Liftable construction platform and assembly type building and construction method of liftable construction platform

A construction platform and prefabricated technology, which is applied in the direction of construction, building structure, housing structure support, etc., can solve the problems of difficulty in positioning components, high difficulty in positioning, and low installation efficiency, achieving wide coverage and shortening the construction period , The effect of high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

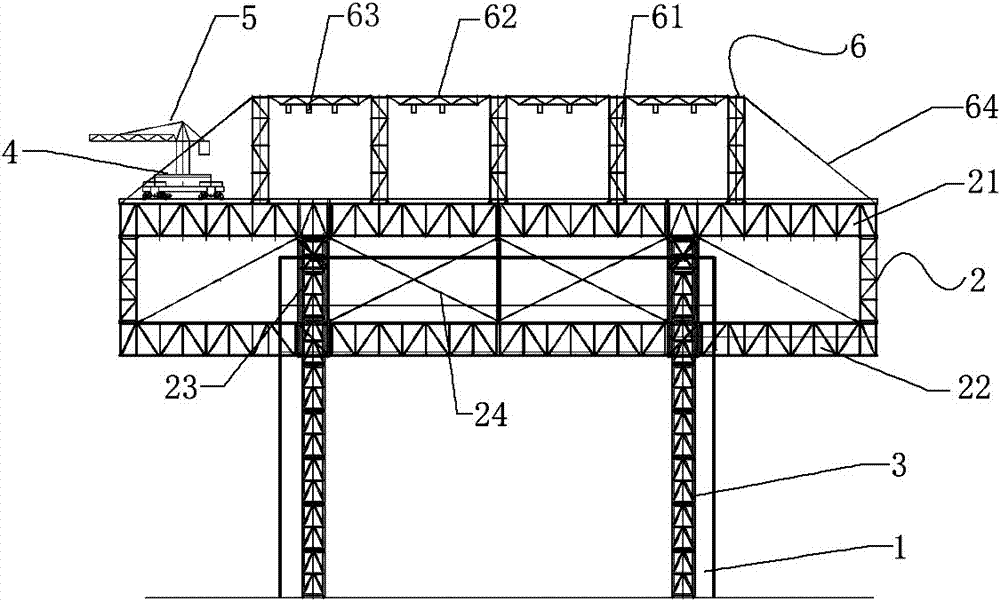

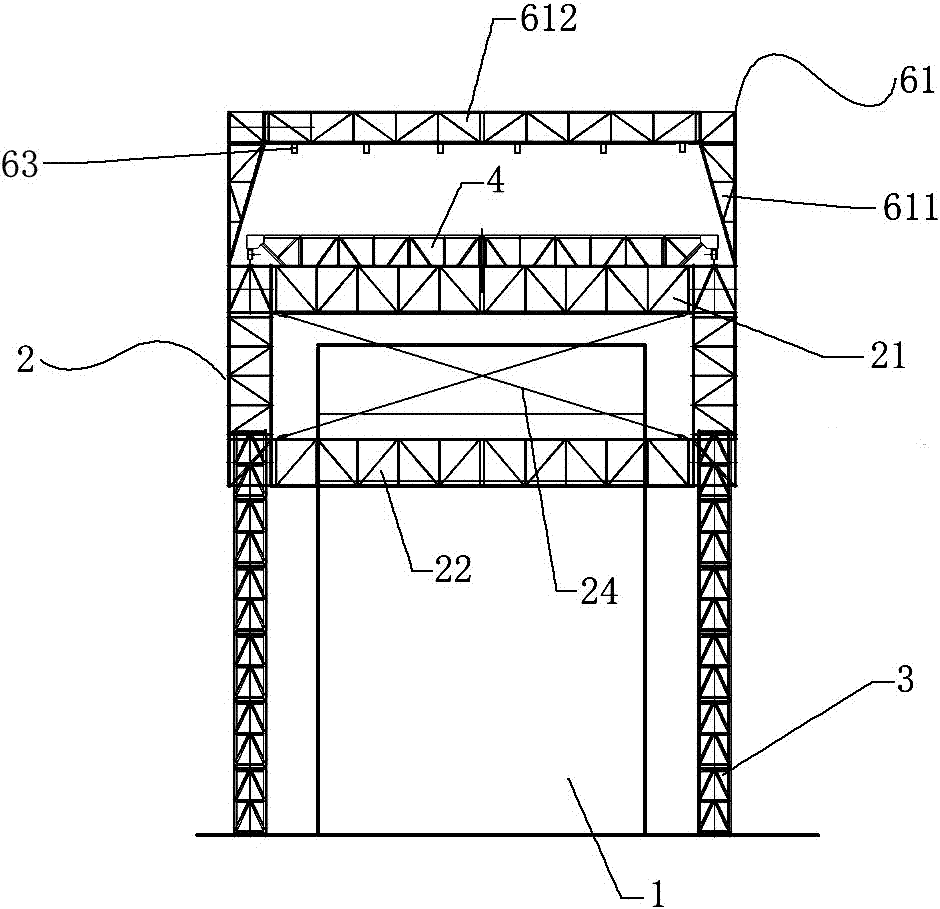

[0037] Such as figure 1 and figure 2 As shown, the liftable construction platform of the prefabricated building of the present invention includes a working platform 2 horizontally surrounding the periphery of the building 1, a