Operation method of voltage stabilizer electric heater

A technology of electric heaters and operating methods, applied in thermal reactors, nuclear power generation, non-uniform reactors, etc., can solve the problems of low comprehensive utilization rate, high failure rate of long-term group electric heaters, long-term group electric heaters and short-term group Problems such as unbalanced accumulative running time of electric heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

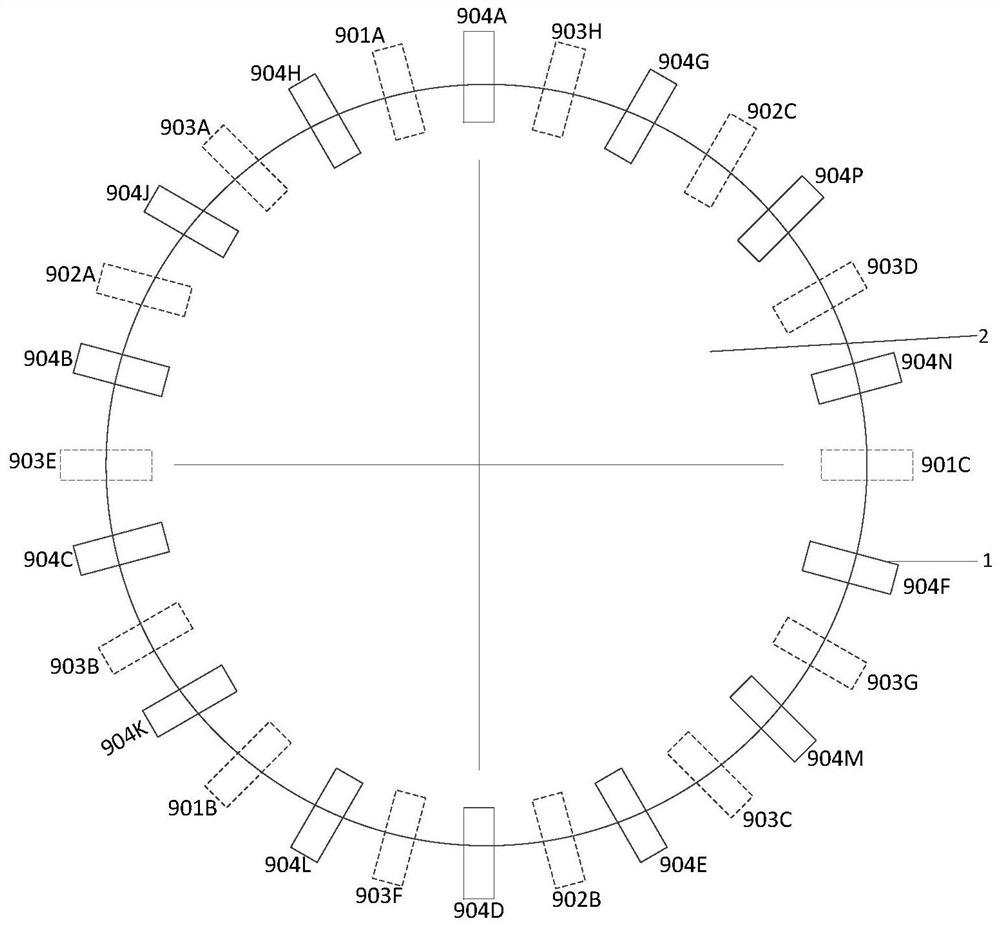

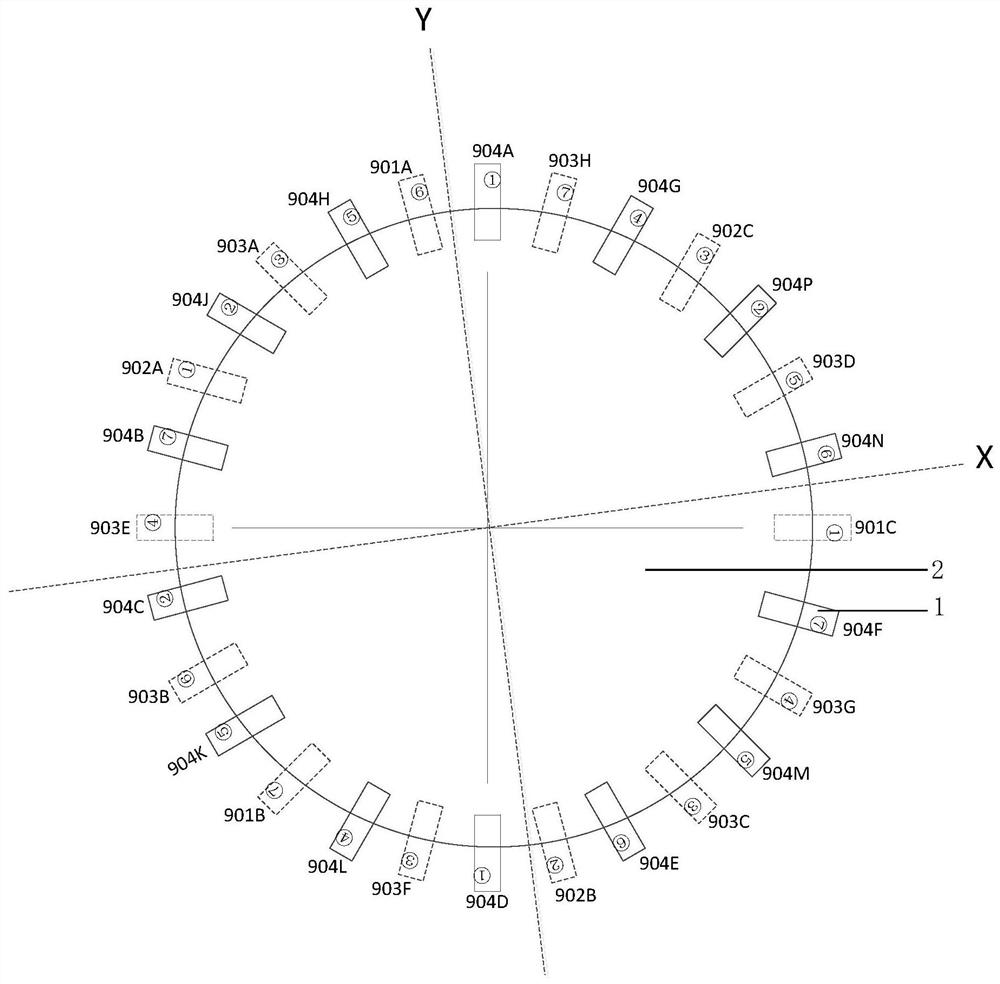

[0064] The voltage stabilizer is a cylindrical tank with a height of 13.48 meters and a diameter of 3 meters. There are 28 electric heaters in total. The voltage stabilizer electric heater is divided into two layers, and 14 of each layer are evenly distributed on the bottom of the voltage stabilizer. The lower layer is 1.5 meters from the bottom, and the upper layer is 2 meters from the bottom.

[0065] Such as image 3 As shown, in the plane space, the 28 voltage regulator electric heaters are divided into 4 sections by the mutually perpendicular X-axis and Y-axis, and each section has 7 voltage regulator electric heaters. The voltage regulator marked by the dotted line The electric heater is on the lower floor, and the voltage regulator electric heater marked by the solid line is on the upper floor.

[0066] Select one regulator electric heater for each interval, and the group is marked as "①" to form the first group. Select one voltage regulator electric heater for each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com