Roller for rolling icecream wafers

A tool and ice cream technology, which is applied in applications, frozen desserts, and cardboard winding items, can solve the problems of edge area deformation and cone shape deformation of ice cream waffle cones, so as to prevent edge protrusion, reduce interaction, To ensure the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

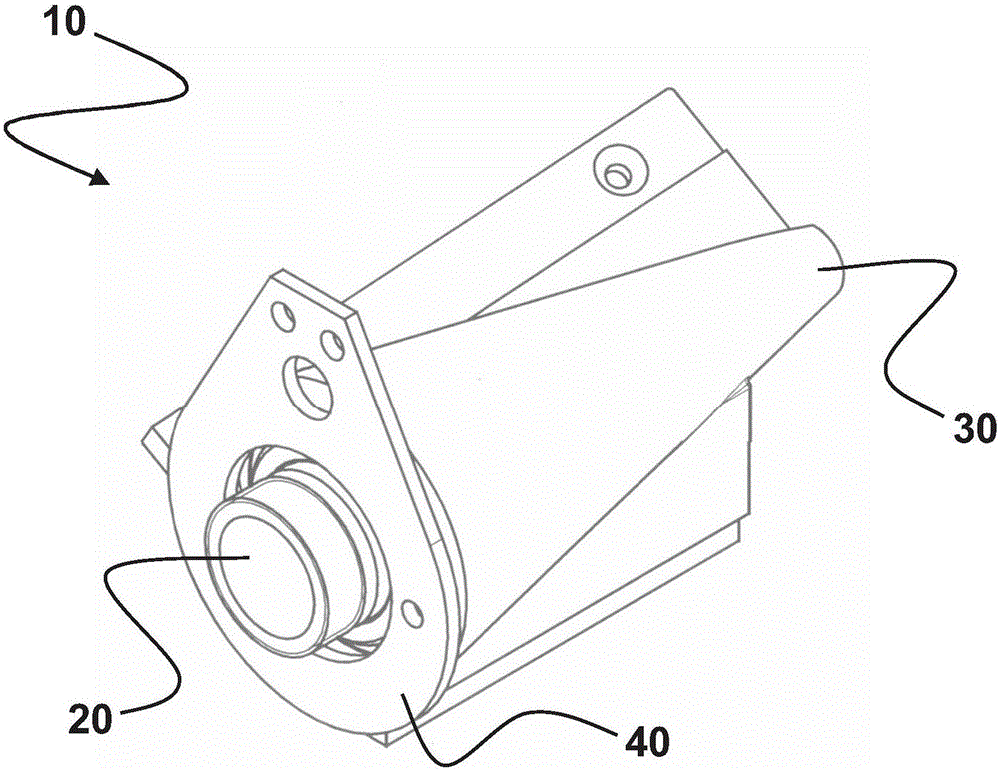

[0021] figure 1 A perspective view of a winding tool of a particularly preferred design according to the invention is shown.

[0022] The rolling tool 10 has a rolling sleeve 30 which receives the rolling mandrel 20 and whose opening can be sealed by a sealing plate 40 .