mast 3 supporting the working platform 2, a bridge crane 4 located on the working platform 2, and a bridge crane installed on the bridge The concrete placing machine 5 on the crane 4 and the network frame 6 positioned at the top of the working platform 2 .

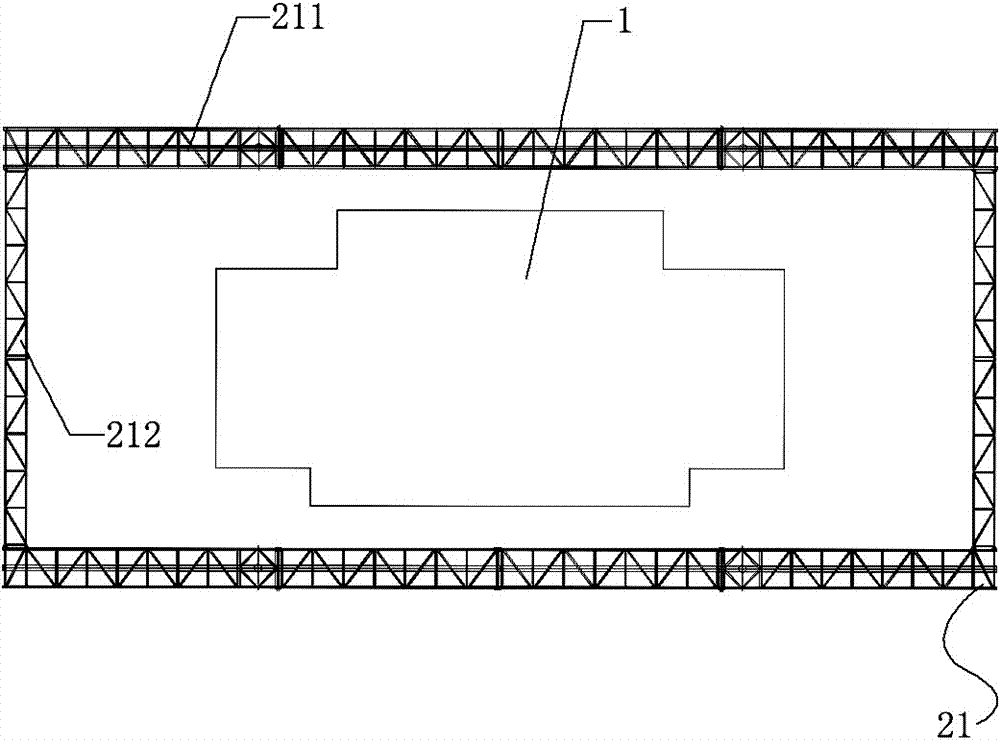

[0038] Such as image 3 and Figure 4As shown, the working platform 2 is spliced by truss components, and the longitudinal section of the truss components is rectangular; the working platform 2 includes an upper platform 21 and a lower platform 22 arranged in parallel and at intervals along the direction of the mast 3, and the upper platform 21 and the lower platform 22 are both It is a rectangular frame surrounded by long beams 211 and short beams 212; the lower platform 22 also includes reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com