Method for extruding frozen camphene/silicon nitride body to prepare oriented porous silicon nitride ceramic

A technology for preparing silicon nitride ceramics and green bodies, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of preparing highly oriented porous silicon nitride ceramics that have not yet been disclosed, and achieve easy control of pore structure and ceramic quality. The effect of high porosity and uniform distribution of pore structure

Active Publication Date: 2015-11-25

西安晶科立芯半导体设备有限公司

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The prior art has not disclosed the preparation of highly oriented porous silicon nitride ceramics by extrusion of camphene / silicon nitride frozen body at room temperature

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 4

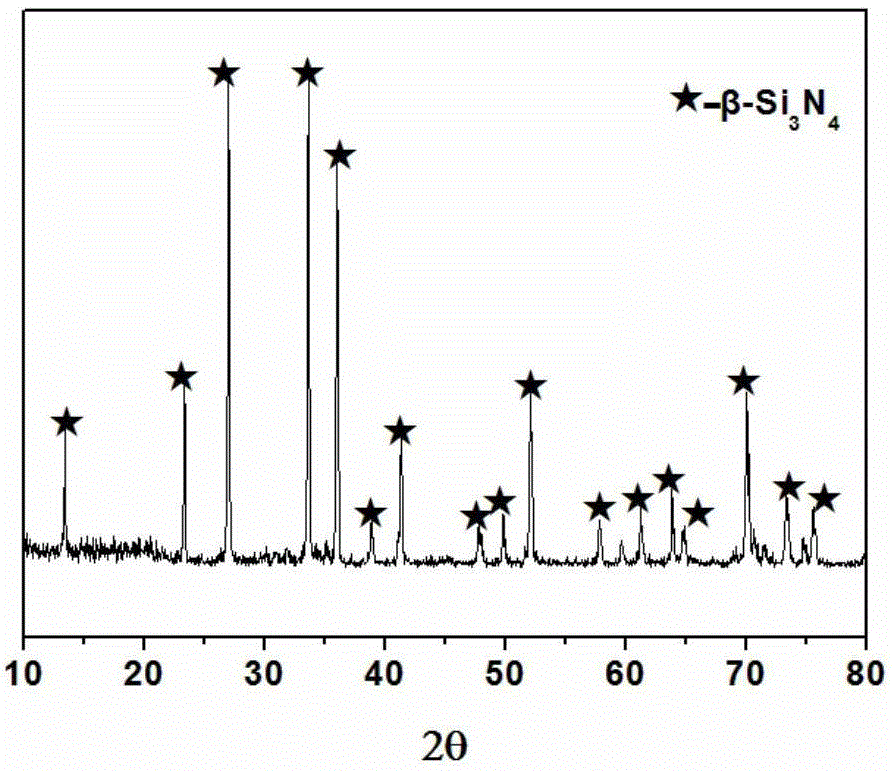

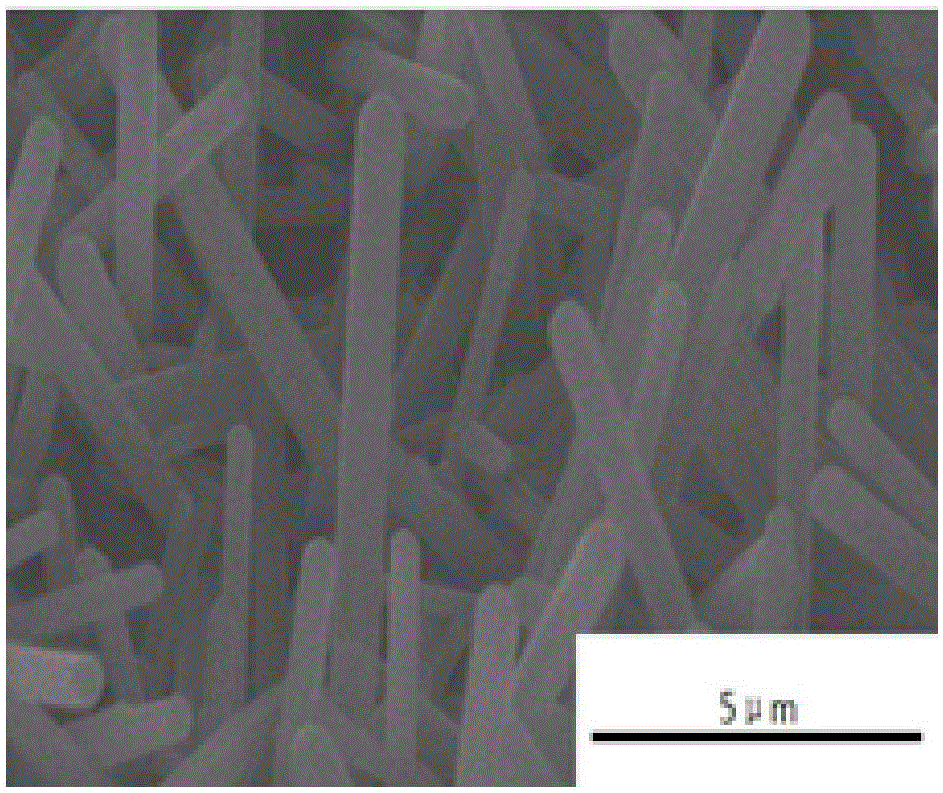

[0038] The morphology of the oriented porous silicon nitride ceramics prepared in Example 4 is as follows: figure 2As shown, it can be seen that the microstructure is mainly rod-shaped β-Si3N4 grains with high aspect ratio, which is conducive to the improvement of mechanical properties.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