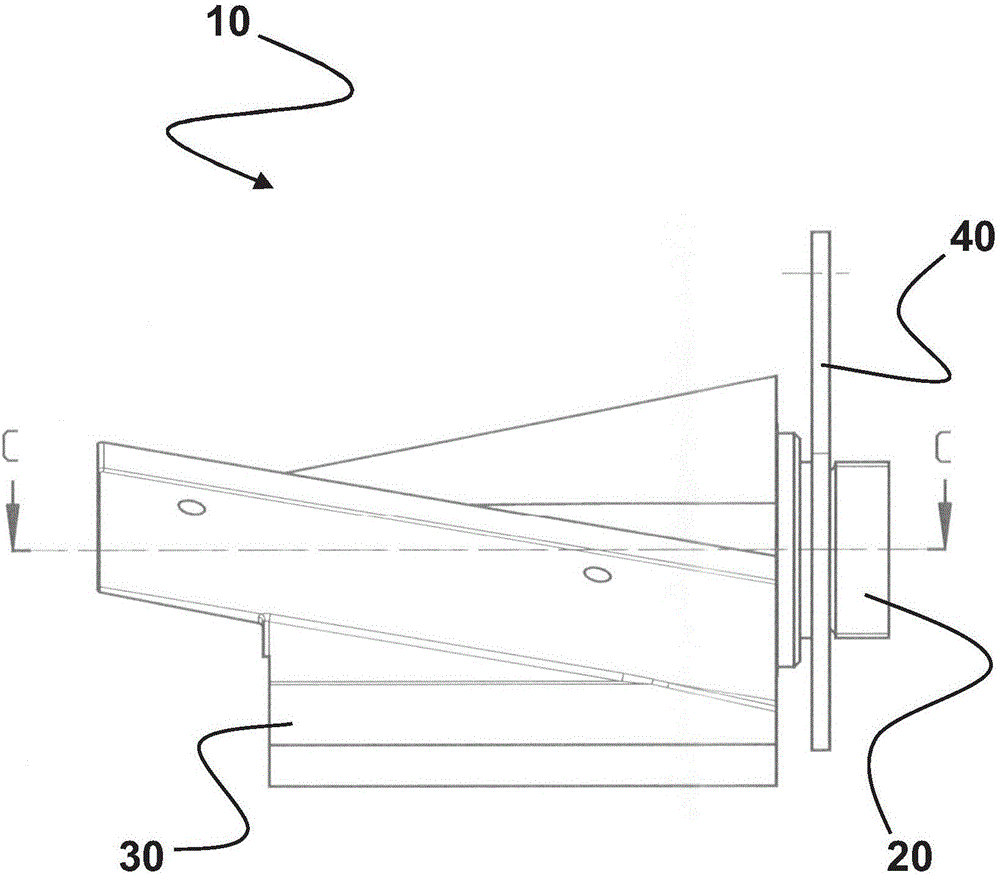

[0023] figure 2 shown in figure 1 A side view of the rolling tool 10 is shown in three-dimensional view, from which it can be seen that the rolling mandrel 20 is arranged through the central opening of the sealing plate 40 .

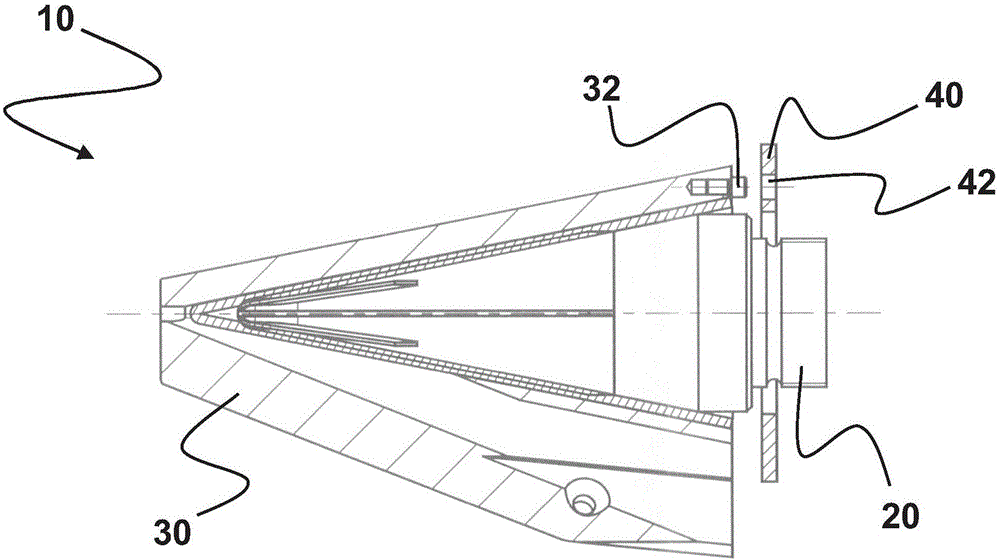

[0024] image 3 The pair along the line C-C is shown in the first working position figure 2 A cross-sectional view taken of the winding tool 10 shown in . In this first working position, the rolling mandrel 20 is completely received by the rolling sleeve 30 , wherein the sealing plate 40 does not perform a sealing function in this position.

[0025] However, an edge profile element 32 arranged on the winding sleeve 30 can be seen, which extends over the open end of the winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com