Device and method for simulating complex crack sand paving

A technology for complex fractures and fractures, applied in the field of oil and gas field development and research, can solve the problems of inaccurate experimental data and failure to consider in-situ stress, etc., and achieve the effect of accurate experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

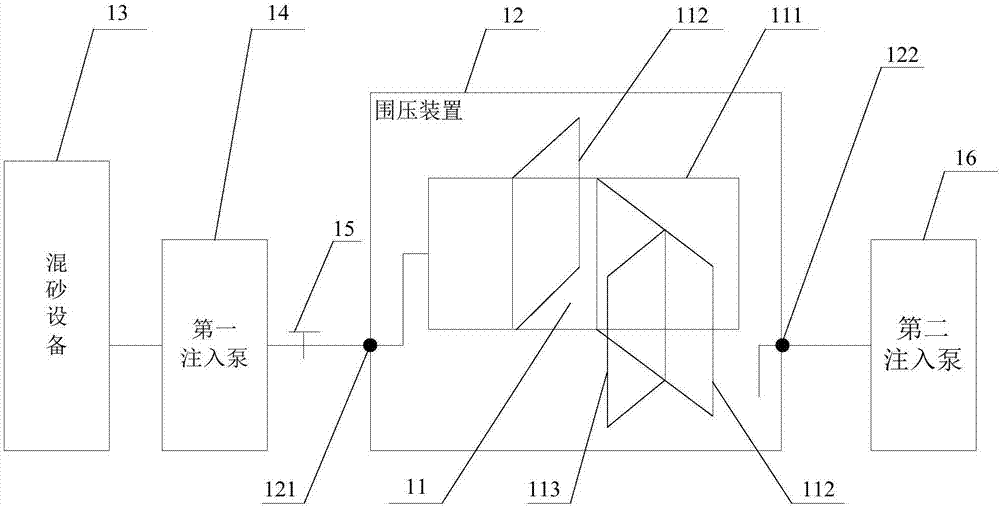

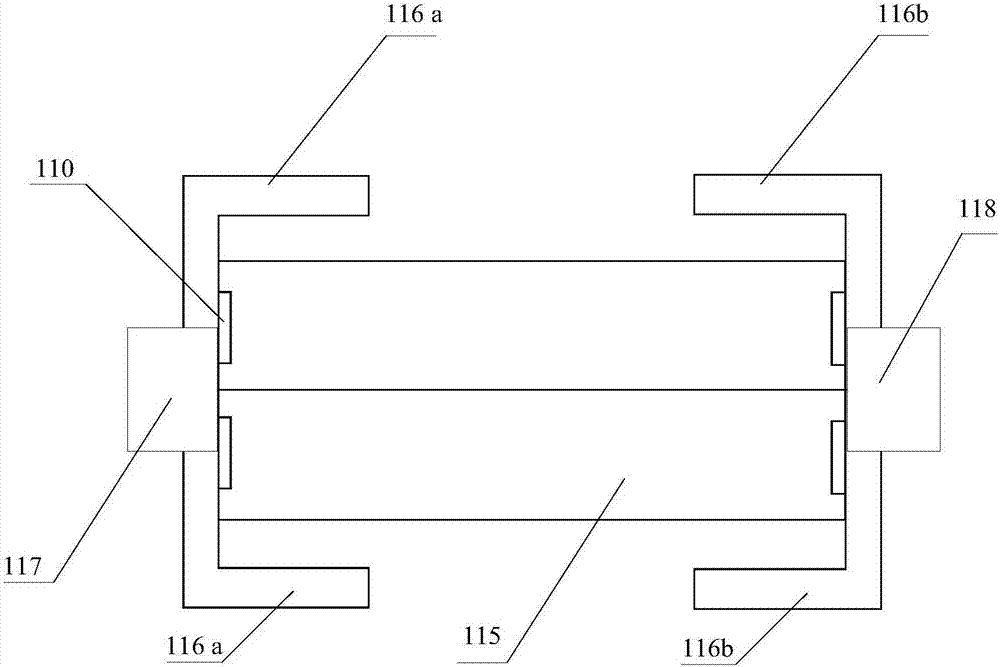

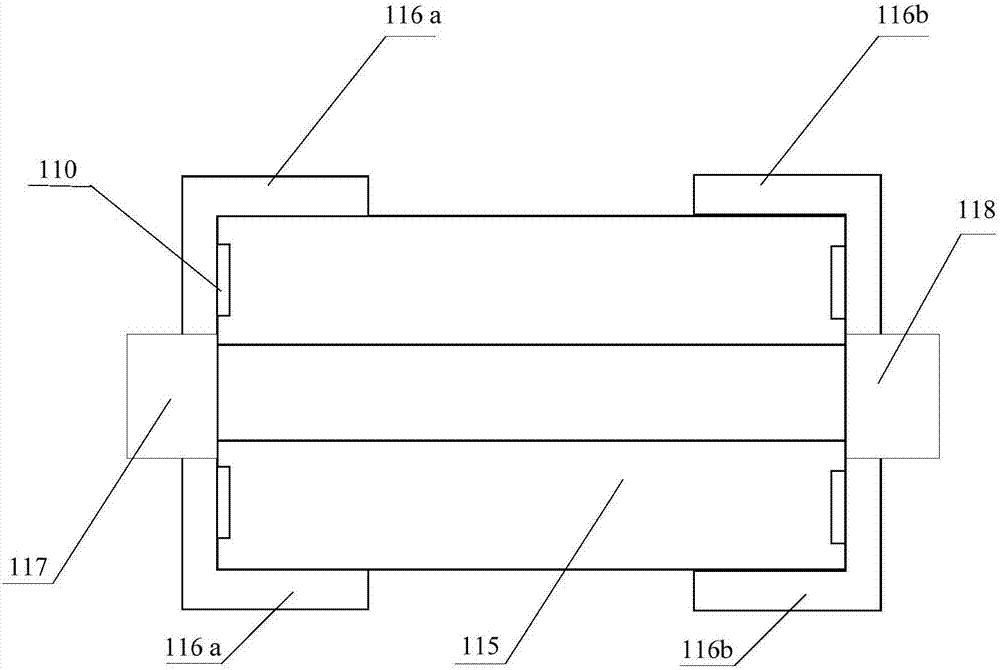

[0029] figure 1 Schematic diagram of the structure of the device for simulating complex fracture sanding provided by Embodiment 1 of the present invention. figure 2 A cross-sectional view of the main fracture assembly provided for Embodiment 1 of the present invention when the fracture is closed. image 3 A cross-sectional view of the main fracture assembly provided for Embodiment 1 of the present invention when the fracture is opened. The embodiment of the present invention aims at the fact that the shape of the cracked plate is fixed in the prior art, and the width of the cracked plate will not change during a simulated sand laying process; and the influence of the ground stress is not considered, which has great limitations and is different from the actual There is a big discrepancy in the situation, which leads to the inaccurate problem of the obtained experimental data, and a device for simulating complex fracture sanding is provided. Such as figure 1 As shown, the de...

Embodiment 2