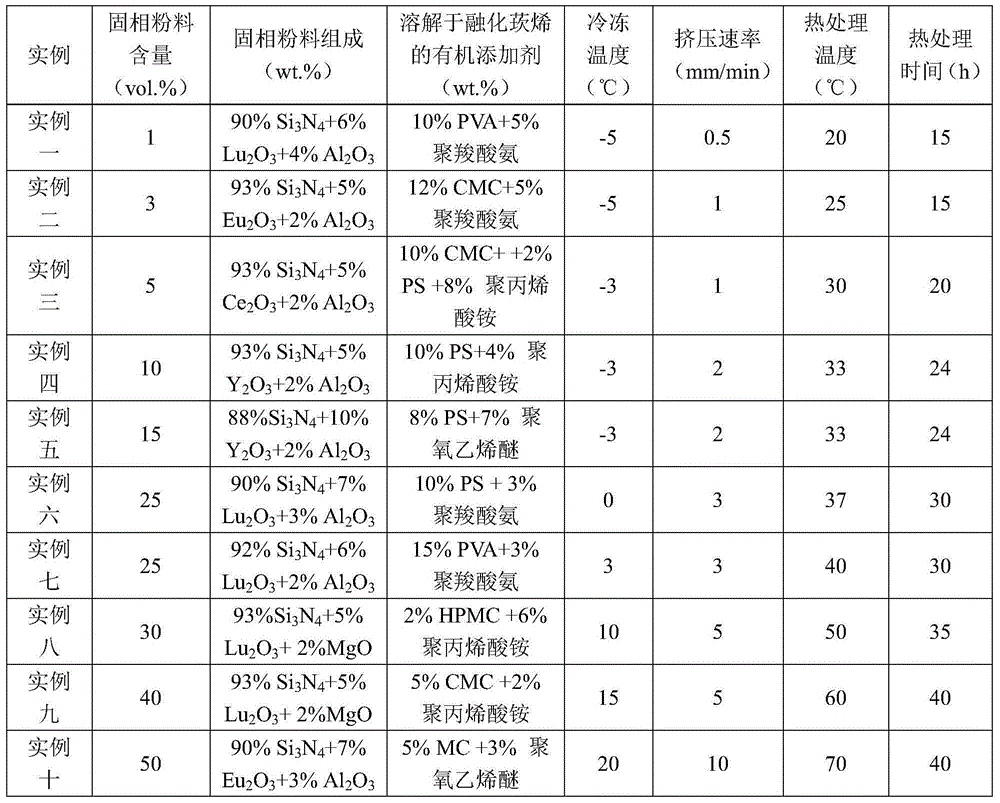

The invention discloses a method for extruding a frozen camphene / silicon nitride body to prepare oriented porous silicon nitride ceramic. The preparation method comprises the steps that firstly, solid powder obtained by mixing a sintering additive and silicon nitride powder and a certain amount of molten camphene dissolved with an organic addition agent are mixed to obtain uniform systematic slurry; secondly, the uniform systematic slurry is subjected to oriented freezing to obtain the frozen body, the obtained frozen body is subjected to heat treatment and then is extruded at certain rate, and then vacuum drying is performed to obtain a green body of the highly-oriented porous silicon nitride ceramic; sintering is performed in the nitrogen protection atmosphere to obtain the oriented porous silicon nitride ceramic after heating and glue discharging. The preparation method has the advantages that a preparation process is simple, the orientation degree of a prepared sample is high, porosity is high and the quality of the ceramic is easy to control.

Description

technical field [0001] The invention relates to the field of porous silicon nitride ceramics, in particular to a method for preparing oriented porous silicon nitride ceramics by extruding a camphene / silicon nitride frozen body. Background technique [0002] Oriented porous materials have attracted attention from various fields in recent years because of their functionality that traditional materials do not have. Among them, freezing the liquid ceramic slurry to grow "ice crystals" along the freezing direction, and then removing the "ice crystals" is currently the most effective method for preparing oriented porous materials. At present, it has been reported that oriented porous alumina and silicon carbide materials have been successfully prepared by freeze-drying with water, camphene, tert-butanol, etc. Different from the traditional freeze-drying technology, the plasticity and rheological properties of the camphene-based frozen body can further improve the orientation of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B38/06C04B35/584C04B35/632

Inventor 于方丽白宇倪澍李杨吴兴萍徐海

Owner 西安晶科立芯半导体设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com