusable writing boards, lighting devices, printing, etc., can solve problems such as lack of three-dimensional sense, inability to write, and inability to meet various needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

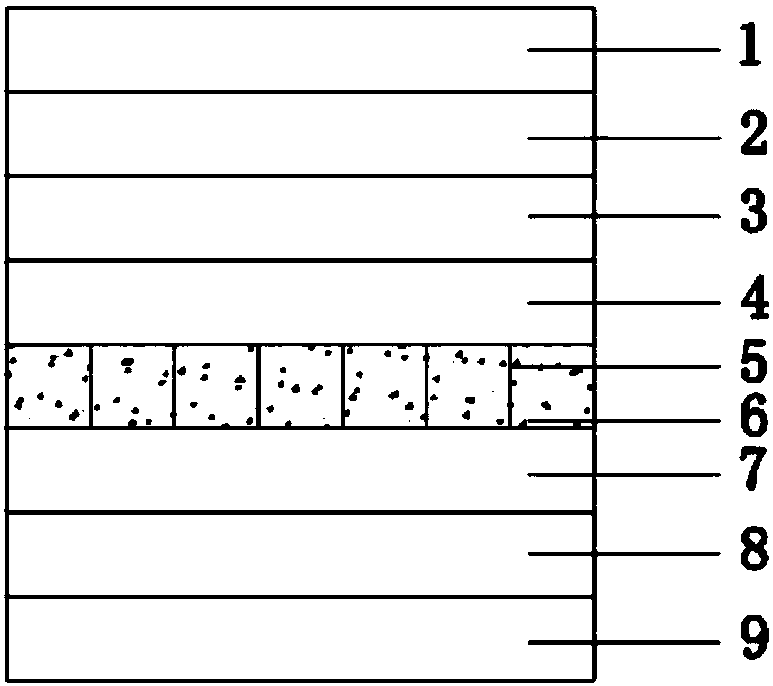

[0025] The glass writing board is based on glass 1, and an electroplated conductive layer 2 is provided on the lower surface of the glass 1, and an adhesive layer 3 of a UV adhesive layer is arranged under the conductive layer, and an upper electrically controlled magnetic plate is arranged on the lower surface of the adhesive layer 3. 4. The lower surface of the upper electrically controlled magnetic plate 4 is provided with a porous magnetic powder storage plate 5, and a magnetic powder 6 is provided inside the porous magnetic powder storage plate 5, and a lower electrically controlled magnetic soft plate is provided on the back of the porous magnetic powder storage plate 5 7. An illuminating board 8 made of LEDs is provided on the lower electronically controlled magnetic soft board 7 .

[0026] After the overall production is completed, assemble with the housing 9 or adhesives.

[0027] The UV adhesive layer is a mixture of varnish coated on the conductive glass layer 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com