Fluorescent ceramic used for illumination or display, and preparation method thereof

A technology of fluorescent ceramics and fluorescent powder, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of low cost, decreased luminous efficiency, yellowing, etc., and achieve the effect of stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

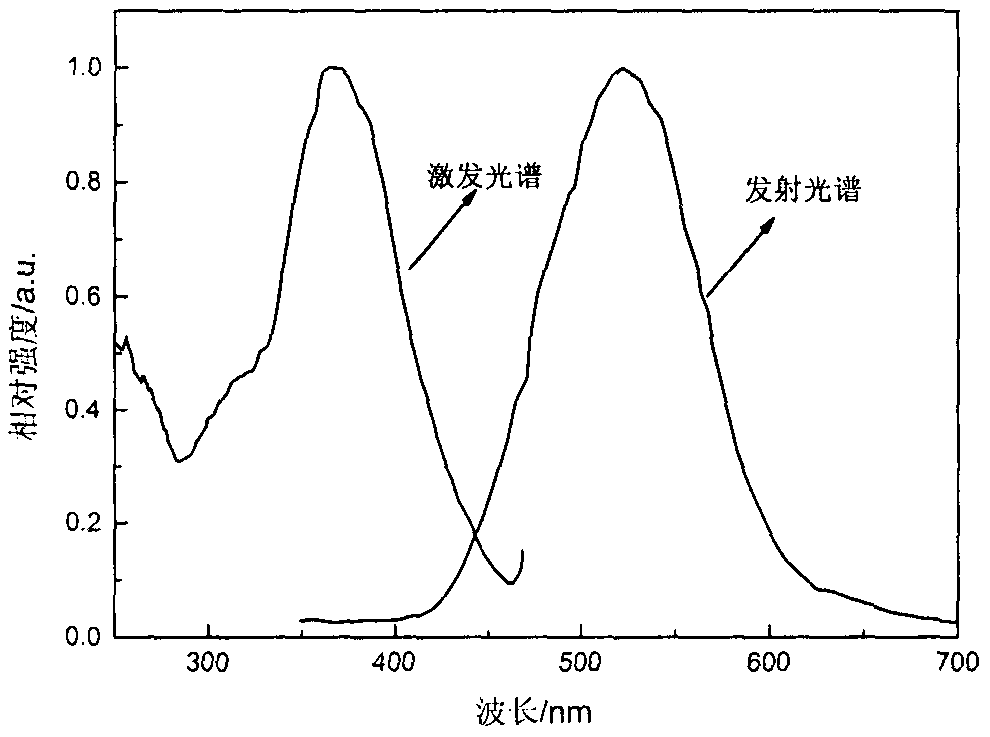

Image

Examples

Embodiment 1

[0018] A. Preparation of aluminosilicate phosphors: according to the chemical formula (Ca 0.3 Mg 0.7 ) 0.8 Al 2 Si 2 O 8 : 0.2Eu 2+ The ratio of each element in the MgCO 3 , CaCO 3 , Al 2 O 3 , SiO 2 and Eu 2 O 3 As a raw material, the weighed raw materials are mixed uniformly, and ball-milling is carried out. The ball-milling time is 3 hours, and the ball-milling speed is 120 rpm; High temperature calcination is carried out, the temperature is 1250 ° C, and the time is 8.5 hours. After the calcination is completed, when the temperature of the high temperature solid-phase furnace is lowered to room temperature, the furnace is opened, the materials are taken out, pulverized and sieved, and the desired aluminosilicate fluorescence can be prepared. pink;

[0019] B. Preparation of fluorescent ceramics: According to the mass ratio of ceramic raw material powder, sintering aids and aluminosilicate phosphors in fluorescent ceramics, respectively 75%, 3% and 22%, the mat...

Embodiment 2

[0021] A. Preparation of aluminosilicate phosphors: according to the chemical formula (Ca 0.4 Sr 0.6 ) 0.5 Al 2 Si 2 O 8 : 0.4Eu 2+ , 0.1Ce 3+ The ratio of each element in the SrCO is weighed 3 , CaCO 3 , Al 2 O 3 , SiO 2 , Eu 2 O 3 and CeO 2 As raw materials, the weighed raw materials were mixed uniformly, and ball milling was carried out. The ball milling time was 3.5 hours, and the ball milling speed was 120 rpm; High temperature calcination is carried out, the temperature is 1150 ° C, and the time is 9.5 hours. After the calcination is completed, when the temperature of the high-temperature solid-phase furnace is lowered to room temperature, the furnace is opened, the materials are taken out, pulverized and sieved, and the desired aluminosilicate fluorescence can be prepared. pink;

[0022] B. Preparation of fluorescent ceramics: According to the mass ratio of ceramic raw material powder, sintering aid and aluminosilicate fluorescent powder in fluorescent ce...

Embodiment 3

[0024] A. Preparation of aluminosilicate phosphors: according to the chemical formula (Ca 0.9 Sr 0.1 ) 0.3 Al 2 Si 2 O 8 : 0.25Eu 2+ , 0.45Ce 3+ The ratio of each element in the SrCO is weighed 3 , CaCO 3 , Al 2 O 3 , SiO 2 , Eu 2 O 3 and CeO 2As raw materials, the weighed raw materials were mixed uniformly, and then ball-milled. The ball-milling time was 3.5 hours, and the ball-milling speed was 120 rpm; 2 / H 2 High-temperature calcination is carried out in the formed reducing atmosphere, the temperature is 1350 ° C, and the time is 8 hours. After the calcination is completed, when the temperature of the high-temperature solid-phase furnace is lowered to room temperature, the furnace is opened, and the material is taken out, crushed and sieved to prepare the required aluminosilicate phosphors;

[0025] B. Preparation of fluorescent ceramics: According to the mass ratio of ceramic raw material powder, sintering aids and aluminosilicate phosphors in fluorescent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap