Polyte α-olefin synthetic oil catalyst and preparation method

A technology for olefin synthesis oil and catalyst, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of simple preparation, high yield and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

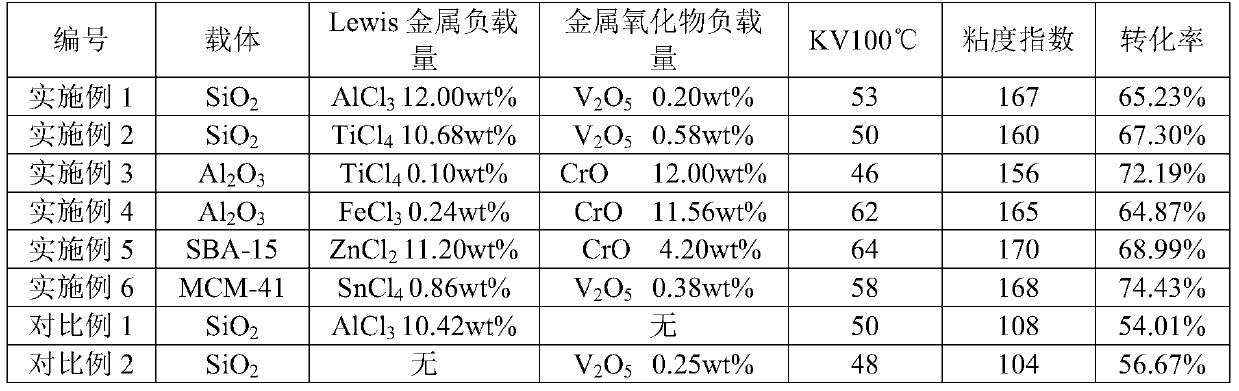

Examples

Embodiment 1

[0037] 8g silica (pore volume is 0.50cm 3 / g, the average pore diameter is 2.0nm, and the specific surface area is 158m 2 / g) impregnated in an aqueous solution of vanadium nitrate (V load is 0.20wt%), continuously stirred and impregnated in a water bath at 25°C for 30min, filtered, and dried in vacuum at 100°C for 6h; the silica carrier impregnated with vanadium nitrate was placed in a muffle For roasting in the furnace, the temperature was first raised to 120°C and kept at a constant temperature for 2 hours, then the temperature was raised to 350°C and kept at a constant temperature for 1 hour, then the temperature was further raised to 450°C and kept at a constant temperature for 6 hours, and finally the temperature was naturally lowered and cooled under nitrogen. The obtained sample was impregnated again in a toluene solution of aluminum trichloride (12.00wt% Al loading), impregnated with continuous stirring at room temperature for 2 hours, and vacuum-dried at 100°C for 6 ...

Embodiment 2

[0039] 8g silica (pore volume is 0.58cm 3 / g, the average pore diameter is 12.5nm, and the specific surface area is 100m 2 / g) impregnated in an aqueous solution of vanadyl oxalate (V loading capacity is 0.58wt%), continuously stirred and impregnated in a water bath at 45°C for 50min, filtered, and dried in vacuum at 100°C for 6h; the silica carrier impregnated with vanadyl oxalate was placed on Roasting in the muffle furnace, the temperature was first raised to 120°C, kept at a constant temperature for 2 hours, then raised to 350°C, held at a constant temperature for 1 hour, continued to be heated to 450°C, held at a constant temperature for 6 hours, and finally cooled naturally under nitrogen. The obtained sample was impregnated again in an isopropanol solution of titanium tetrachloride (Ti loading was 10.68wt%), impregnated with continuous stirring at room temperature for 2 hours, and vacuum-dried at 100°C for 6 hours to obtain a catalyst for storage until use.

Embodiment 3

[0041] 10g of aluminum oxide (γ-alumina, the pore volume is 1.34cm 3 / g, the average pore diameter is 20nm, and the specific surface area is 220m 2 / g) impregnated in chromium acetate aqueous solution (Cr loading capacity is 12.00wt%), continuously stirred and impregnated in 25°C water bath for 60min, filtered, and dried in vacuum at 100°C for 6h; the aluminum oxide carrier impregnated with chromium acetate was placed in Roasting in the Fu furnace, first raise the temperature to 120°C, keep the temperature for 2h, then raise the temperature to 350°C, keep the temperature for 1h, continue to raise the temperature to 550°C, keep the temperature for 6h, and finally cool down naturally under nitrogen to 200-300°C, and introduce reducing Gas CO lasts for 1-3 hours to reduce the contained chromium oxides to low-priced chromium oxides. The obtained sample was impregnated again in an isopropanol solution of titanium tetrachloride (Ti loading was 0.10wt%), impregnated with continuous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com