Liquid line transportation security system

A safety guarantee and liquid pipeline technology, which is applied in pipeline systems, gas/liquid distribution and storage, pipes/pipe joints/fittings, etc., can solve pipeline explosions, complex changes in bubble mixing and separation, and inability to separate liquids and gases. To achieve the effect of novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A liquid pipeline transportation safety assurance system of the present invention will be further described in detail below with reference to the drawings and embodiments.

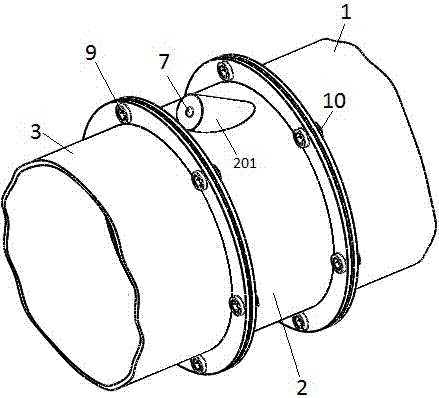

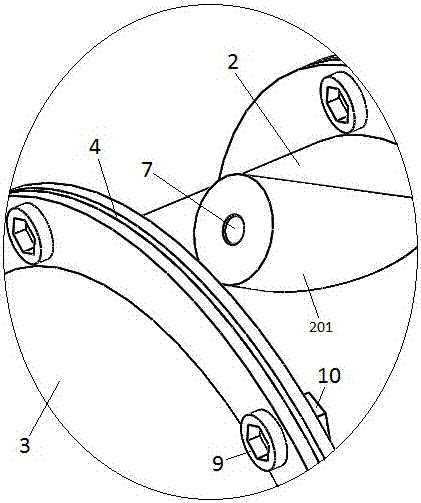

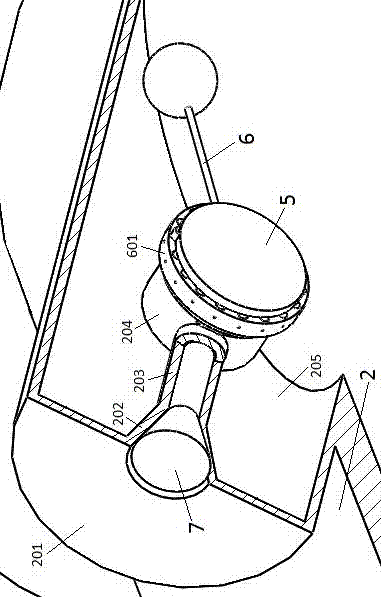

[0042] A liquid pipeline transportation safety assurance system, characterized in that it includes a liquid inlet pipe 1, an air outlet pipe 2, a liquid discharge pipe 3, a sealing ring 4, a rotating cover 5, a driving ball rod 6, a piston 7, a screw 8, a bolt 9, nut10.

[0043] Such as figure 1 , figure 2 , Figure 8 , Figure 9As shown, the liquid inlet pipe 1 and the liquid discharge pipe 3 are circular pipes, flanges are provided at both ends of the circular pipes, and bolt holes are provided on the flanges; the main body of the air outlet pipe 2 is a circular pipe , the diameter is the same as that of the liquid inlet pipe 1 and the liquid discharge pipe 3, flanges are also provided at both ends of the air outlet pipe 2, and bolt holes are also provided on the flanges; the sealing ring 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com