Ceramic quick opening valve element and production process thereof

A production process and valve core technology, applied in valve devices, mechanical equipment, engine components, etc., can solve the problems of easy slippage and fracture of plastic threads, difficult stainless steel processing, poor pressure resistance, etc., to reduce metal pollution, Good waterproof sealing, good expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

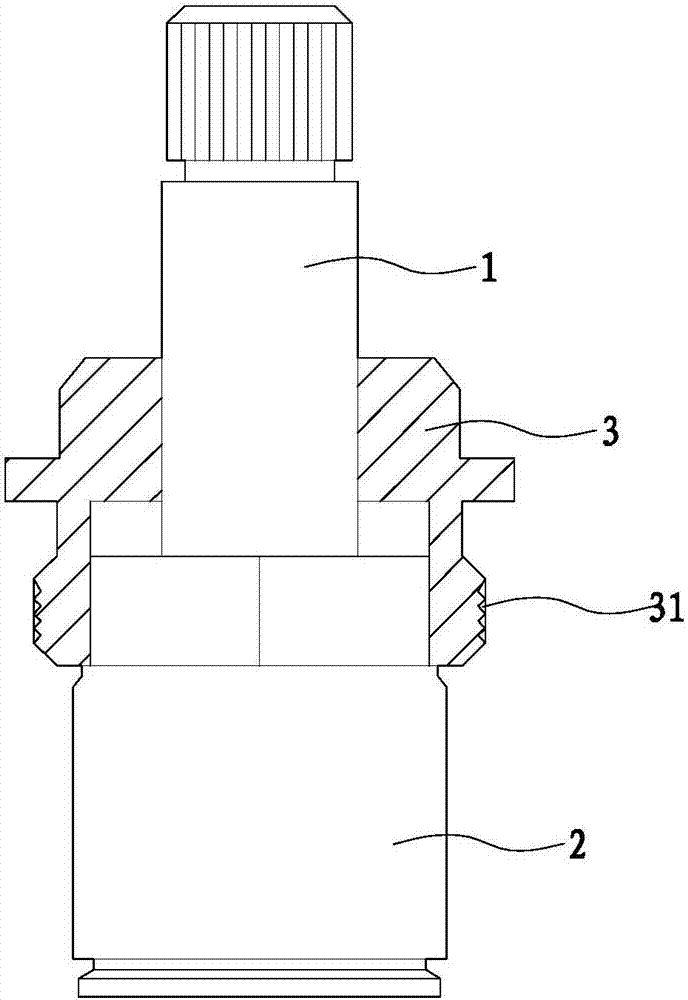

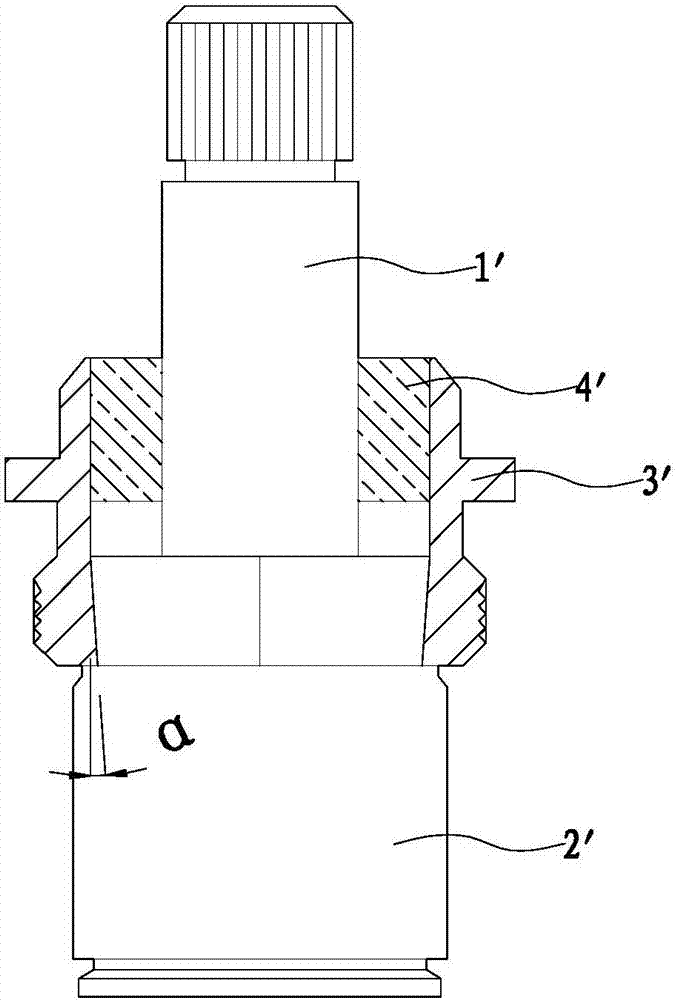

[0019] refer to figure 1 , the first embodiment provides a ceramic quick-opening valve core, including a housing and a valve core rod 1 installed in the housing, the housing includes a plastic valve core body 2, a metal valve core sleeve with a connecting portion 31 3. The metal valve core cover 3 is sleeved on the outside of the plastic valve core body 2, and the metal valve core cover 3 and the plastic valve core body 2 are integrally formed by injection molding. The metal valve core sleeve 3 is in interference fit with the plastic valve core body 2 . The part where the metal valve core sleeve 3 is attached to the plastic valve core body 2 is an inner hexagonal surface.

[0020] The part where the metal valve core sleeve and the plastic valve core body are bonded can also be other non-circular surfaces (such as square, rhombus, triangle, etc.) or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com