Laminar airfoil suitable for general-purpose aircraft and with focus on cruise characteristic

A cruising characteristic, laminar flow wing technology, applied in the directions of wings, aircraft parts, wing shapes, etc., can solve the problem of lack of research on multi-working conditions performance, and achieve the effects of high lift-to-drag ratio, high lift, and high cruise efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

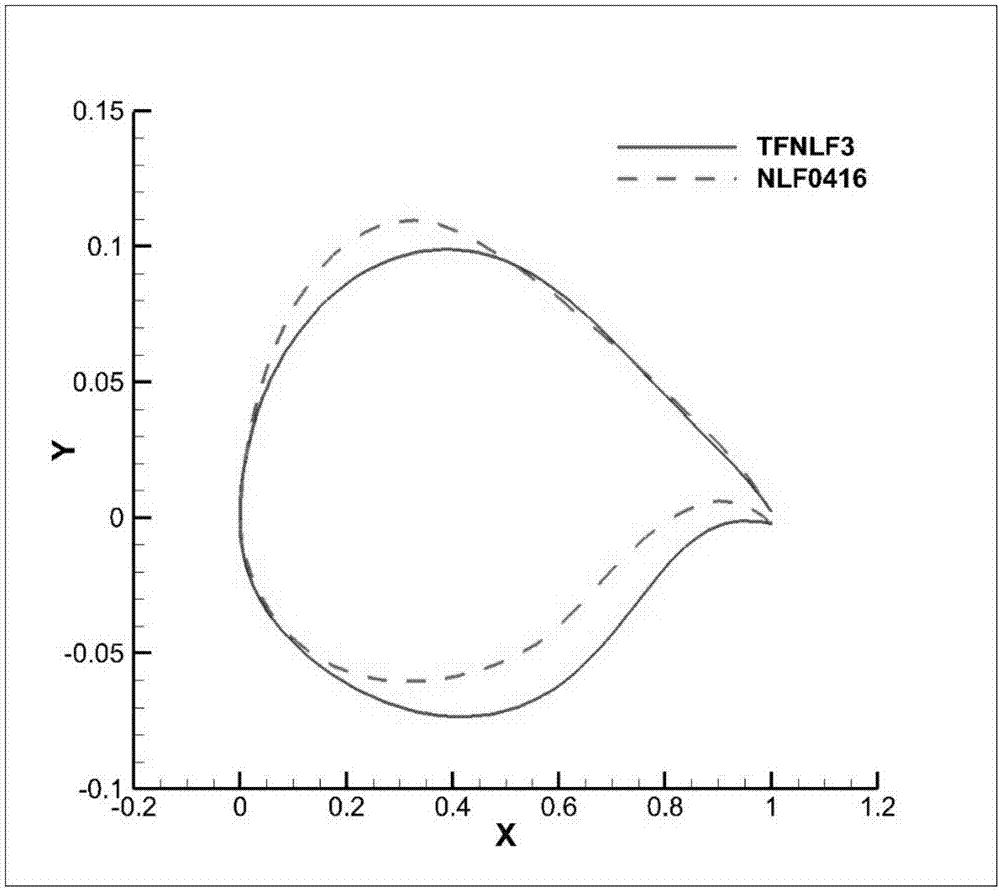

[0039] The object of the invention is to propose a laminar flow airfoil suitable for general-purpose aircraft, which pays more attention to the cruising characteristics of the airfoil while meeting the performance design requirements.

