Virtual welding system and method

A virtual welding and weldment technology, applied in the field of virtual teaching, can solve the problems of poor safety and poor training effect, and achieve the effect of avoiding waste of materials, learning comprehensively, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

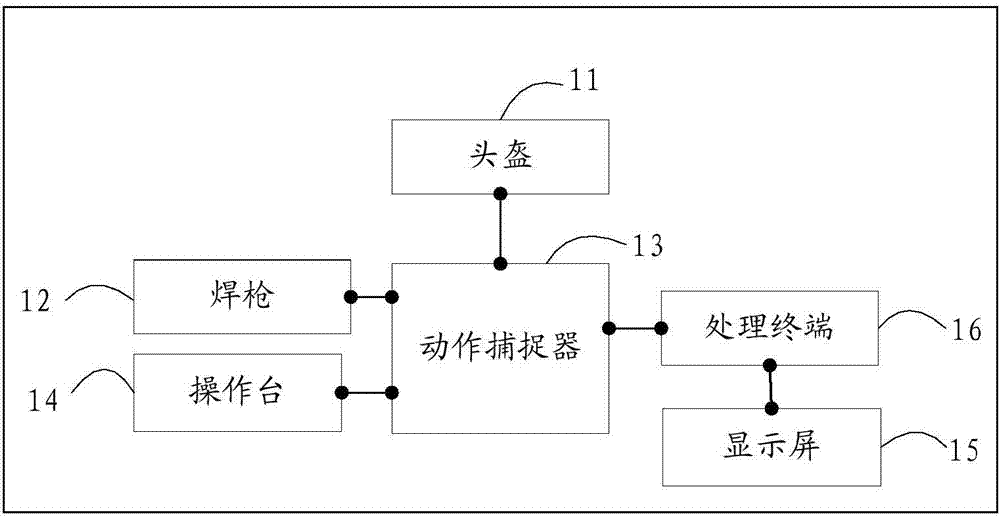

[0046] figure 1 A structural diagram of a virtual welding system provided by the first embodiment of the present invention is shown, and for convenience of description, only parts related to the embodiment of the present invention are shown.

[0047] The virtual welding system includes: helmet 11, welding torch 12, motion capture device 13, console 14, display screen 15 and processing terminal 16, wherein:

[0048] The operating table 14 is used to place real workpieces to be welded.

[0049] The motion capture device 13 is used to acquire the head pose data of the helmet 11 , the motion trajectory data of the welding torch 12 and the operation trajectory data of the real workpiece to be welded.

[0050] Specifically, the motion capture device 13 may include a space tracking locator. The space tracking locator is a value that can detect in real time a moving object relative to a fixed object in six degrees of freedom, that is, the position value on the X, Y, and Z coordinate...

Embodiment 2

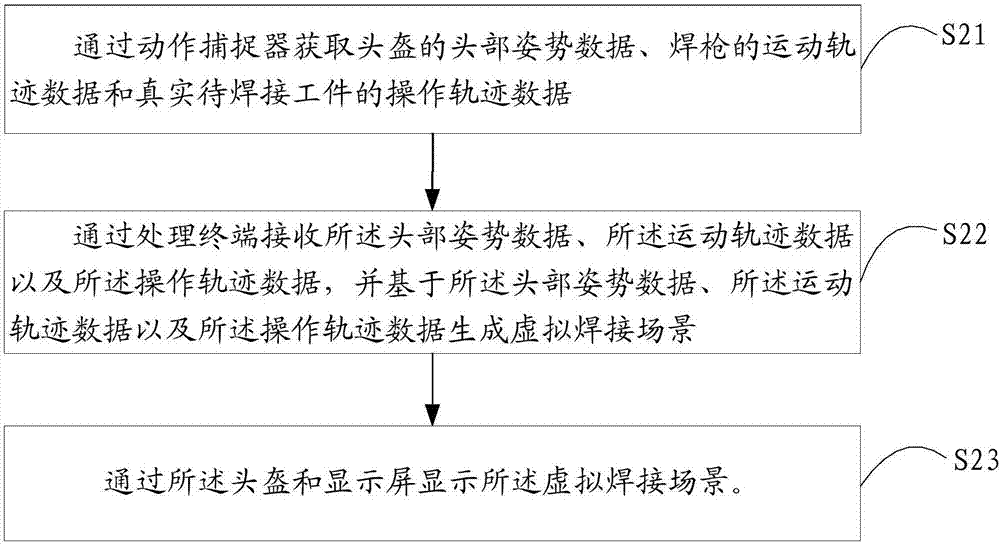

[0086] figure 2 It shows a flow chart of a virtual welding method provided by the second embodiment of the present invention, which is described in detail as follows:

[0087] Step S21, acquire the head posture data of the helmet, the motion trajectory data of the welding torch and the operation trajectory data of the real workpiece to be welded through the motion capture device.

[0088] Step S22, receiving the head posture data, the movement trajectory data and the operation trajectory data through the processing terminal, and generating a virtual welding scene based on the head posture data, the movement trajectory data and the operation trajectory data .

[0089] Step S23, displaying the virtual welding scene through the helmet and the display screen.

[0090] The virtual welding method in this embodiment adopts the virtual welding system described in Embodiment 1, and the specific content of Step S21 , Step S12 and Step S13 refers to Embodiment 1 and will not be repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com