A group control system of ground source heat pump

A ground-source heat pump and ground-source side technology, which is applied in heat pumps, lighting and heating equipment, refrigeration safety arrangements, etc., can solve the problems of different unit life spans and unbalanced unit running time, etc., to achieve improved service life and accurate temperature Effect of controlling and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

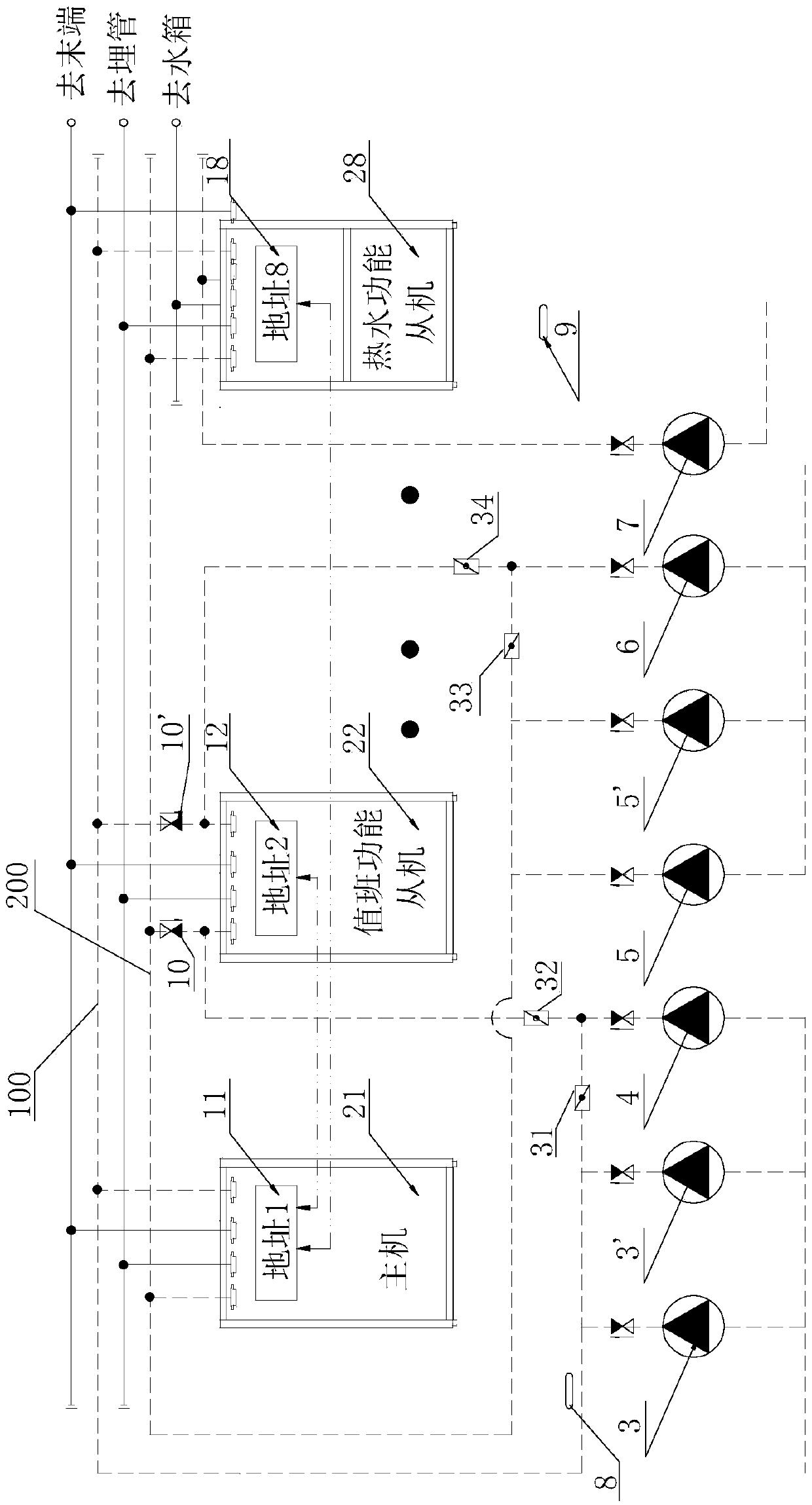

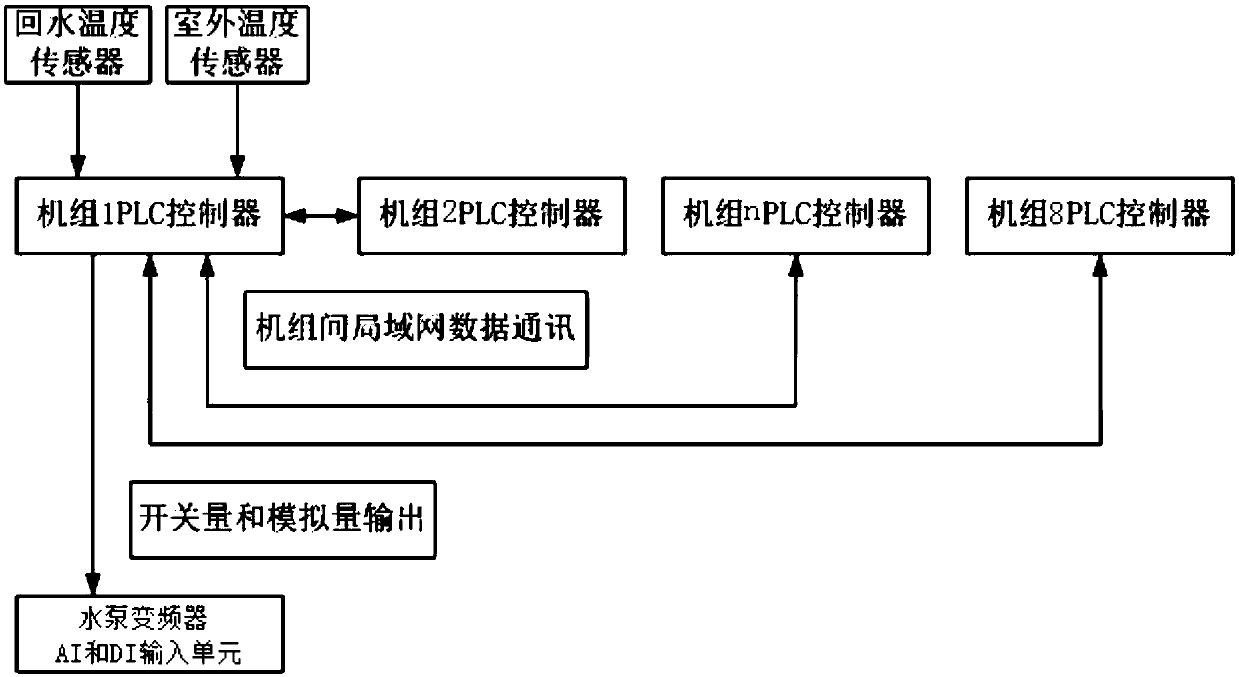

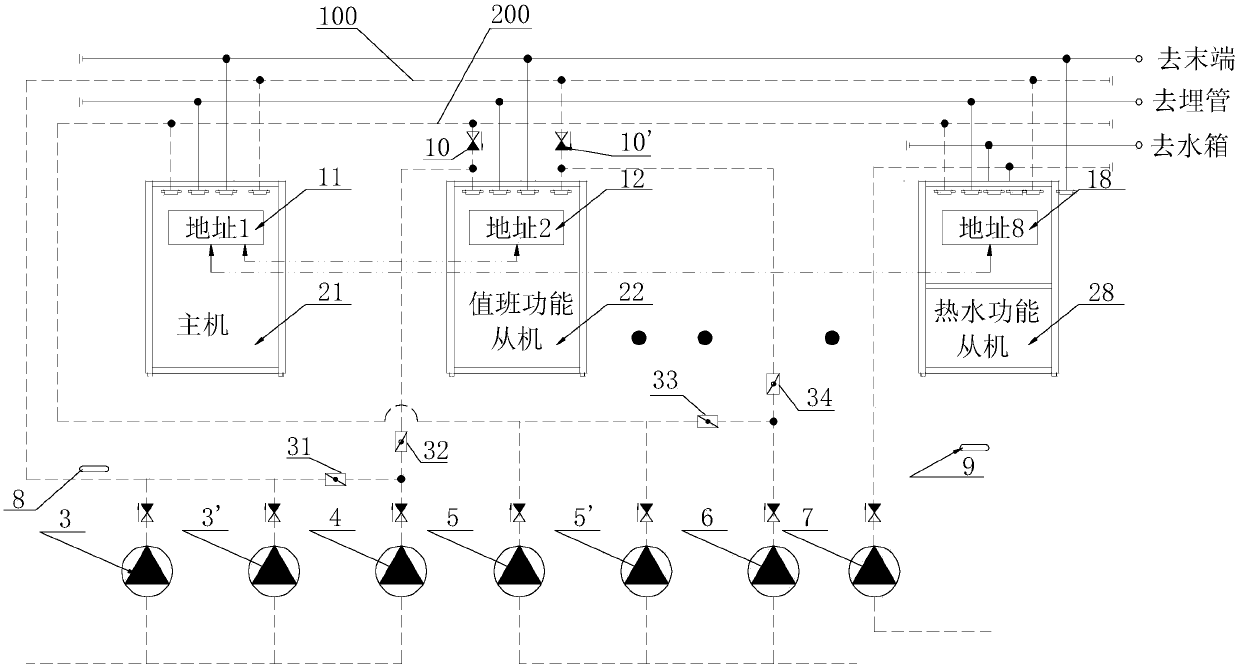

[0020] see figure 1 and figure 2 , a ground source heat pump group control system of the present invention includes multiple parallel ground source heat pump units, two user-side water pumps 3, 3', a user-side standby water pump 4 (user-side standby water pump), two ground Source side water pumps 5, 5', a ground source side backup water pump 6 (ground source side backup water pump), at least one hot water circulation pump 7, a return water temperature sensor 8 and an outdoor temperature sensor 9.

[0021] In this case, the maximum number of online ground source heat pump units is eight; the eight ground source heat pump units 21-28 are respectively connected to the user-side supply and return water main pipe 100 through the user-side water supply and return branch pipes, and the eight ground source heat pump units 21-28 The water supply and return main pipe 200 on the us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com