[0042] Figure 4 A schematic diagram of the complex fracture simulation structure provided in Example 2. On the basis of the first embodiment above, as Figure 4 As shown, each of the crack components in the complex crack simulation structure 11 includes a plurality of inlet joints 117 and a plurality of outlet joints 118, the inlet joints 117 are evenly distributed along the length direction of the frame where they are located, and the outlet joints 118 are evenly distributed along the length direction of the frame where they are located. When carrying out the experiment, the output port of the first injection pump 14 is connected to a plurality of inlet joints 117 of the main fracture assembly through the second pipeline passing through the first port, and is distributed uniformly along the length direction of the frame. The multiple inlet joints 117 can be injected with liquid, which can realize the function of simulating a wellbore without setting up a simulated wellbore...

Embodiment 3

[0050] Figure 5 It is a schematic diagram of the complex fracture simulation structure provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiment one or embodiment two, as Figure 5 As shown, the complex crack simulation structure also includes at least one support rod 201, which is an adjustable length telescopic rod with locking parts, and the two ends of each support rod 201 are rotatably connected to the corresponding between two adjacent secondary split assemblies 202 and 203, or between two adjacent third-stage split assemblies rotatably connected. When the support rods 201 are locked, each of the support rods 201 rigidly connects two adjacent secondary crack components 202 and 203 , or rigidly connects two adjacent tertiary crack components.

[0051] In this embodiment, the support rod is connected to two adjacent crack surfaces through a direction-lockable universal joint, so that both ends of the support rod 201 are ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com