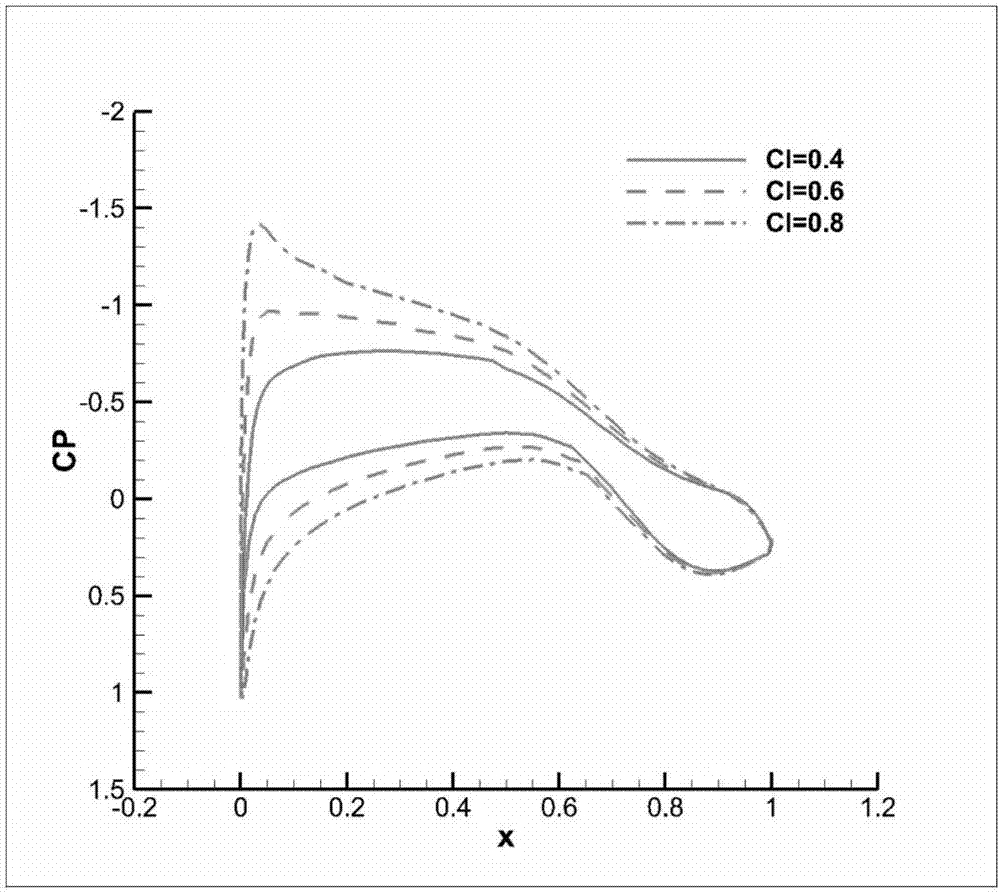

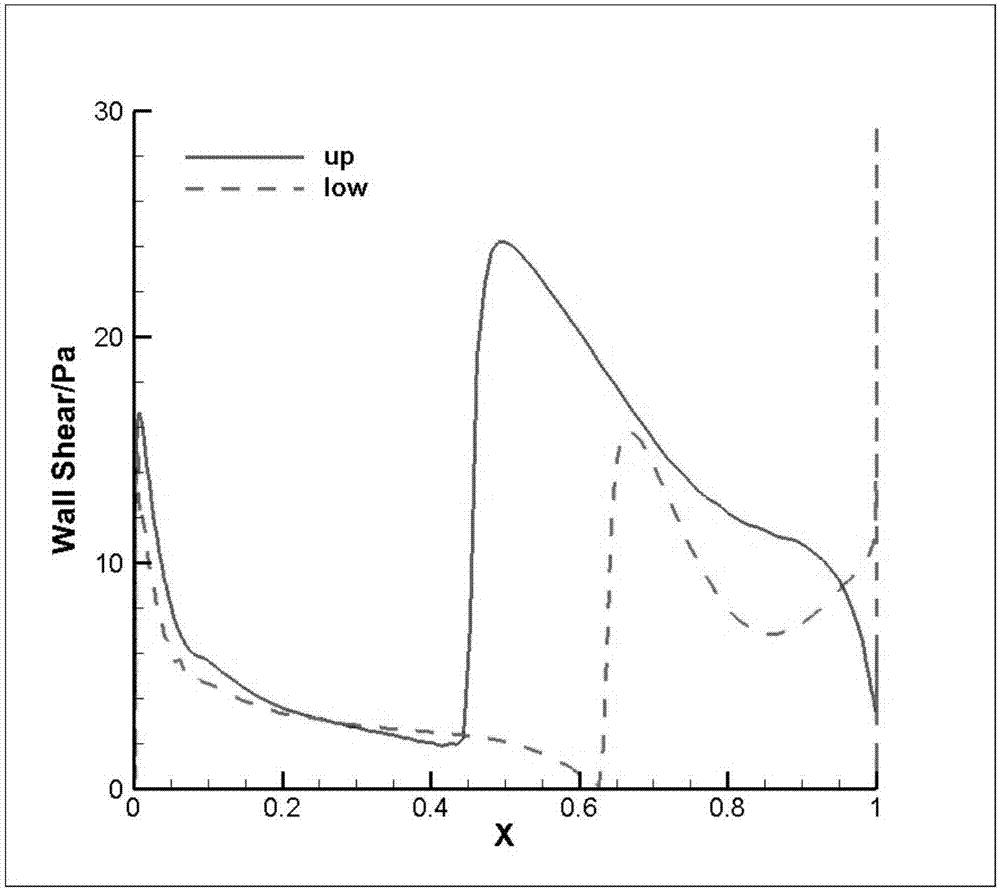

[0040] Through the use of advanced airfoil design and optimization technology, the airfoil can have a higher lift-to-drag ratio at a lower design lift coefficient, lower flight Mach number and lower flight Reynolds number, thereby improving cruise efficiency . In view of the fact that the cruising and climbing states are dominated by laminar flow, the airfoil design is carried out according to the idea of emphasizing the cruising characteristics, and the index requirements are:

[0041] 1. The length of the laminar flow zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com